Processing method and processing device of enteromorpha products

The invention relates to a processing device and a technology for prolifera, which are applied in the field of processing methods and devices for prolifera products, and can solve the problems that affect the color, aroma, taste, and impurities of dishes, which are difficult to be completely removed, and are easy to stick to each other and dry. Good taste and salt reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

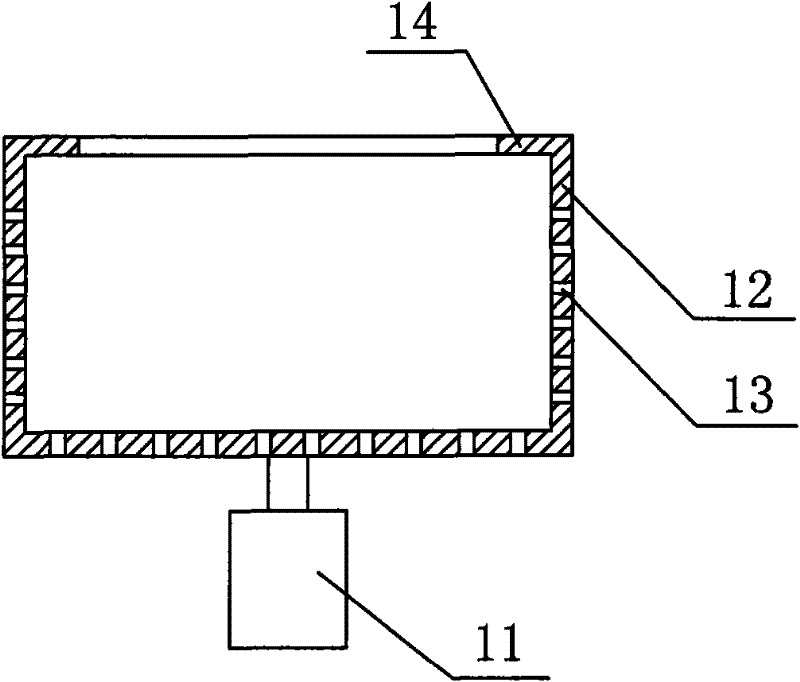

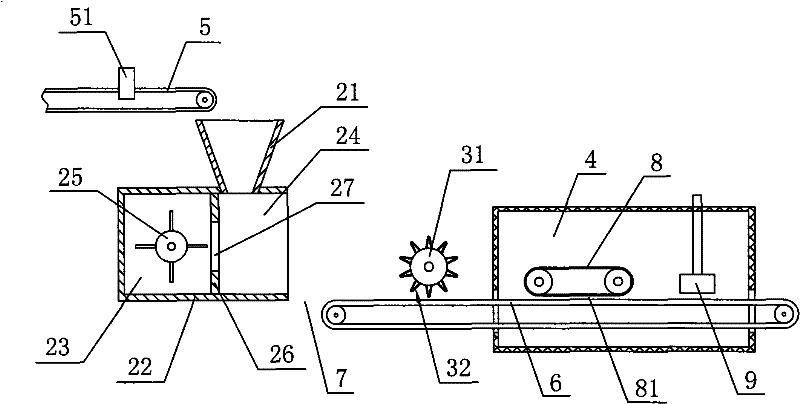

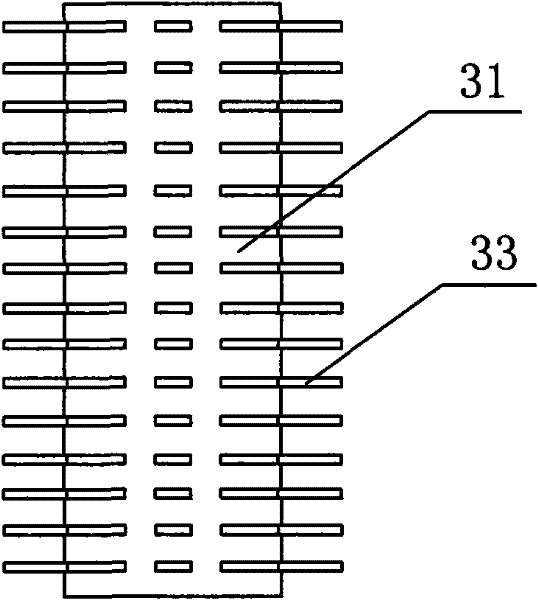

[0026] Embodiment 1: As shown in the figure, a processing device for Enteromorpha products includes a centrifugal dehydrator, a sand separation device, a carding device, a drying tunnel 4, a first conveyor belt 5 and a second conveyor belt 6, and the centrifugal dehydrator Comprising a first drive motor 11 and a dehydration bucket 12 with an upper end opening, the output shaft of the first drive motor 11 is fixedly connected with the bottom of the dehydration bucket 12, and the bottom and sides of the dehydration bucket 12 are provided with a plurality of dehydration holes 13, the dehydration bucket 12 The upper end is fixedly provided with an annular stop plate 14. The sand separation device includes a funnel 21 and a housing 22 with a rear opening. The funnel 21 is fixedly arranged at the upper end of the housing 22 and communicates with the second half 24 of the housing 22. , the first conveyor belt 5 is arranged on the top of the funnel 21, the first conveyor belt 5 is prov...

Embodiment 2

[0028] Embodiment two: a kind of method utilizing the processing device of embodiment one to process enteromorpha product, it may further comprise the steps:

[0029] (1), remove the grass, bamboo chips, shells, large stones and other sundries in the freshly collected Enteromorpha, and clean the Enteromorpha in the existing cleaning device. The cleaning steps are: water injection-stirring cleaning-changing water - stir to wash - drain;

[0030] (2), the Enteromorpha subpackage is in the plastic net bag that a plurality of mesh diameters are 1.5 centimetres, then the plastic net bag that Enteromorpha is housed is put into the dehydration barrel 12 of centrifugal dehydrator and dehydrates 5 minutes, dehydration barrel The rotating speed of 12 is 3000 rpm, and 50%-65% of the moisture in the enteromorpha is removed;

[0031] (3), pour out Enteromorpha from plastic mesh bag, put on the first conveyer belt 5 in an orderly manner after straightening out, and utilize automatic cuttin...

Embodiment 3

[0035] Embodiment three: a kind of method utilizing the processing device of embodiment one to process enteromorpha product, it comprises the following steps:

[0036] (1), remove the grass, bamboo chips, shells, large stones and other sundries in the freshly collected Enteromorpha, and clean the Enteromorpha in the existing cleaning device. The cleaning steps are: water injection-stirring cleaning-changing water - stir to wash - drain;

[0037] (2), the Enteromorpha subpackage is in the plastic net bag that a plurality of mesh diameters are 1.5 centimetres, then the plastic net bag that Enteromorpha is housed is put into the dehydration bucket 12 of centrifugal dehydrator and dehydrated for 7 minutes, dehydration bucket The rotating speed of 12 is 2000 rpm, and 50%-65% of the moisture in the enteromorpha is removed;

[0038] (3), pour out Enteromorpha from plastic mesh bag, put on the first conveyer belt 5 in an orderly manner after straightening out, and utilize automatic c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com