Method for preparing fuel ethanol by low-energy consumption wood raw material

A technology of fuel ethanol and low energy consumption, applied in the field of enzymatic hydrolysis, which can solve unseen and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

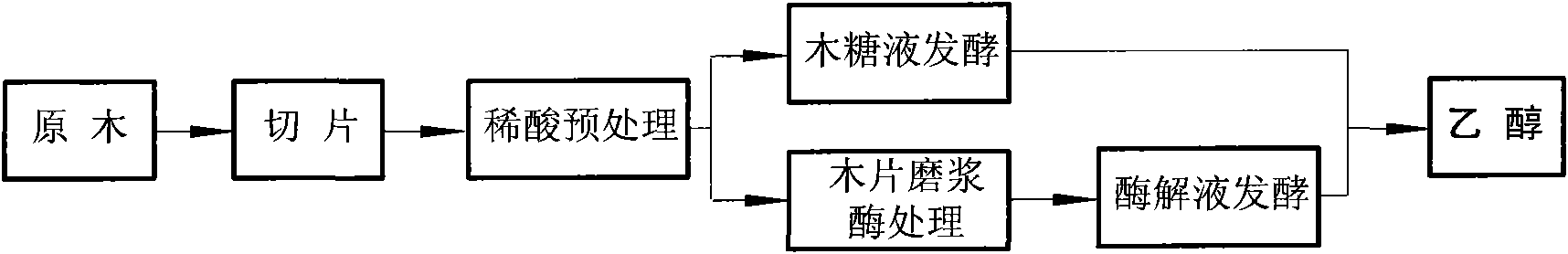

[0017] Wood raw materials, such as poplar, are peeled and sliced into log chips with a length, width, and thickness of about 30mm×15mm×5mm by a spiral disc mechanical chipper, and are stacked and stored after air-drying.

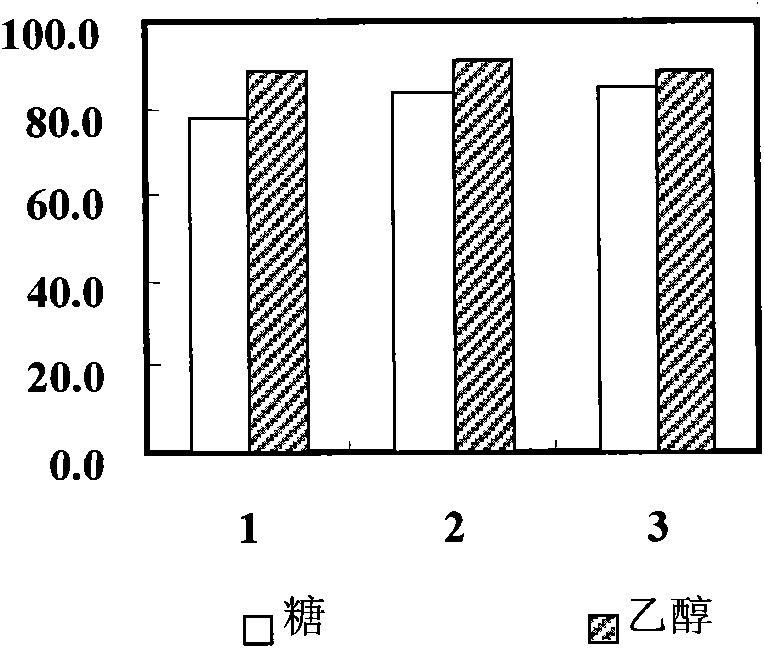

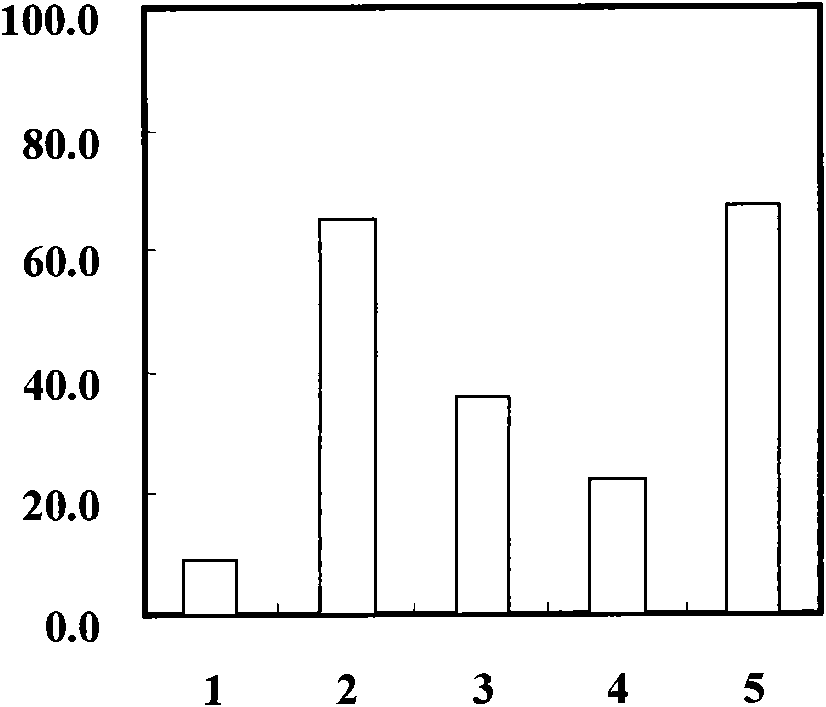

[0018] a. In the intermittent stainless steel corrosion-resistant electric heating rotary cooker, add log chips, add 0.5-2.0% (w / w) dilute sulfuric acid according to the solid-to-liquid ratio of 1:8-10 (w / v), and seal the cooking pot , adjust the gyration rate to 1-1.5 rpm, and react at 145-160° C. for 0.5-2.0 h. After the reaction is over, the reactant is filtered through a stainless steel filter to obtain wood chips and xylose liquid. Wash the wood chips with water at 1:5-10 (w / v) to pH 4.8-5.0 to obtain a dilute xylose solution, which is used for the next round of gradient washing of the wood chips. The yield of xylose reaches more than 80.0% of the raw material xylan, the filtering and washing speed of wood chips is higher than that of wood chips by m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com