Diamond-like carbon coated glass and preparation method thereof

A technology of diamond-like film and coated glass, applied in chemical instruments and methods, glass/slag layered products, sputtering coating, etc., can solve the problems of hard-to-degrade solid waste, PE organic protective film requiring manual peeling, etc. The film surface has a uniform appearance, good protection effect and high hardness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

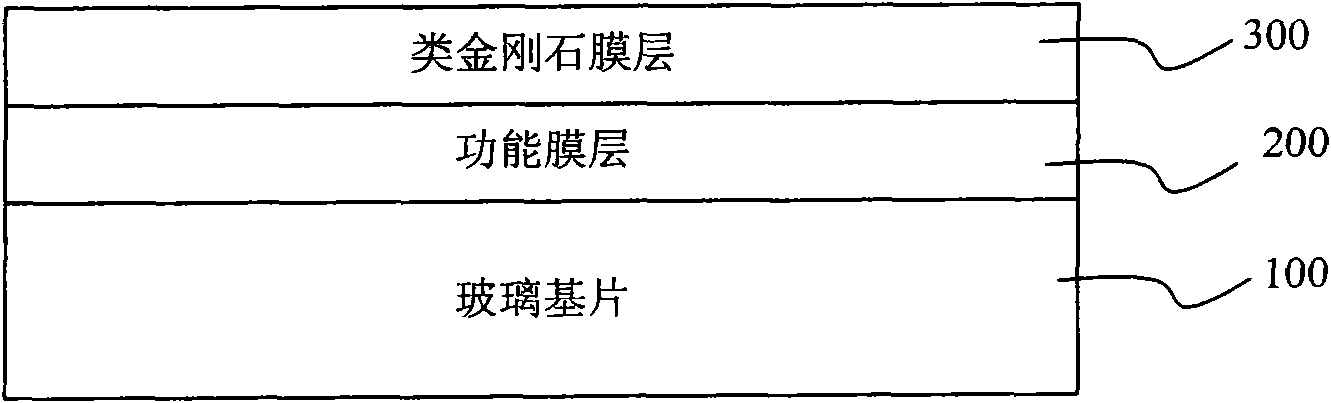

[0065] In addition, the present invention provides a preparation method of the diamond-like coated glass, Figure 6 It is a schematic flow sheet of the diamond-like coated glass preparation method of the present invention, as Figure 6 As shown, the method includes the following steps:

[0066] Step 1: providing a glass substrate;

[0067] Step 2: Depositing a functional film layer on the surface of the glass substrate;

[0068] Step 3: Deposit a type of diamond film on the surface of the functional film.

[0069] Wherein, in the step 2 and step 3, there is no specific limitation on the deposition process and the process parameters of the deposition process, wherein, various known deposition methods capable of depositing each film layer can be selected, for example, chemical vapor deposition and cathode Deposition by arc evaporation, etc. In the embodiment of the present invention, all film layers are deposited by magnetron sputtering. At the same time, for various known d...

Embodiment 1

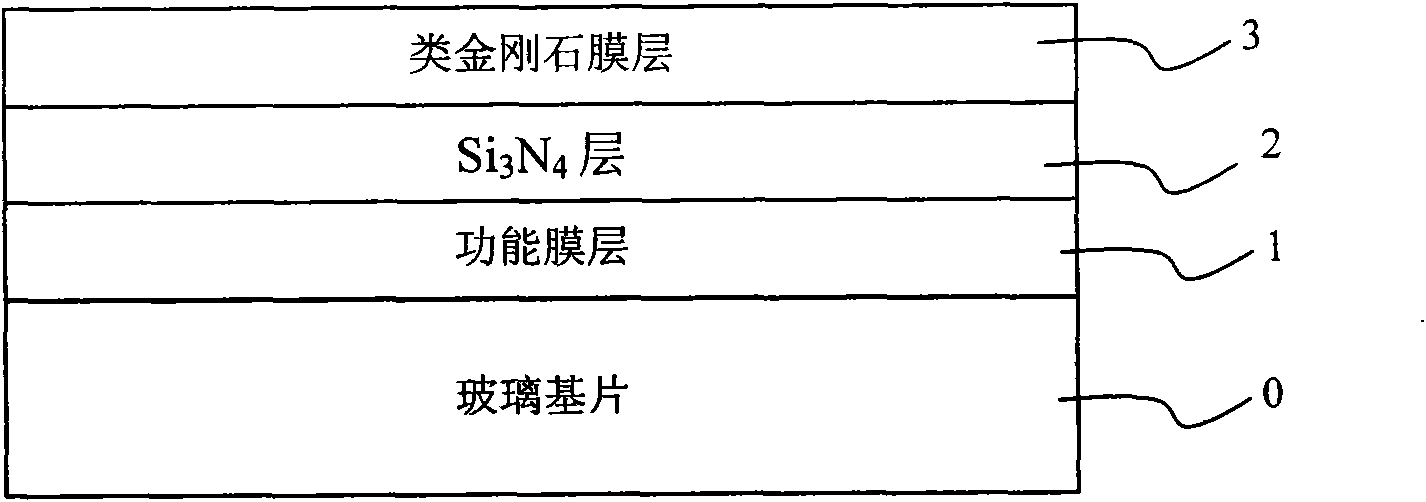

[0093] The present invention is prepared by conventional vacuum magnetron sputtering equipment, and the vacuum series after the process gas is introduced is guaranteed to be 10 -3 Under the condition of mbar-level working atmosphere, use fresh (production date no more than two months) raw construction-grade floats for plating.

[0094] like figure 2 , on the glass substrate 0, a multi-layer functional film layer 1 is plated, and the inner layer of the functional film layer may include TiO 2 layer, NiCr layer, Ag layer, Cu layer, SiO 2 layer, ZnO layer, SnZnO 3 layer and other conventional film materials, and the outer layer 2 is plated with Si 3 N 4 , forming Si 3 N 4 layer, its sputtered thickness can be 10-120nm.

[0095] DLC layer 3: on Si 3 N 4 On the outside of the layer, using a graphite target, sputter an oxide layer C with a thickness of 15-20 nm in an argon gas atmosphere, under the condition of an argon flow rate of 1200 sccm, and a sputtering power of 8 KW...

Embodiment 2

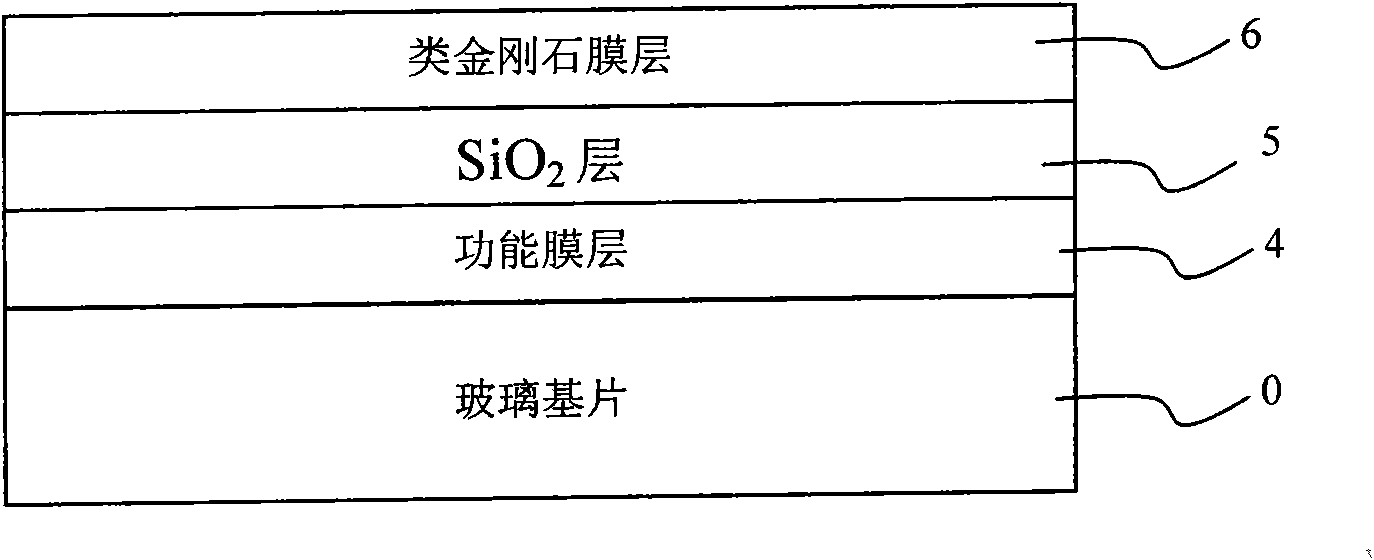

[0106] The present invention is prepared by conventional vacuum magnetron sputtering equipment, and the vacuum series after the process gas is introduced is guaranteed to be 10 -3 Under the condition of mbar-level working atmosphere, use fresh (production date no more than two months) raw construction-grade floats for plating.

[0107] like image 3 , on the glass substrate 0, one or more layers of functional film layer 4, including SnO 2 layer, SiO 2 layer, TiO 2 layer, coated with SiO on the outer layer 5 2 layer, its sputtered thickness can be 20-110nm.

[0108] The outermost protective film layer, that is, the diamond-like film layer 6: in SiO 2 On the outside of the layer, using a graphite target, sputter an oxide layer C with a thickness of 15-20 nm in an argon gas atmosphere, under the condition of an argon flow rate of 1200 sccm, and a sputtering power of 8 KW. After the diamond-like carbon film is plated, the wear resistance and oxidation resistance of the subst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com