Polyurethane nanometer powder for surface phosphoric acid modification and preparation method thereof

A technology of nano-powder and polyurethane, which is applied in the field of surface phosphoric acid-modified polyurethane nano-powder and its preparation, which can solve the problems of high surface energy, large specific surface area of nano-powder, inconvenient preparation, storage and application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1、200

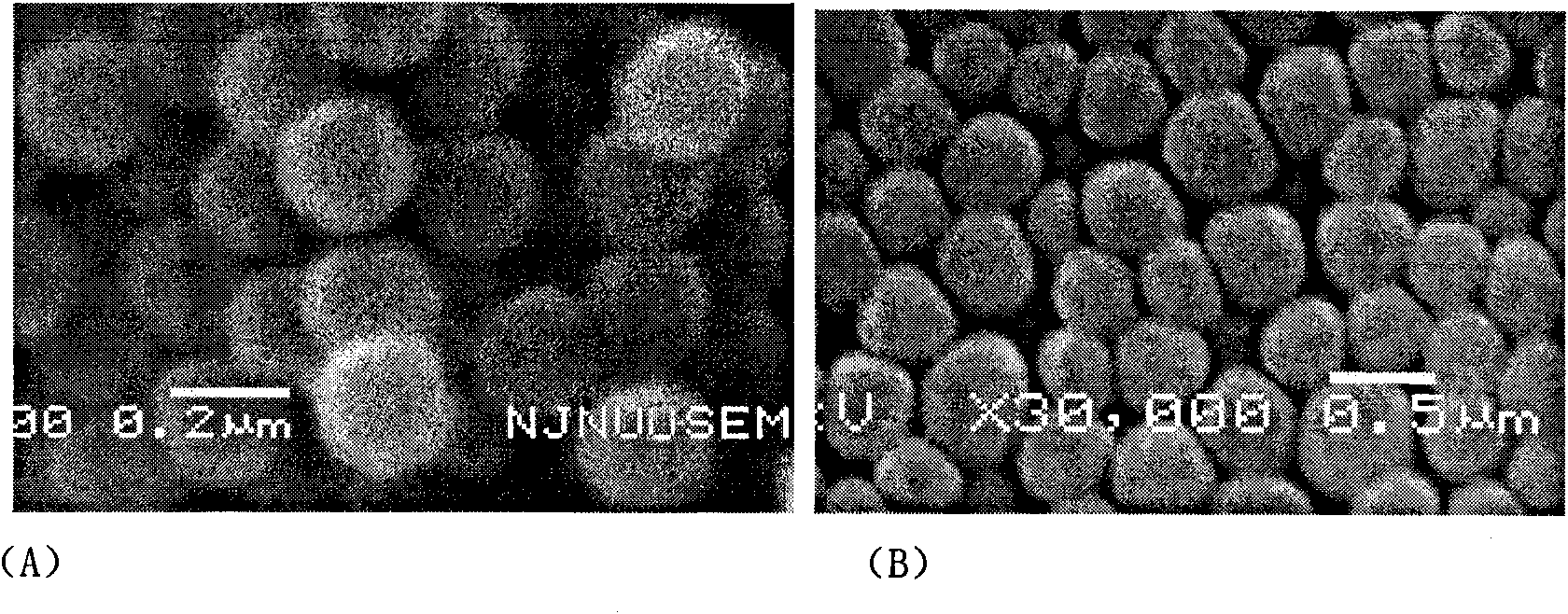

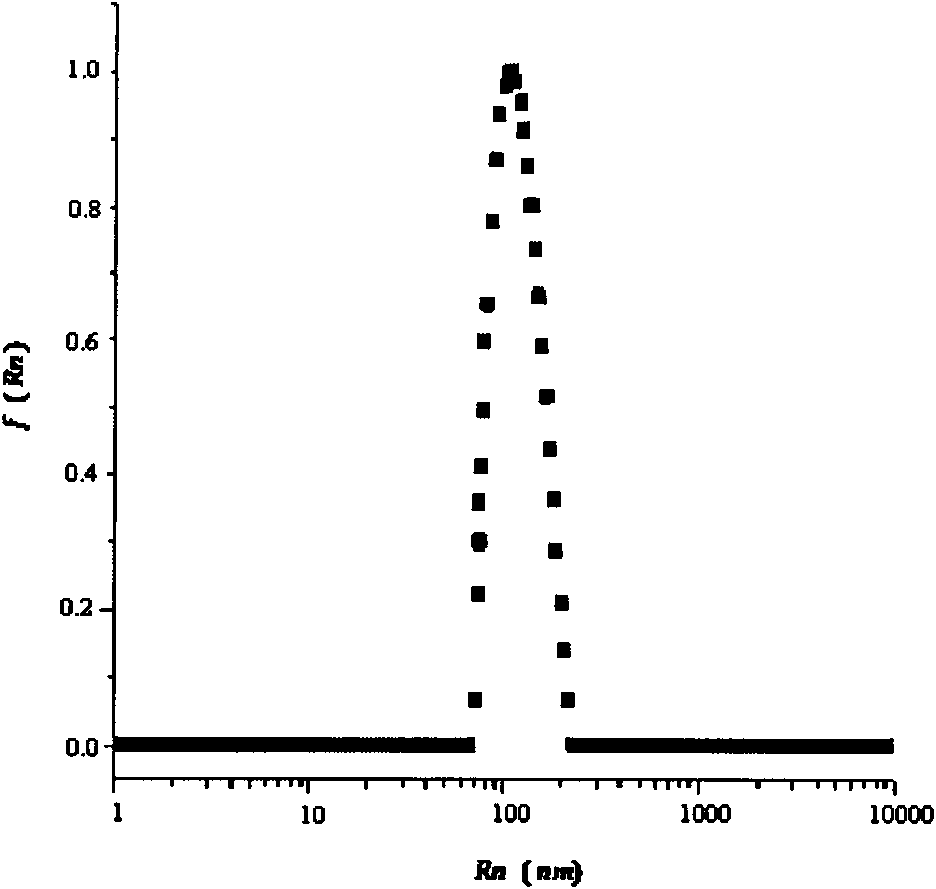

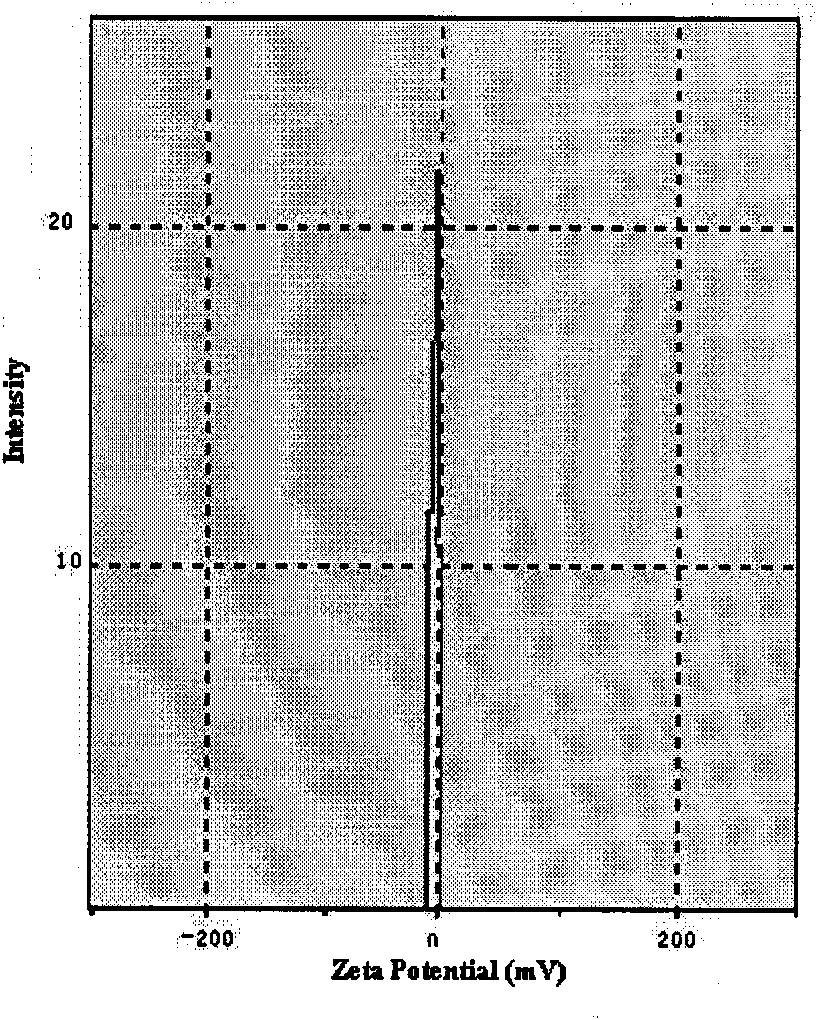

[0023] Example 1, Polyurethane nano-powder with a particle size of about 200nm phosphoric acid surface modification and its preparation

[0024] Pour 4.2 g of diphenylmethane diisocyanate (MDI) dissolved in 200 ml of ethyl acetate and 7.5 g of polytetrahydrofuran (PTMG, 2000) in a molten state into a container equipped with a condenser tube, a mechanical stirrer, a nitrogen outlet, and a thermometer. In the four-necked flask, add the N-methylpyrrolidone (NMP) solution (6% solution, wherein DMPA0.9g) of dihydroxyethylpropionic acid (DMPA) dropwise, under the protection of nitrogen, at a temperature of 80°C, mechanically stir the reaction After 3 hours, add excess isopropanol or n-butanol to block, then add triethylamine to adjust the pH of the solution to neutrality, add dropwise 50ml of deionized water containing 10% sodium dodecylsulfonate and vigorously stir and emulsify to obtain nano water-based emulsion. Add 0.2 mol / L pH=7.0 phosphate buffer solution and toluene (the vol...

Embodiment 2、50

[0027] Example 2, 50nm, 400nm, 500nm or so particle size phosphoric acid surface modified polyurethane nanopowder and its preparation

[0028] The surfactant dosage added in the emulsification process of embodiment 1 is adjusted to 20%, 4% and 2% concentration respectively, and all the other reagent types, consumption and steps are all the same with embodiment 1, obtain average particle diameter and be respectively 50nm, 400nm (see figure 1 B) and 500nm phosphoric acid surface-modified polyurethane nanopowder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com