Magneto-strain displacement type needleless injector

A magneto-strain, needle-free technology, applied to syringes, injectors by jetting, infusion sets, etc., can solve the problems of multiple manufacturing processes, bulky volume, spring power attenuation, etc., and achieve clear technical routes, high response speed, and work The effect of low voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

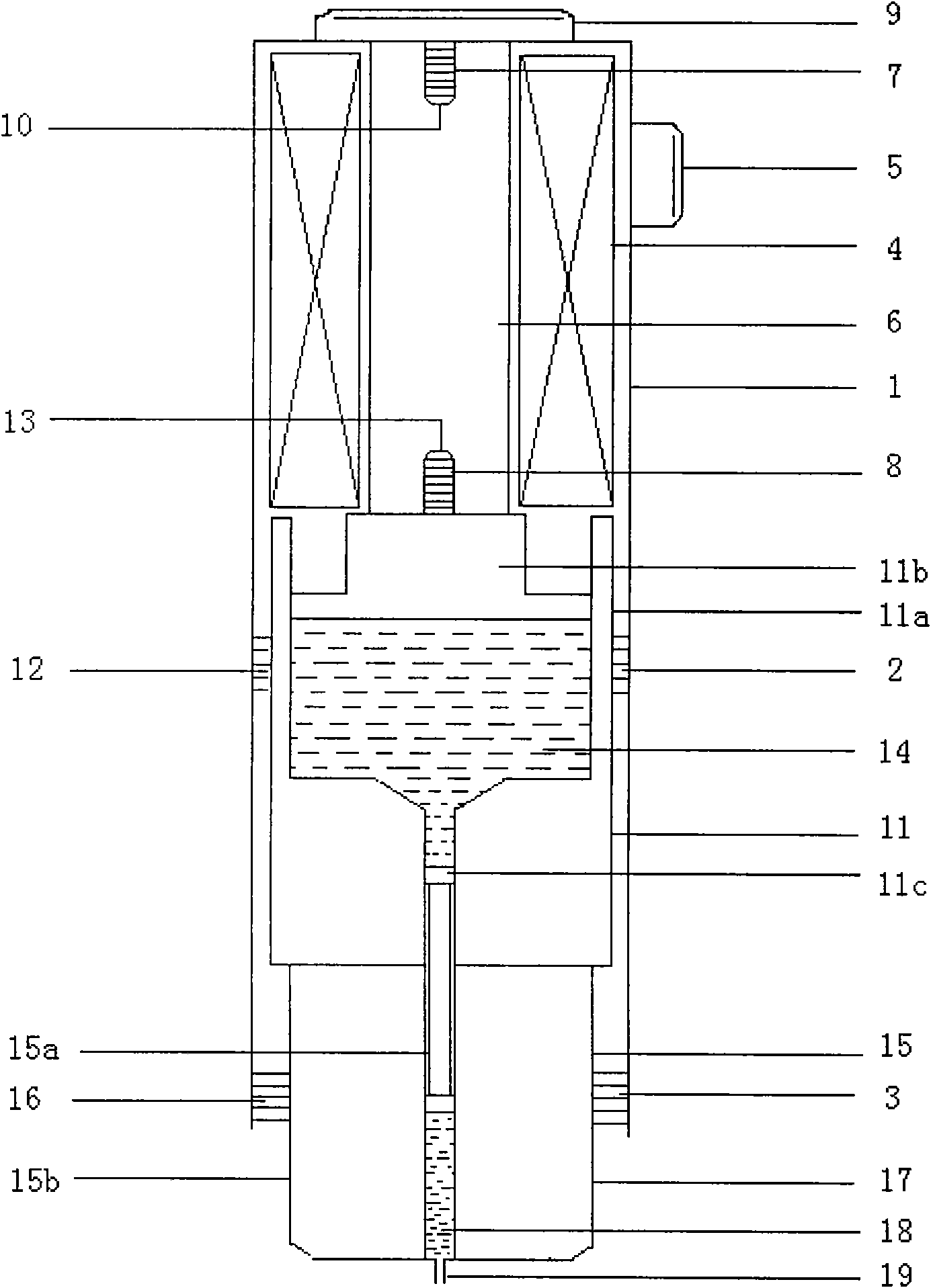

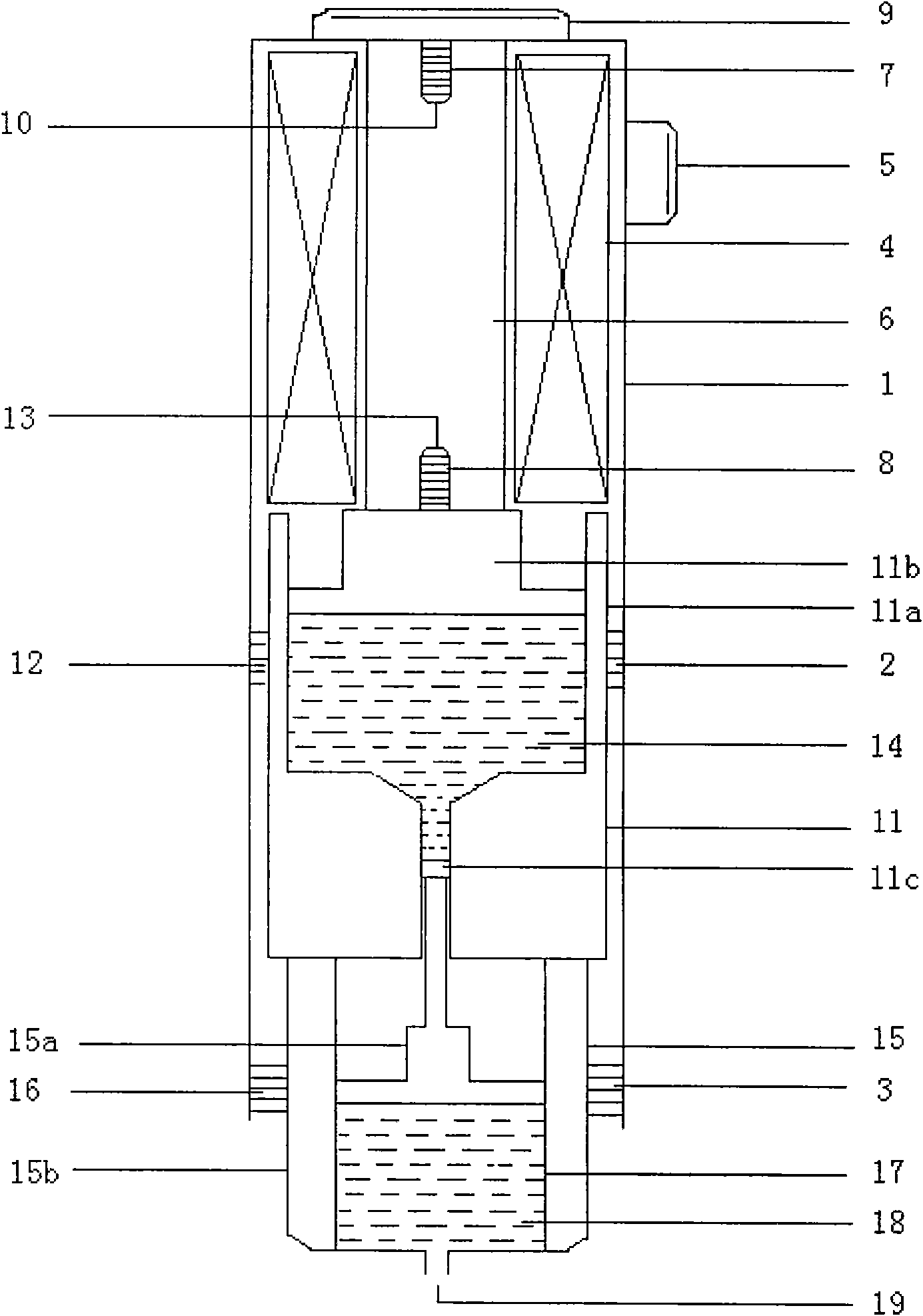

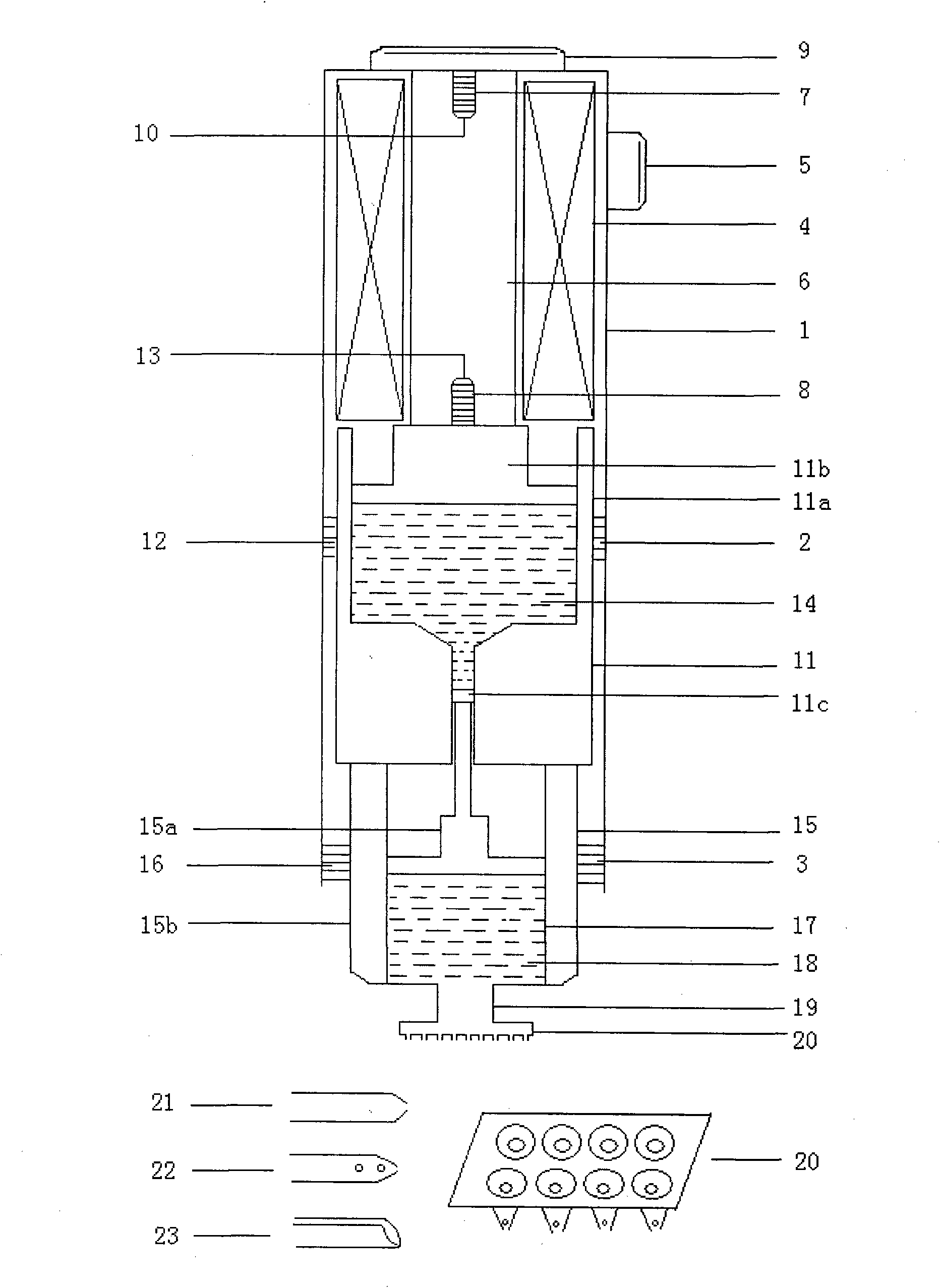

[0039] figure 1 In the shown embodiment, the cylinder body 1 is a tubular body made of stainless steel, the upper end is closed, but there is a round hole in the center, and the lower end is open. Internal threads 2 are engraved on the inner surface of the middle part of the cylinder body 1; internal threads 3 are engraved on the inner surface of the lower part. An electromagnetic coil 4 is disposed on the upper section inside the cylinder body 1, and the electromagnetic coil 4 is cylindrical and formed by winding an enamelled copper wire. A power port 5 is provided on the upper part of the outer wall of the cylinder body 1 , which can lead the electric current into the electromagnetic coil 4 . The electromagnetic coil 4 has a built-in magnetic rod 6, which has the function of magneto-induced strain and is made of Terfenol-D material. The magnetic rod 6 is a cylindrical entity or a hollow tubular structure with an outer diameter of 5-20mm, ensuring that it has sufficient mec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com