Magnetic Fe3O4 polymer submicron sphere prepared by hydro thermal method and application thereof

A polymer, sub-micron technology, applied in the preparation methods of peptides, chemical instruments and methods, organic chemistry, etc., can solve the problems of poor monodispersity and controllability, single use, and complicated preparation, and achieve good monodispersity. , uniform size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

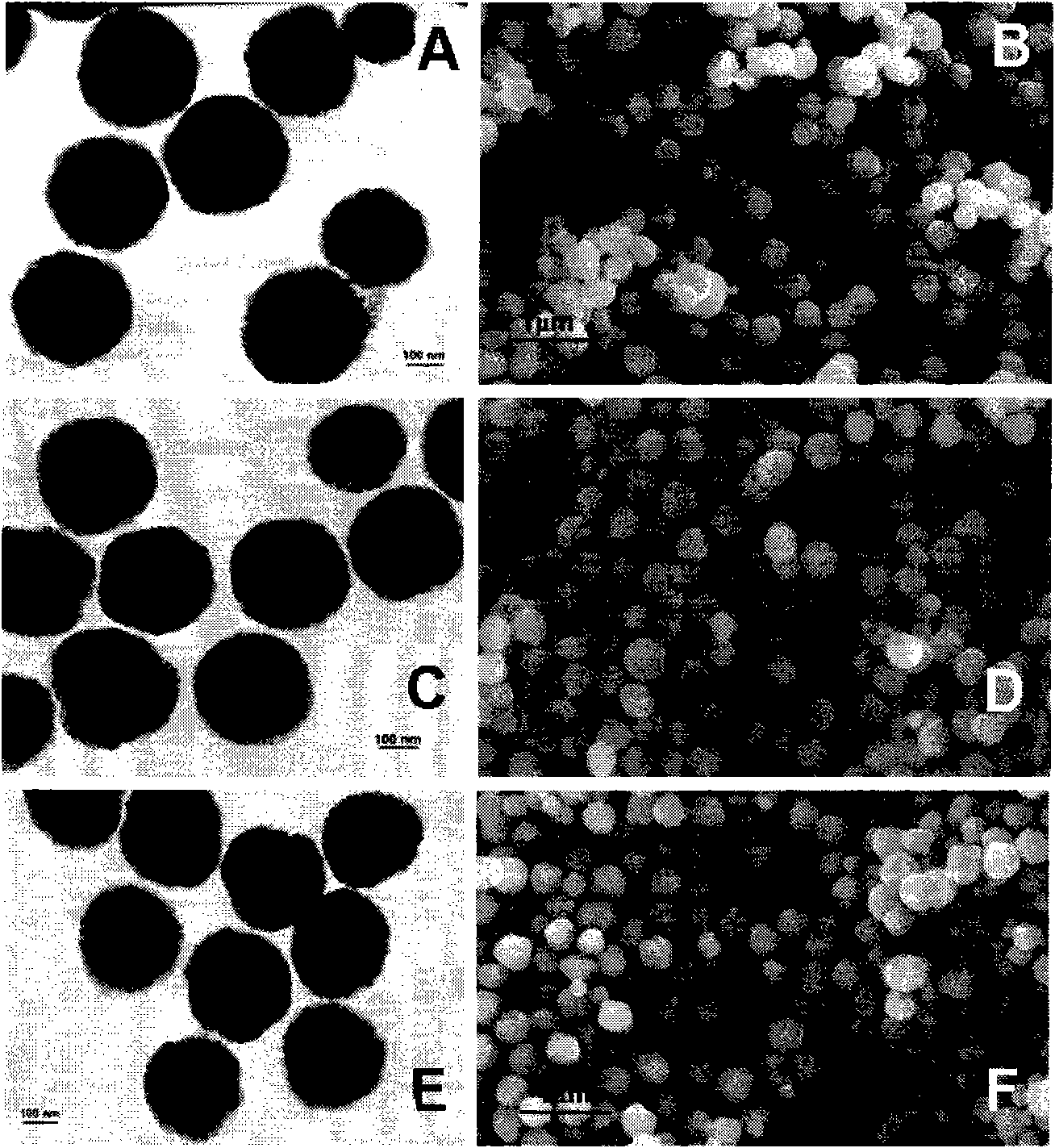

[0034] Step 1): Controllable preparation of magnetic Fe 3 o 4 Dextran magnetic Fe coated with dextran on the surface of the ball 3 o 4 Polymer submicron spheres.

[0035] Prepare 0.1mol / L FeCl 3 ·6H 2 O to the ethylene glycol solution, add anhydrous sodium acetate to make the final concentration 0.05mol / L, and then add dextran with a molecular weight of 10000 to make the final concentration 0.05mg / ml. The above mixture was placed in a closed reaction kettle and reacted for 25 hours at 100°C to obtain a solid magnetic Fe 3 o 4 Dextran magnetic Fe coated with dextran on the surface of the ball 3 o 4 Polymer submicron spheres.

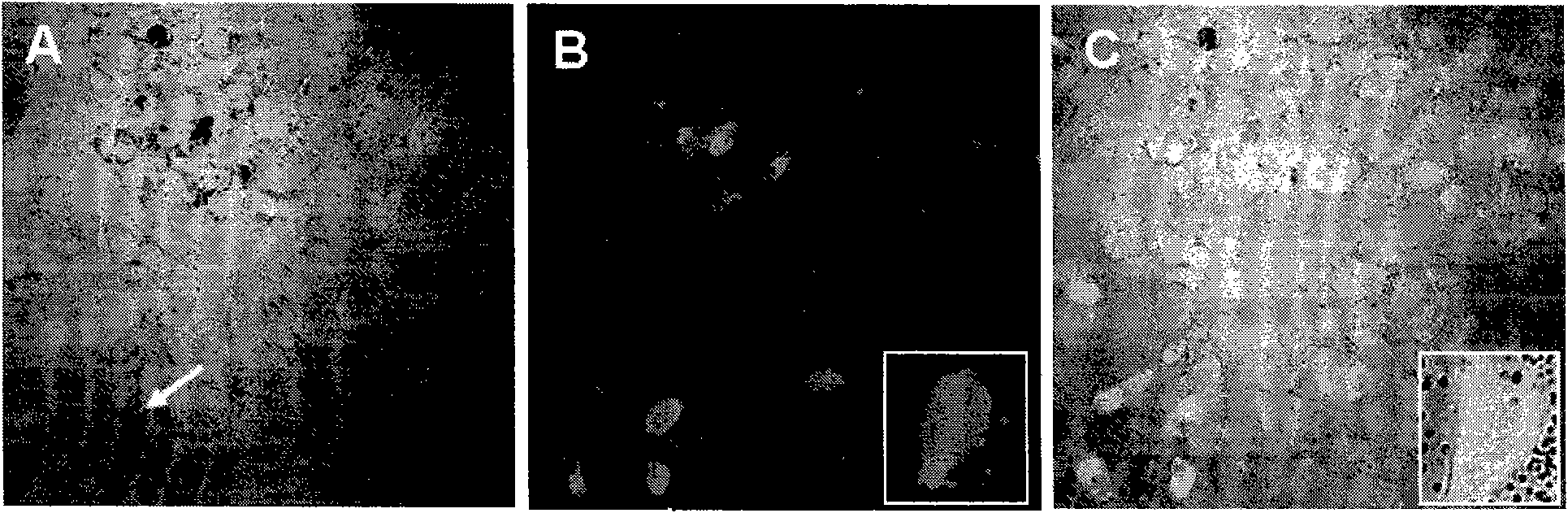

[0036] Step 2): the dextran magnetic Fe obtained in step 1) 3 o 4 Polymer submicron spheres carry FITC for multifunctionality and application in cell imaging.

[0037] The dextran magnetic Fe that 20mg step 1) obtains 3 o 4 Add polymer submicron spheres to 1 mg / ml green fluorescent dye FITC, stir at room temperature for 12 hours, and collect...

Embodiment 2

[0040] Step 1): Controllable preparation of magnetic Fe 3 o 4 Dextran Magnetic Fe 3 o 4 submicron spheres.

[0041] Prepare an ethylene glycol solution of 0.25 mol / L ferric nitrate, add anhydrous sodium acetate to make the final concentration 1 mol / L, and then add dextran with a molecular weight of 10,000 to make the final concentration 100 mg / ml. The above mixture was placed in a closed reaction kettle and reacted for 5 hours at 200 ° C to obtain a solid magnetic Fe 3 o4 Dextran magnetic Fe coated with dextran on the surface of the ball 3 o 4 Polymer submicron spheres.

[0042] Step 2): the dextran magnetic Fe obtained in step 1) 3 o 4 Polymer submicron spheres carry FITC for multifunctionality and application in cell imaging.

[0043] Add 20 mg of dextran magnetic submicron spheres obtained in step 1) to 1 mg / ml quantum dots, stir and react at room temperature for 12 hours, and collect dextran magnetic Fe with a magnet 3 o 4 Polymer submicron spheres were washed t...

Embodiment 3

[0046] Step 1): Controllable preparation of magnetic Fe 3 o 4 Spherical Chitosan-Coated Chitosan Magnetic Fe 3 o 4 submicron spheres.

[0047] Prepare 0.01mol / L FeCl 3 ·6H 2 O to the ethylene glycol solution, add anhydrous sodium acetate to make the final concentration 10mol / L, and then add chitosan with a molecular weight of 50000-800000 to make the final concentration 20mg / ml. The above mixture was placed in a closed reaction kettle and reacted at 150°C for 18 hours to obtain a solid magnetic Fe 3 o 4 Chitosan magnetic Fe coated with chitosan on the surface of the ball 3 o 4 Polymer submicron spheres.

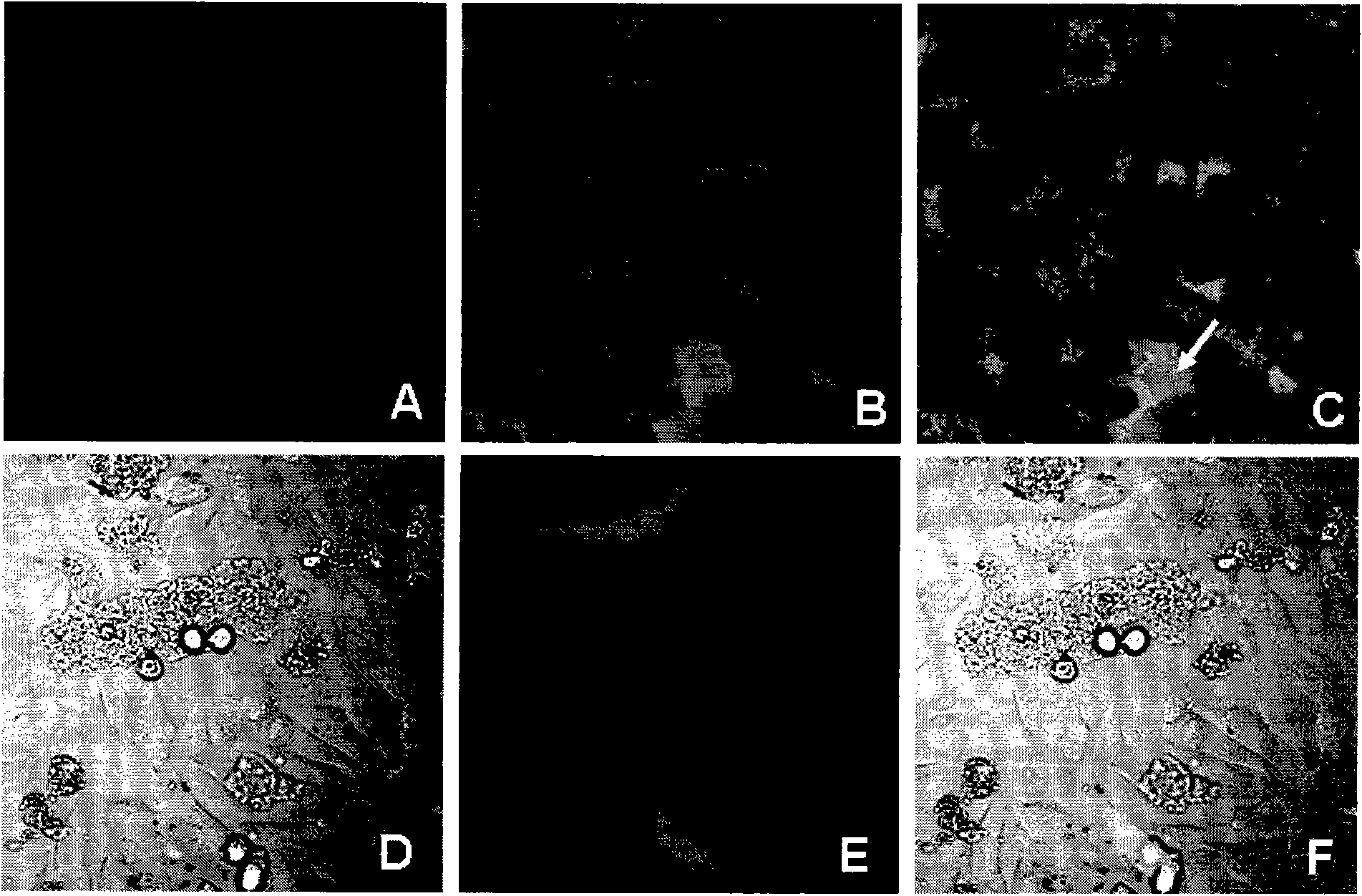

[0048] Step 2): the chitosan magnetic Fe that step 1) obtains 3 o 4 Multifunctionalization of polymer submicron spheres coupled with FITC and colocalization with lysosomes.

[0049] Colocalization with lysosomes: chitosan magnetic Fe 3 o 4 After polymer submicron spheres are covalently coupled to FITC, take 1 mg of chitosan magnetic Fe after covalently coupling ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com