New preparation method for chitin deacetylase

The technology of a deacetylase and a new method, which is applied in microorganism-based methods, biochemical equipment and methods, hydrolase, etc., can solve the problem of low enzyme activity, strict substrate requirements, and difficult industrial large-scale fermentation of fungi, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

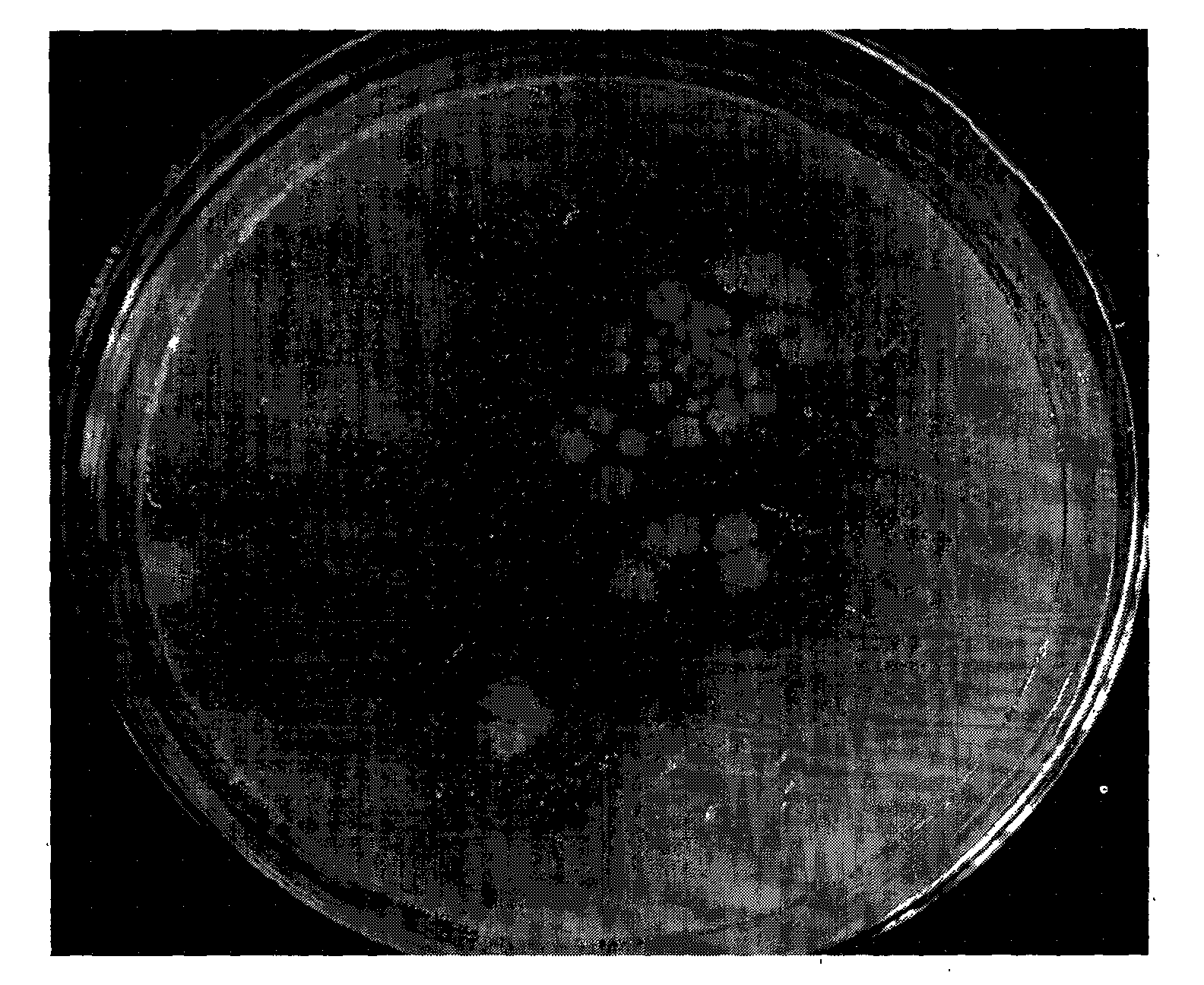

[0035] Example 1: (1) Flat plate coating: Soak the shrimp shell culture soil (obtained after burying freshwater shrimp shells in the pumpkin field and decomposing for 31 days) with 3 times the volume of sterile saline (containing 300ppm carbendazim) for 6 hours The supernatant was collected by filtration, spread on a beef extract-peptone plate (0.9% beef extract, 3% peptone, 0.15% NaCl, 2% agar, pH 7.2), and incubated at 37°C for 36 hours.

[0036] (2) Plate streaking: Select single colonies with different colony forms from the beef extract peptone plate, and separate them by streaking on the beef extract peptone plate.

[0037] (3) CDA activity verification: select a single colony with different colony morphology from the streaked plate to the PN-casein plate (0.5% casein, 0.1% K 2 HPO 4 , 0.1% KH 2 PO 4 , 0.05% MgSO 4 , 2% agar, 0.1% PN), and cultured at 37°C for 48h. Select the colony that makes the medium turn yellow (the colorless PN acetyl group is removed and then co...

example 2

[0038] Example 2: (1) liquid fermentation: the bacterial strain obtained by purification is inoculated into casein culture fluid (0.5% casein, 0.1% K 2 HPO 4 , 0.1% KH 2 PO 4 , 0.05% MgSO 4 ), and cultured with shaking at 37°C for 48h, centrifuged (3000g×15min) to collect the supernatant.

[0039] (2) Verification of CDA activity: transfer an appropriate amount of supernatant to small wells on a PN-casein plate, and after incubating at a constant temperature at 37°C for 48 hours, it is found that yellow is formed around the small wells.

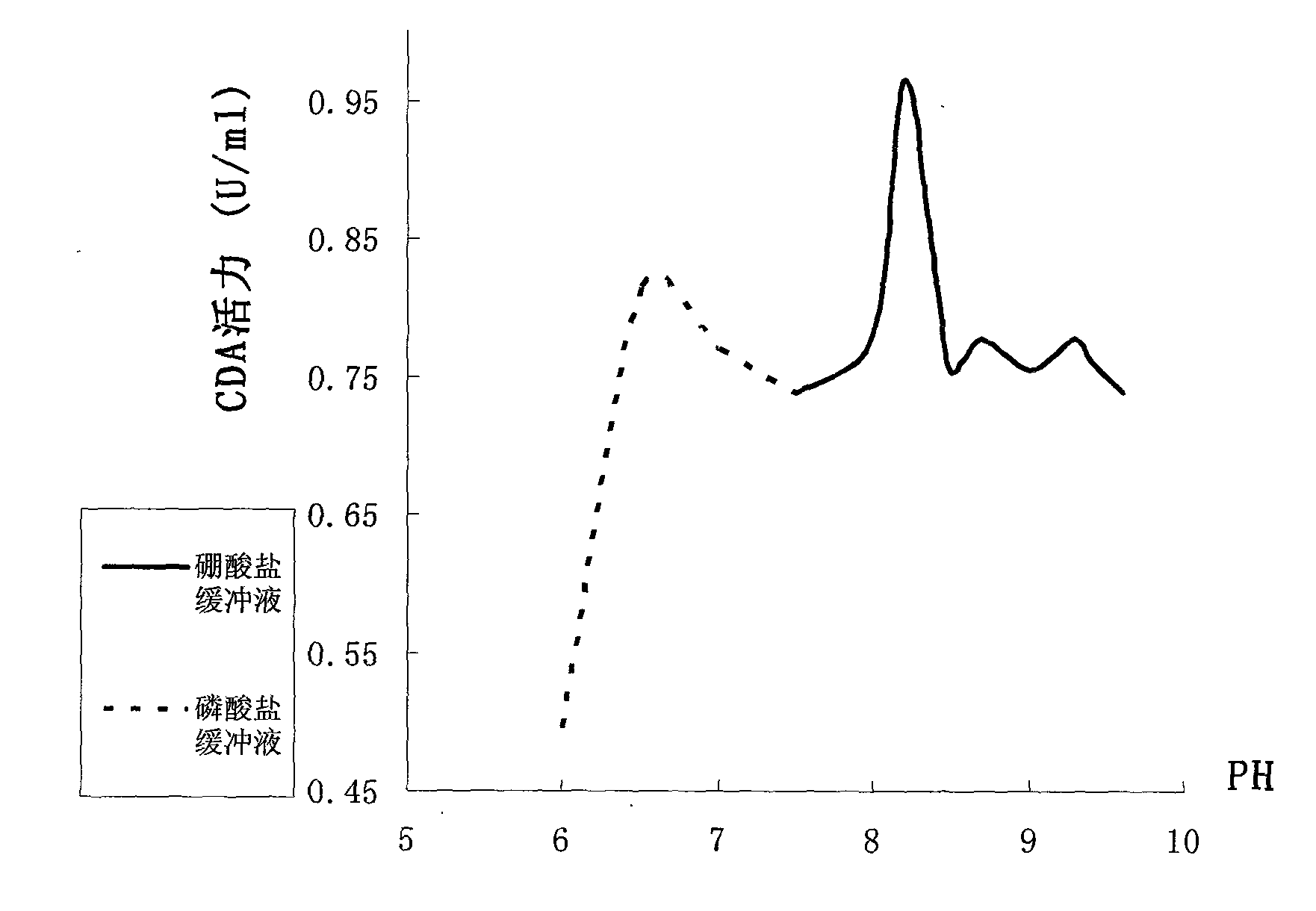

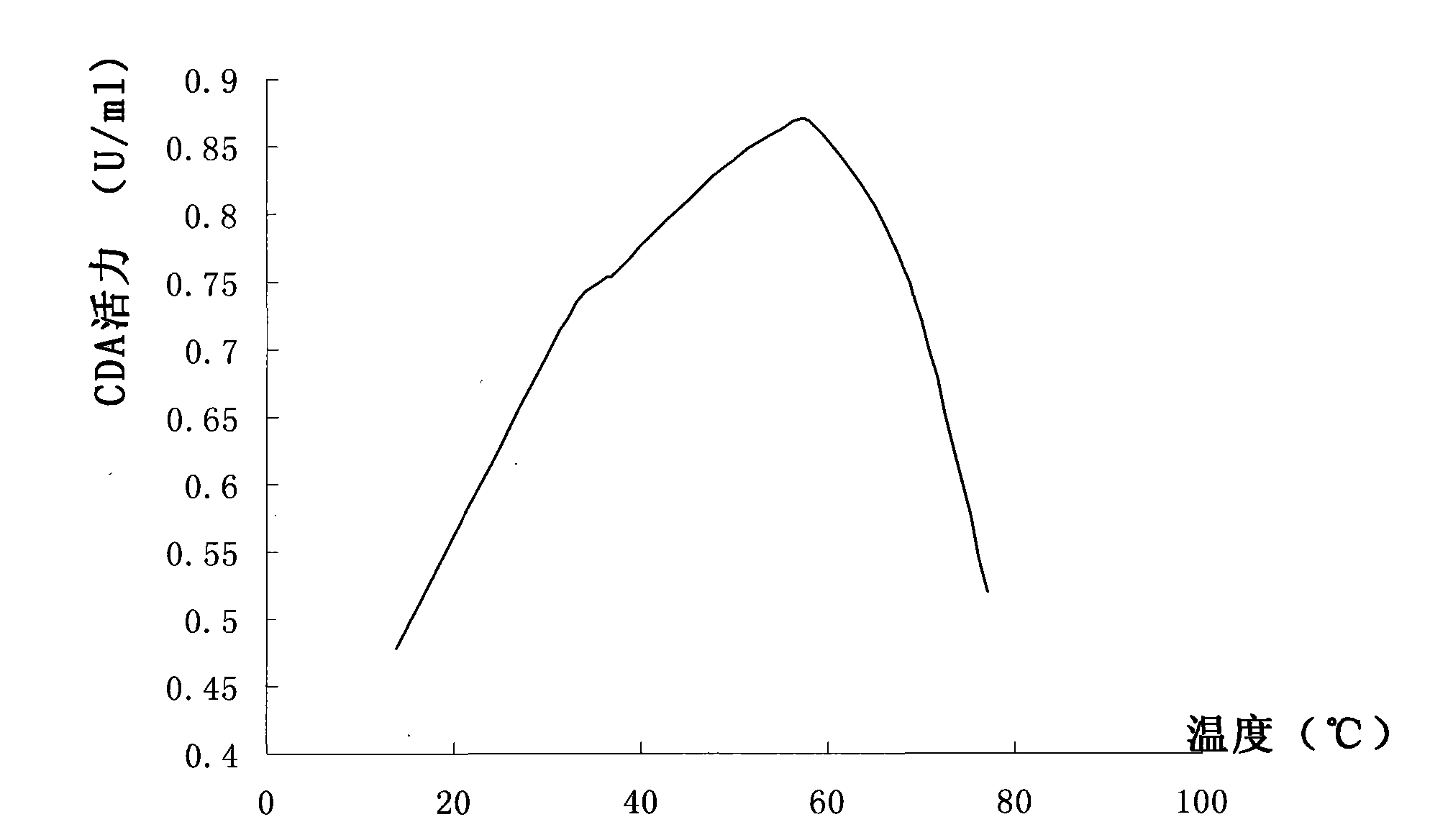

[0040] (3) Determination of CDA activity: Refer to the Araki and Ito (1975) method to measure the CDA activity of the supernatant: 1 unit of enzyme activity is defined as the amount of enzyme required to remove 1 μmol of acetyl from acetylated EGC per minute, which is equivalent to The amount of enzyme required to produce 1 μmol of glucosamine per minute; use glucosamine hydrochloride as a standard curve to quantitatively measure the abil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com