Cloth cathode assembly for microbiological fuel cell and preparation method thereof

A technology for fuel cells and cathode components, applied in the direction of biochemical fuel cells, battery electrodes, electrical components, etc., can solve the problems of complex preparation process, poor mechanical properties, and expensive materials, and achieve simple manufacturing process, good mechanical properties, and easy operation simplified effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

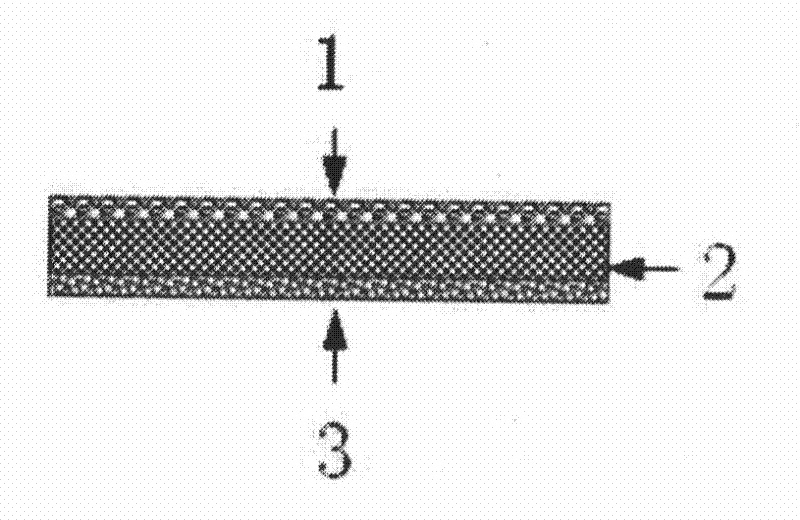

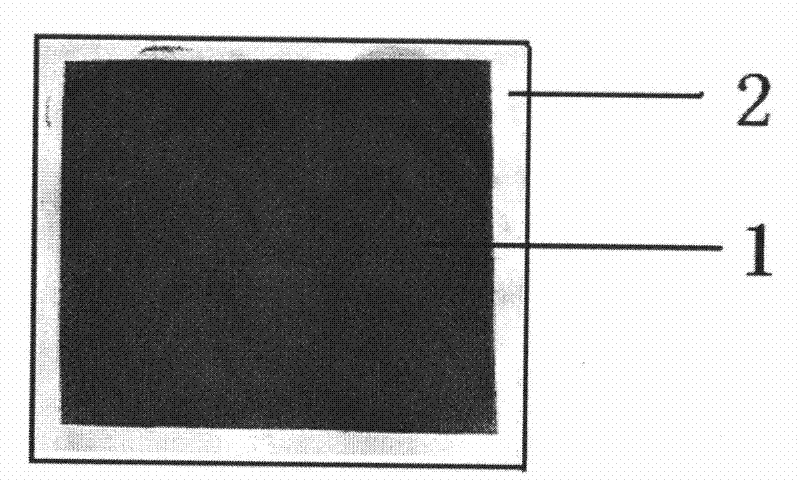

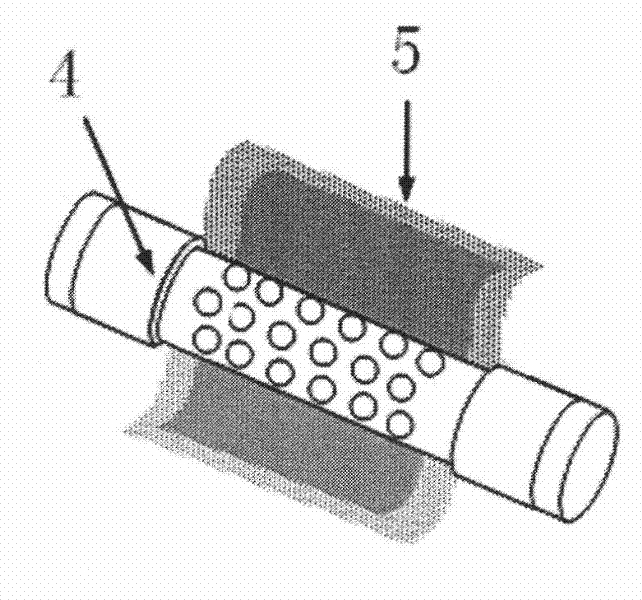

[0040] Embodiment 1 Cloth cathode assembly preparation

[0041] A piece of commercially available canvas with a length, width and thickness of 14.5cm×17.5cm×0.6mm was used as the cloth base material, and the preparation steps of the cloth cathode group were as follows:

[0042] (1) Canvas waterproof and breathable treatment. Weigh 0.5g of polyvinylidene fluoride (PVDF) powder and dissolve it in 7.0mL of N-methylpyrrolidone, stir and mix and evenly paint on one side of the canvas, air-dry for 12 hours under natural conditions, and then dry at 80°C for 1 hours, the PVDF load on the canvas is calculated to be about 2.0mg / cm by weighing 2 ;

[0043] (2) Oxygen reduction catalyst and conductive paint mixed slurry preparation. Adopt commercially available electrolytic manganese dioxide (purchased from Xiangtan Electrochemical Group Co., Ltd.) as the oxygen reduction catalyst, nickel-based conductive paint (purchased from Wuxi Shuguang Paint Factory) as the conductive coating mate...

Embodiment 2

[0046] Embodiment 2 Fabric cathode assembly preparation

[0047] A piece of commercially available denim fabric with a length, width and thickness of 29cm×35cm×0.5mm is used as the cloth base material, and the preparation steps of the cloth cathode group are as follows:

[0048] (1) Denim waterproof and breathable treatment. Weigh 3.0g of polytetrafluoroethylene (PTFE) powder and dissolve it in 40.0mL of N-methylpyrrolidone, stir and mix and evenly paint on one side of the denim, air-dry for 10 hours under natural conditions, and then dry at 90°C After 1 hour, the PTFE load on the canvas is about 3.0mg / cm by weighing calculation 2 ;

[0049] (2) Oxygen reduction catalyst and conductive paint mixed slurry preparation. Commercially available tetramethoxyphenyl cobalt porphyrin (CoTMPP) (purchased from Beijing Bailingwei Chemical Technology Co., Ltd.) was used as the oxygen reduction catalyst, and graphite-based conductive paint (purchased from Wuxi Shuguang Paint Factory) was...

Embodiment 3

[0051] Embodiment 3 fabric cathode assembly preparation

[0052] A piece of commercially available canvas with a length, width and thickness of 14.5cm×17.5cm×0.6mm was used as the cloth base material, and the preparation steps of the cloth cathode group were as follows:

[0053] (1) Canvas waterproof and breathable treatment. Weigh 0.25g of polyvinylidene fluoride (PVDF) powder and dissolve it in 7.0mL of N-methylpyrrolidone, stir and mix, evenly paint on one side of the canvas, air-dry for 11 hours under natural conditions, and then dry at 50°C for 2 hours, the PVDF load on the canvas is calculated to be about 1.0mg / cm by weighing 2 ;

[0054] (2) Oxygen reduction catalyst and conductive paint mixed slurry preparation. Adopt commercially available electrolytic manganese dioxide (purchased from Xiangtan Electrochemical Group Co., Ltd.) as the oxygen reduction catalyst, nickel-based conductive paint (purchased from Wuxi Shuguang Paint Factory) as the conductive coating mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com