Method for separating and recycling materials of each component in waste printed circuit board

The technology of a printed circuit board and a recycling method is applied to the separation and recovery of each component material in waste printed circuit boards, and the field of waste printed circuit board recycling, which can solve the problems of one-sided resource recovery, high recovery cost, environmental pollution, etc. Achieve the effect of efficient separation and recycling, simple and feasible process, and good social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

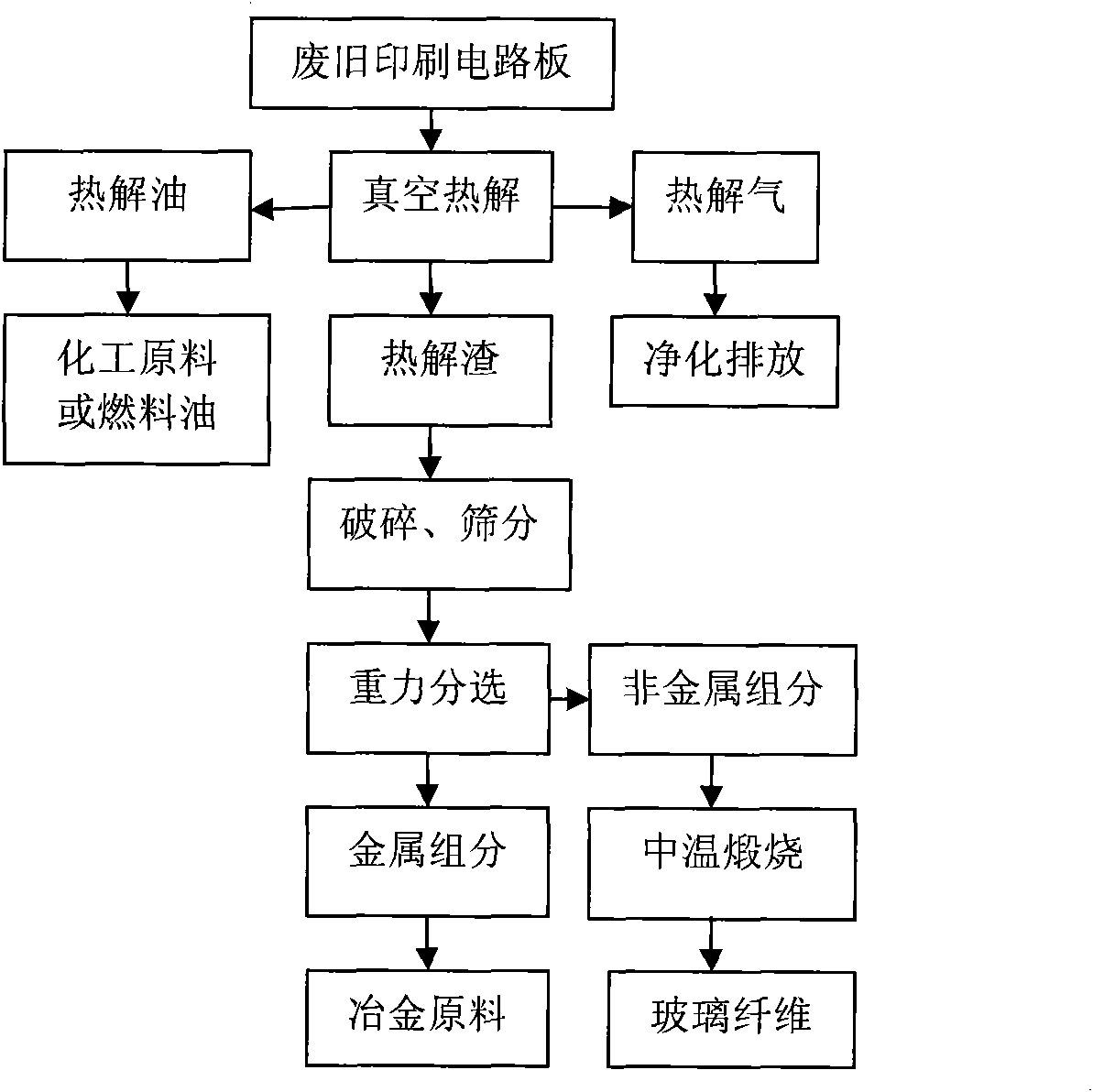

Image

Examples

Embodiment 1

[0021] a. Place a certain amount of waste printed circuit boards in the vacuum pyrolysis device, start the vacuum pump, reduce and maintain the pressure of the pyrolysis system at 1kPa, then heat to 350°C at a heating rate of 5°C / min and keep the temperature constant for 80min . The volatile gas produced by the vacuum pyrolysis process of organic matter is discharged through the exhaust pipe in the reactor of the vacuum pyrolysis device, and then the gas is condensed into liquid oil and non-condensable gas by the condenser of the vacuum pyrolysis device, and the non-condensable gas enters Gas collection and treatment system for purification treatment. Liquid oil is mainly composed of phenol, p-isopropylphenol, 2-bromophenol, 2,6-dibromophenol and other compounds, which can be used as fuel oil or chemical raw materials after purification. Non-condensable gas is mainly composed of hydrogen, carbon monoxide, carbon dioxide and lower alkanes, etc. It has a certain calorific value...

Embodiment 2

[0027] a. Place a certain amount of waste printed circuit boards in the vacuum pyrolysis device, start the vacuum pump, reduce and maintain the pressure of the pyrolysis system at 30kPa, then heat to 750°C at a heating rate of 25°C / min and keep the temperature constant for 20min . The volatile gas produced by the vacuum pyrolysis process of organic matter is discharged through the exhaust pipe in the reactor of the vacuum pyrolysis device, and then the gas is condensed into liquid oil and non-condensable gas by the condenser of the vacuum pyrolysis device, and the non-condensable gas enters Gas collection and treatment system for purification treatment. Liquid oil is mainly composed of phenol, p-isopropylphenol, 2-bromophenol, 2,6-dibromophenol and other compounds, which can be used as fuel oil or chemical raw materials after purification. Non-condensable gas is mainly composed of hydrogen, carbon monoxide, carbon dioxide and lower alkanes, etc. It has a certain calorific val...

Embodiment 3

[0033] a. Place a certain amount of waste printed circuit boards in the vacuum pyrolysis device, start the vacuum pump, reduce and maintain the pressure of the pyrolysis system at 15kPa, then heat to 550°C at a heating rate of 10°C / min and keep the temperature constant for 50min . The volatile gas produced by the vacuum pyrolysis process of organic matter is discharged through the exhaust pipe in the reactor of the vacuum pyrolysis device, and then the gas is condensed into liquid oil and non-condensable gas by the condenser of the vacuum pyrolysis device, and the non-condensable gas enters Gas collection and treatment system for purification treatment. Liquid oil is mainly composed of phenol, p-isopropylphenol, 2-bromophenol, 2,6-dibromophenol and other compounds, which can be used as fuel oil or chemical raw materials after purification. Non-condensable gas is mainly composed of hydrogen, carbon monoxide, carbon dioxide and lower alkanes, etc. It has a certain calorific val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com