Crystalline high polymer physical foaming material preparation method

A technology of physical foaming and high polymer, which is applied in the field of preparation of crystalline polymer physical foaming materials, can solve the problems of long cycle, unstable product quality and poor foamability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

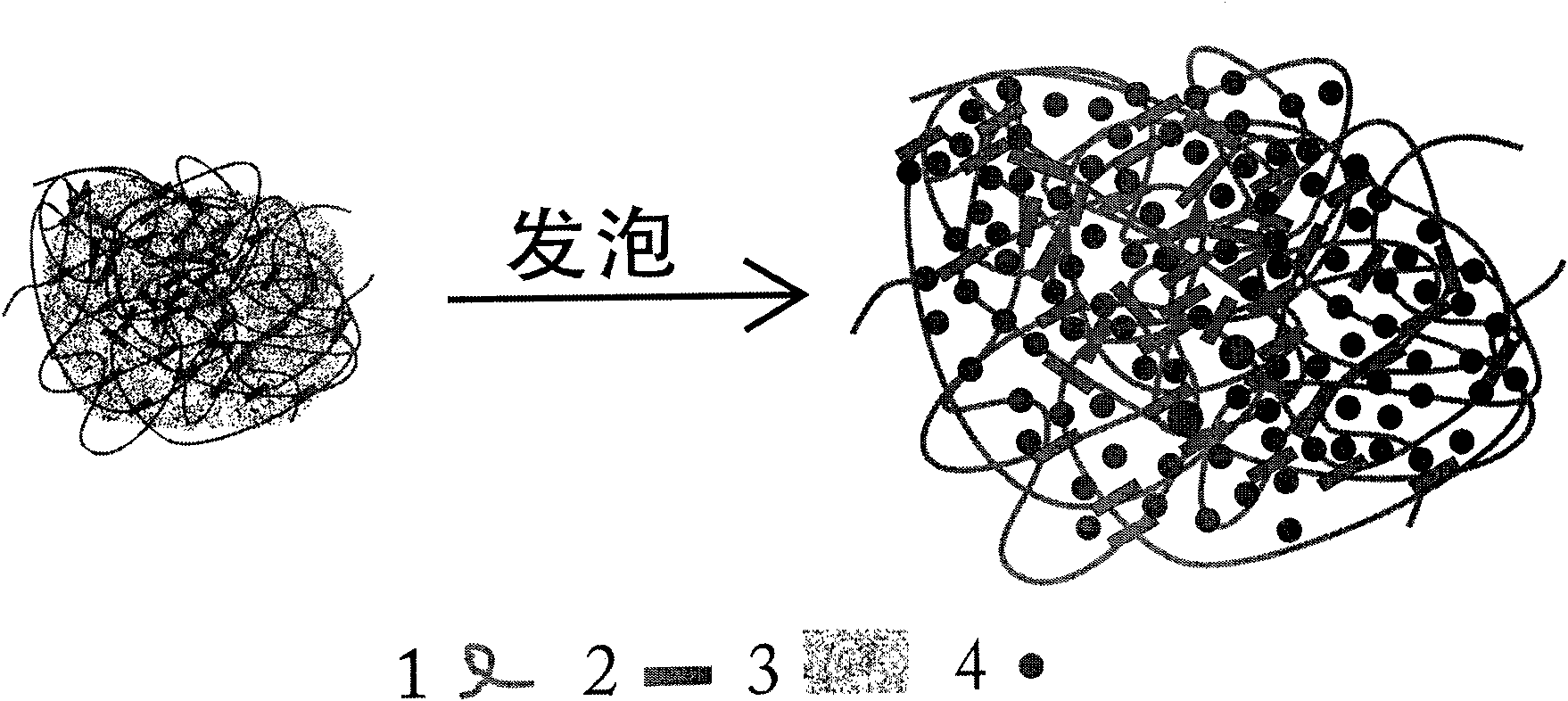

Method used

Image

Examples

Embodiment 1

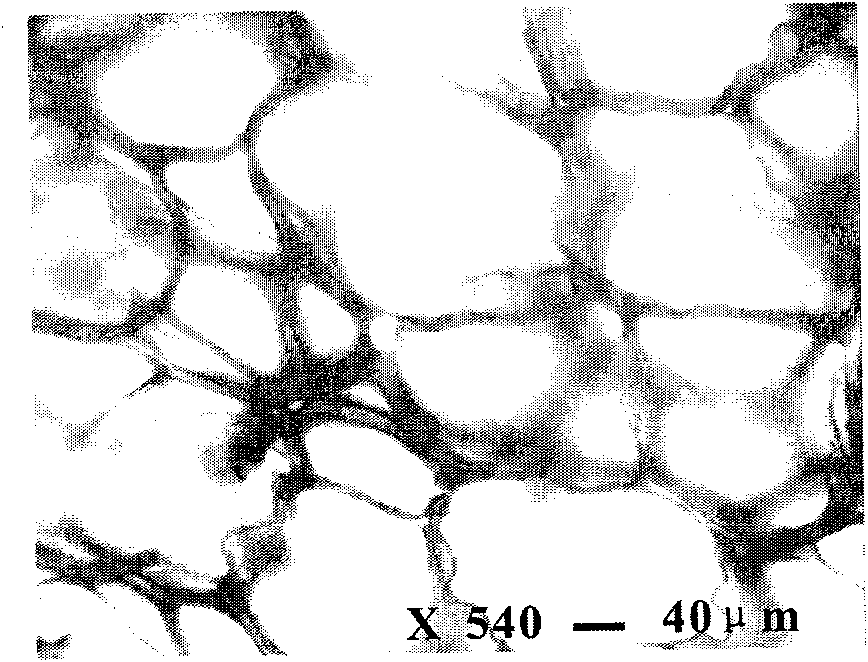

[0037] The physical gas foaming of embodiment 1 high-density polyethylene material

[0038] High-density polyethylene (6070EA, T m =131.5°C, T end =134.3°C) the particles are placed in a high temperature and high pressure resistant mold, ensuring that the total volume of the particles does not exceed 1 / 25 of the mold volume, so that the particles have enough space for foaming. The mold temperature is 132°C, 20MPa nitrogen gas is injected, the temperature is maintained at a constant pressure for 10 minutes, the pressure is released to normal pressure at a speed of 10MPa / s, the mold is opened, and the foaming material is taken out. The test foam material density is 0.22g / cm 3 , the average pore size is 127μm, and the expansion ratio is 4.4 times.

Embodiment 2

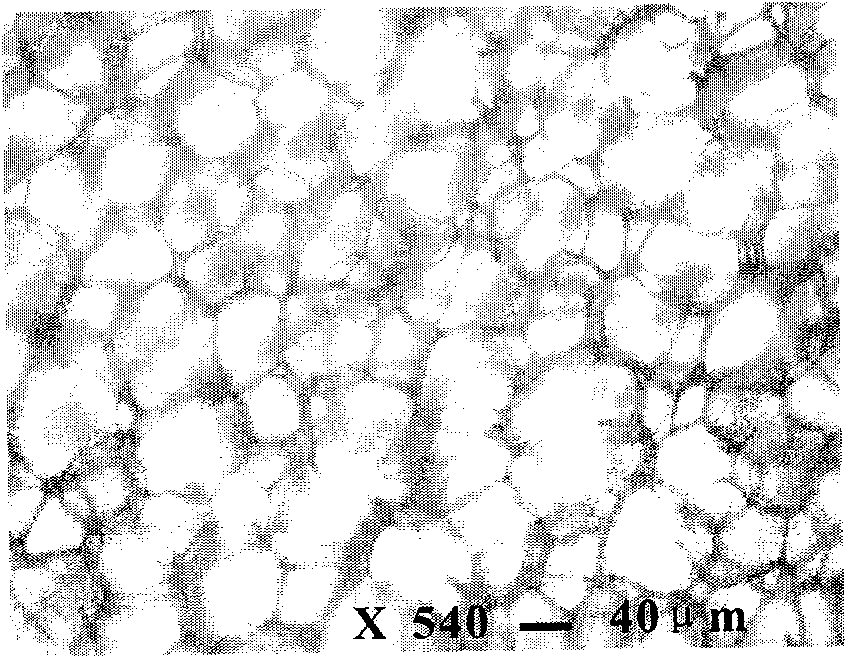

[0039] Embodiment 2 Physical gas foaming of polyadipate-terephthalate-butylene glycol ester

[0040] Polybutylene adipate-terephthalate (PBAT, T m =128.4°C, T end =143.1°C) the particles are placed in a high temperature and high pressure resistant mold, ensuring that the total volume of the particles does not exceed 1 / 25 of the mold volume, so that the particles have enough space for foaming. The mold temperature is 138°C, 8MPa nitrogen gas is injected, the temperature is maintained at a constant pressure for 10 minutes, the pressure is released to normal pressure at a speed of 5MPa / s, the mold is opened, and the foaming material is taken out. The test foam material density is 0.20g / cm 3 , the average pore size is 250μm, and the expansion ratio is 5.8 times.

Embodiment 3

[0041] The physical gas foaming of embodiment 3 low density polyethylene material

[0042] 1) Low-density polyethylene (IF7B, T m =104.4°C, T end =110.0°C) the particles are placed in a mold resistant to high temperature and high pressure, ensuring that the total volume of the particles does not exceed 1 / 25 of the mold volume, so that the particles have enough space for foaming. The mold temperature is 108°C, 20MPa nitrogen is injected, the temperature is maintained at a constant pressure for 30 minutes, the pressure is released to normal pressure at a speed of 10MPa / s, the mold is opened, and the foaming material is taken out. The test foam material density is 0.077g / cm 3 , the average pore size is 161 μm, and the expansion ratio is 12.1 times.

[0043] 2) Low-density polyethylene / ethylene propylene block copolymer (90 / 10) blend material (K8303, Tm=164.3°C, T end =168.6°C), prepared by the MiniLab micro-blending rheometer of HAAKE Company. The melting temperature is 190°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com