Continuous leather staining method by ultrasonic wave and microwave radiation

A technology of microwave radiation and dyeing method, which is applied in the field of leather dyeing, can solve the problems that dyes are difficult to penetrate deeply and distribute uniformly, and cannot meet the basic requirements of dyeing of high-quality leather dyes, and achieve the effect of ingenious conception, simple process and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

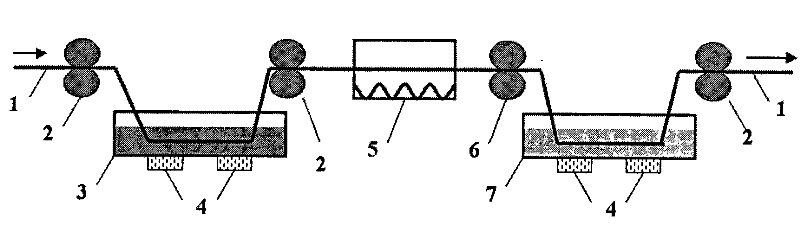

Method used

Image

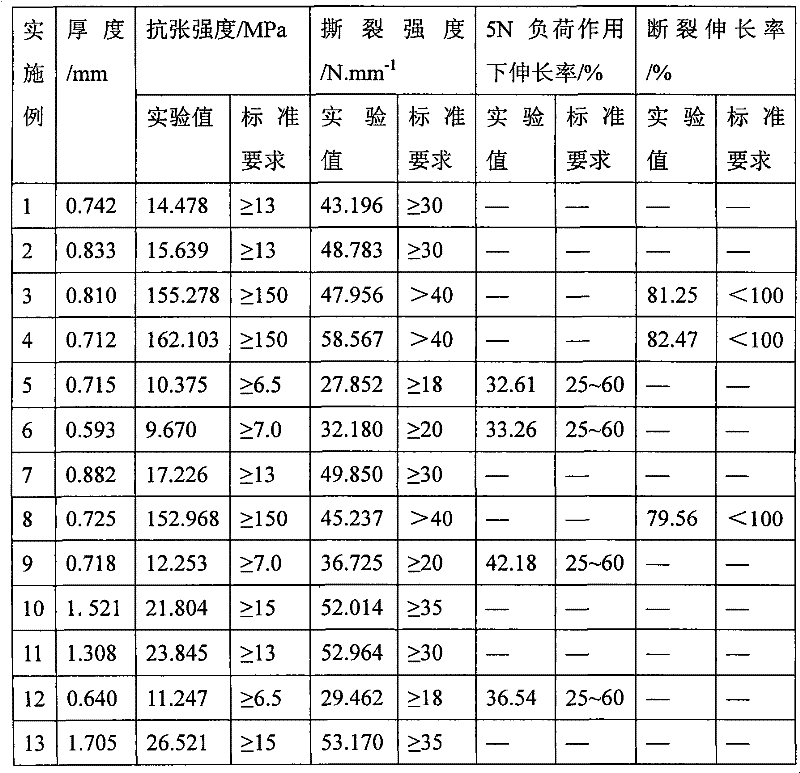

Examples

Embodiment 1

[0026] After retanning with chrome tanning agent, sulfated castor oil and polymer fatliquor, the wet sheep leather shoe upper leather with a thickness of 1.4mm is first mechanically extruded to a moisture content of 50-55%, and then ultrasonically The frequency is 20kHz and the radiation intensity is 0.5W / cm 2 , dyed in a dyeing bath solution at 25°C containing 4% penetrating black and 0.5% polysiloxane wetting agent for 1 min; mechanically extruded the dyed leather until the content of the dye solution was 60-65%, and the frequency of use was 2450MHz, radiation intensity of 1W / cm 3 Microwave irradiation for 1min; the dyed leather after microwave irradiation is at an ultrasonic frequency of 20kHz and a radiation intensity of 0.5W / cm 2 , fix the color in a 1% aluminum chloride solution at a temperature of 25°C for 3 minutes; mechanically squeeze the dyed leather that has been fixed until the content of the fixing solution is 60-65%, and then proceed according to the convention...

Embodiment 2

[0028] After retanning with amino resin retanning agent, sulphated ox hoof oil and lecithin fatliquoring agent, the wet goatskin shoe upper leather with a thickness of 1.6mm is first mechanically extruded to a moisture content of 45-50%, and then At an ultrasonic frequency of 40kHz and a radiation intensity of 1.5W / cm 2 , dyed in a dyeing bath solution containing 0.5% reactive yellow and 0.2% alkylphenol ether sulfosuccinate sodium at a temperature of 45°C for 2 minutes; mechanically extruded the dyed leather until the content of the dye solution was 50-55%, and then used The frequency is 2450MHz, and the radiation intensity is 0.1W / cm 3 Microwave irradiation for 3min. Then, dry and paint and other treatments can be carried out according to the conventional follow-up procedures. The extruded dye solution returns to the system.

Embodiment 3

[0030] Retanned with chrome tanning agent and acrylic resin retanning agent, fatliquored with synthetic hoof oil fatliquor, the wet pigskin shoe lining leather with a thickness of 1.6mm is first mechanically extruded to a moisture content of 55-60%, and then Ultrasonic frequency is 70kHz, radiation intensity is 3W / cm 2 , Dyeing in a dyeing bath solution containing 1% reactive red and 1% sodium polysuccinate sulfonate at a temperature of 40°C for 3 minutes; mechanically squeeze the dyed leather until the content of the dye solution is 65-70%, and use a frequency of 2450MHz , Radiation intensity is 3W / cm 3 Microwave irradiation for 1min; the dyed leather after microwave irradiation is at an ultrasonic frequency of 70kHz and a radiation intensity of 3W / cm 2 , the temperature is 40 ℃, the concentration is 1% aluminum trichloride and aluminum sulfate (mass ratio is 1: 1) solution 1min; The dyed leather mechanically extruded to fix color is 65 After ~70%, it is enough to carry out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com