PVC homogeneous penetrating coiled material floor, preparation method and device thereof

A coiled flooring, homogeneous and transparent technology, applied in coating, layered products, construction, etc., can solve the problem of high cost, achieve good wear resistance, good social and economic value, and good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

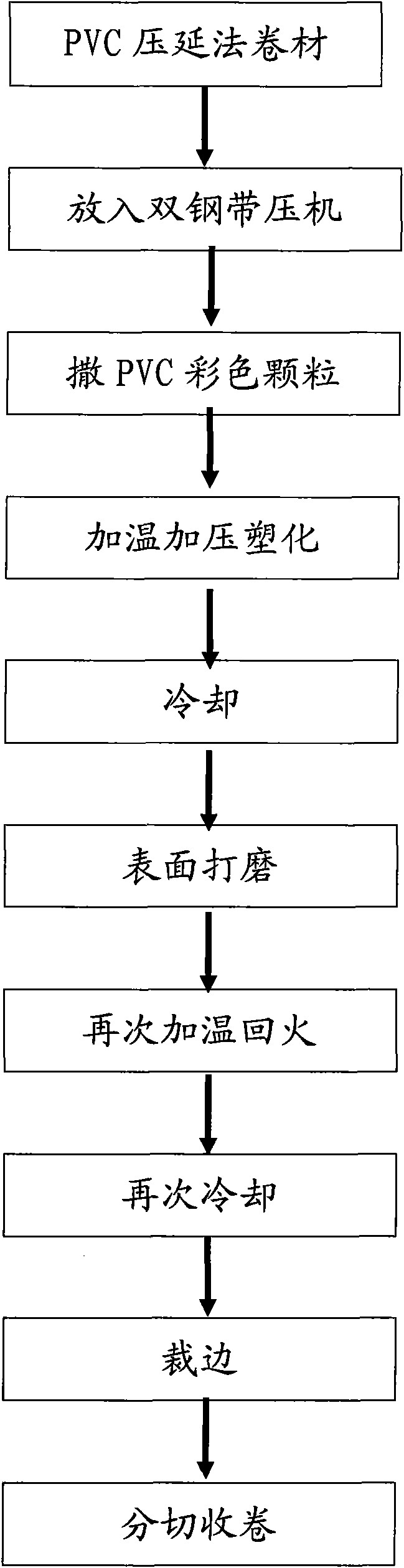

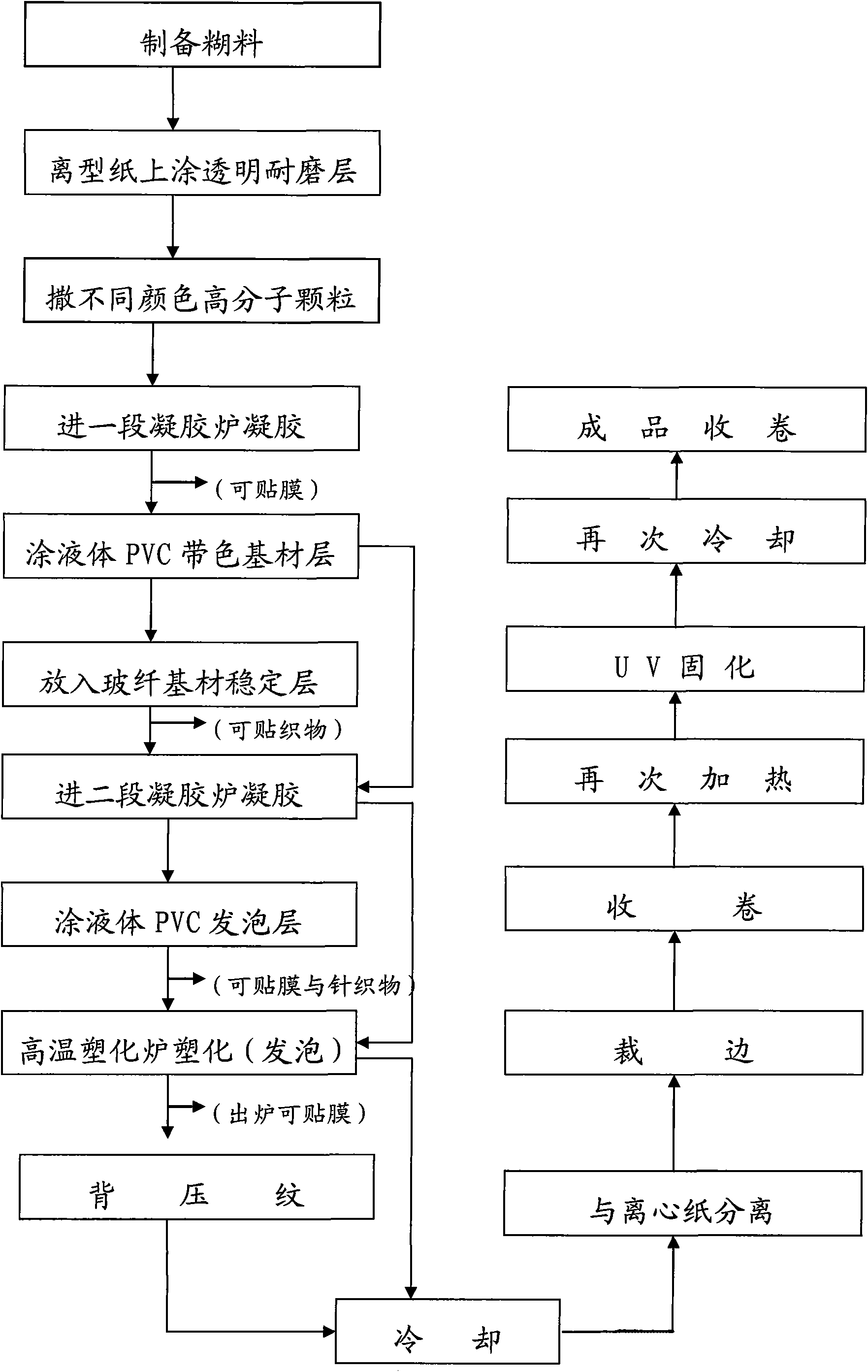

[0038] A kind of preparation method of PVC homogeneous permeable coiled material floor, its process see figure 2 shown, including the following steps:

[0039] (1) First coating: roll the release paper on the release paper discharge rack 201, and guide it into the floor production line by the pulling roller, first enter the first section of the coating machine 203, and apply the PVC transparent paste Coated on the release paper to form a transparent wear-resistant layer, the thickness is controlled between 0.05-0.8mm;

[0040] (2) Spreading flowers: Use a flower spreading machine to randomly sprinkle plastic particles on the PVC transparent paste;

[0041] (3) Primary gel cooling: the plastic particles are coagulated on the wear-resistant layer through the first 10-meter gel furnace 204, the gel temperature is 180-190°C, and the gel time is 0.5-2 minutes; After the product comes out of the gel furnace 204, it is cooled to 5°C-25°C by the cooling wheel 206;

[0042] (4) Secon...

Embodiment 2

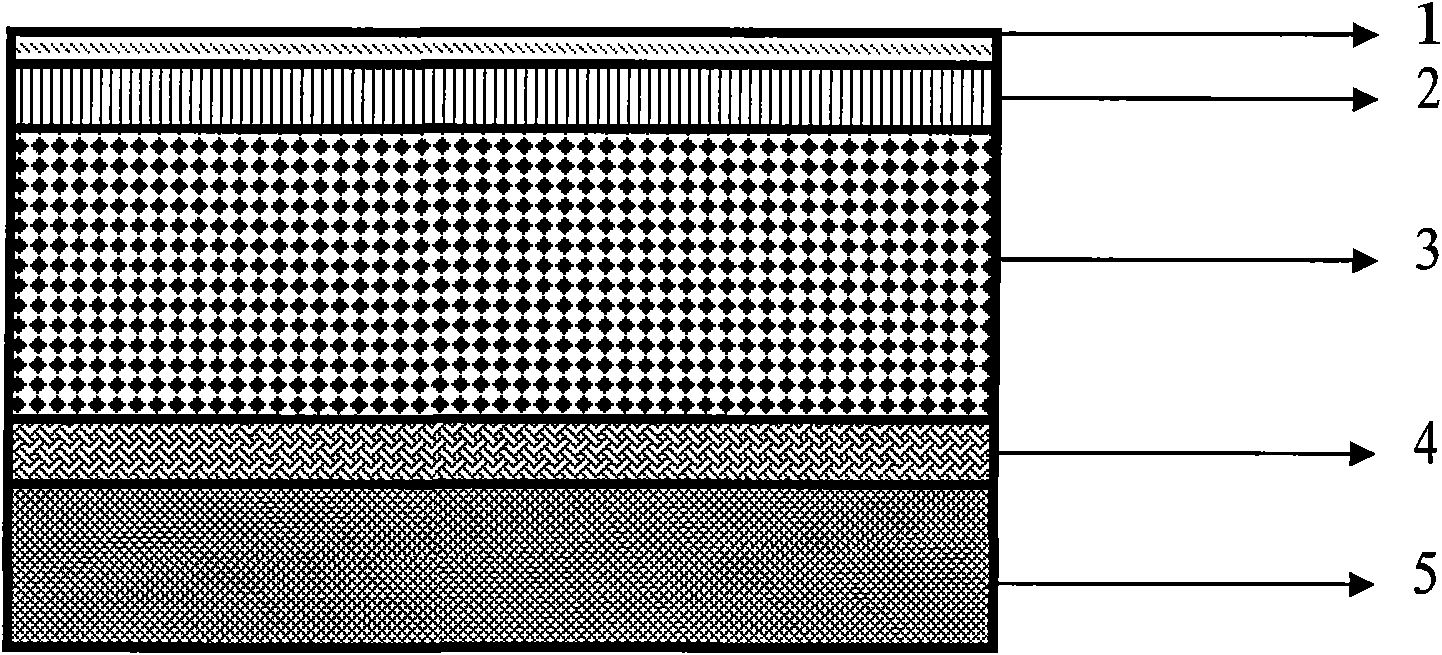

[0051] A new type of PVC homogeneous transparent coil floor, see image 3 As shown, it includes a five-layer structure, from top to bottom, UV curing layer 1, wear-resistant transparent layer 2, PVC colored substrate layer 3 embedded with colored plastic particles, stable layer 4 and elastic foam layer 5. The thickness of the UV curable layer 1 is 0.01-0.1mm, the thickness of the wear-resistant transparent layer 2 is 0.05-0.8mm, the thickness of the PVC colored substrate layer 3 is 0.5-2mm, and the thickness of the elastic foam layer 5 is 1-5mm , the overall thickness of the floor is 1.0-10mm, and the width is 1.5-2m. The UV treatment layer 1 is the treatment layer formed after the UV coating applied on the floor surface is irradiated with three 19 kilowatt ultraviolet lamps for 20-30 seconds at a temperature of 60°C-80°C and cured; the wear-resistant transparent layer 2 is PVC transparent The paste is formed by applying gel, and the PVC colored base material layer 3 embedded...

Embodiment 3

[0053] A device for producing the above-mentioned PVC homogeneous core-permeable coil floor, see Figure 4 As shown, according to the production sequence, a release paper discharge rack 201, a pulling frame 202, a first-stage coater 203, a first-stage gel furnace 204, a first-stage cooling wheel 205, a second-stage coater 206, Two-stage gel furnace 207, two-stage cooling wheel 210, three-stage coating machine 211, PVC foam material discharge rack 212, three-stage high-temperature plasticizing furnace 213, three-stage cooling turbine 215, trimming machine 216 and coiling Machine 220 pulls the release paper through the power device and control system along the above-mentioned order; wherein, an automatic flower spreading machine is set before the first gel oven 204, after the first gel oven 205, before the second gel oven 207 and A discharge rack (205,208,214) is all added behind the three-section high-temperature plasticizing furnace 213. After the trimming machine 217, a rele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com