Method for testing polarity of semiconductor crystal or epitaxial thin film material and test system

A technology for epitaxial thin films and semiconductors, which is applied in the fields of analyzing materials, using wave/particle radiation for material analysis, and measuring devices, etc. It can solve the problems of demanding sample surface cleanliness, difficulty in sample preparation and instrument operation, and low accuracy. To achieve the effect of simple and fast sample preparation, lower test costs, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

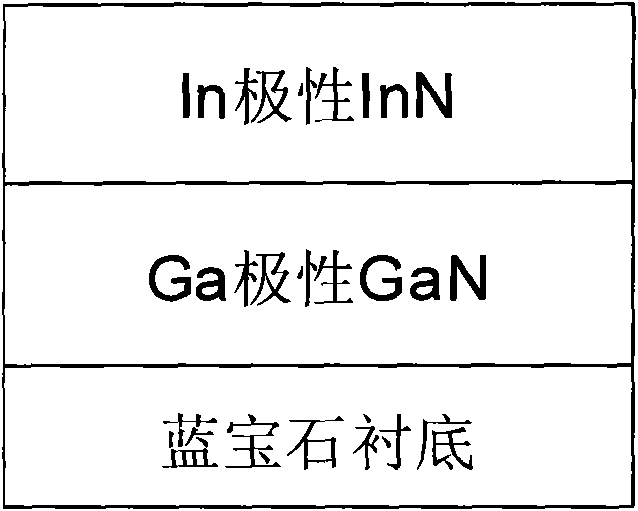

[0018] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

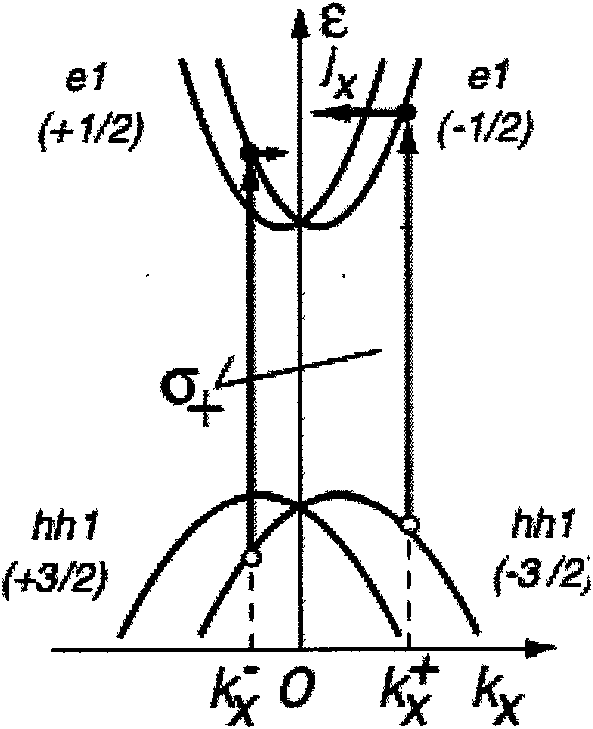

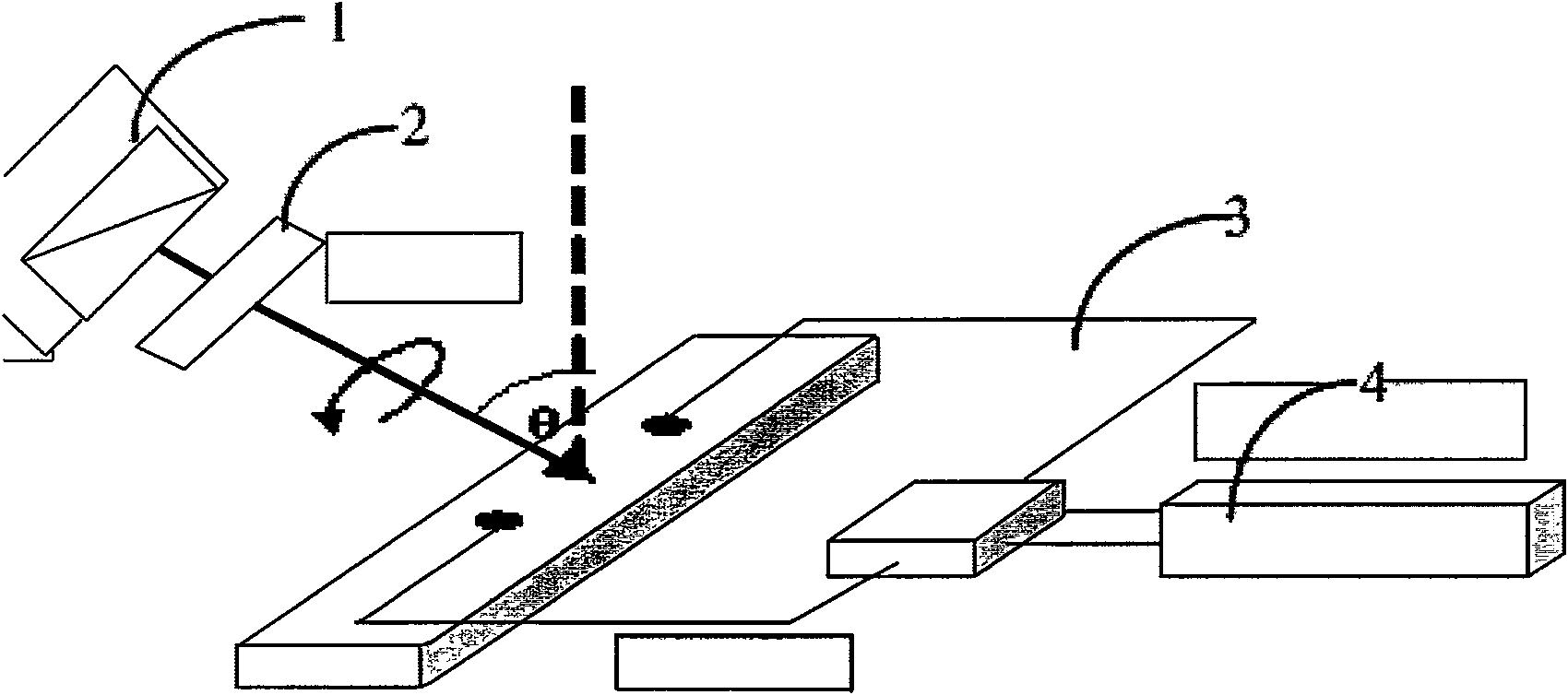

[0019] The invention utilizes the circular photo-galvanic effect (CPGE, circular photo-galvanic effect) to judge the polarity of the semiconductor crystal or the epitaxial thin film. Circularly polarized spin photoelectric effect means that in semiconductor crystals or semiconductor low-dimensional structures lacking spatial inversion symmetry, a weak unbiased directional current will be formed by circularly polarized light irradiation, and the magnitude of the current changes with the helicity of the incident light. The currents generated by left and right circularly polarized light are equivalent and reversed. It is worth emphasizing that only semiconductor materials la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com