Overlaying layer stripping ultrasound detection imaging system of major-diameter thick-wall pressure vessel

A technology of pressure vessel and imaging system, which is applied in the direction of using sound wave/ultrasonic wave/infrasonic wave to analyze solids and process detection response signals. Problems such as cracks and the expansion of the interlayer peeling area of the surfacing layer, etc., achieve the effect of rapid evaluation of detection data, convenient on-site engineering application, and avoiding low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

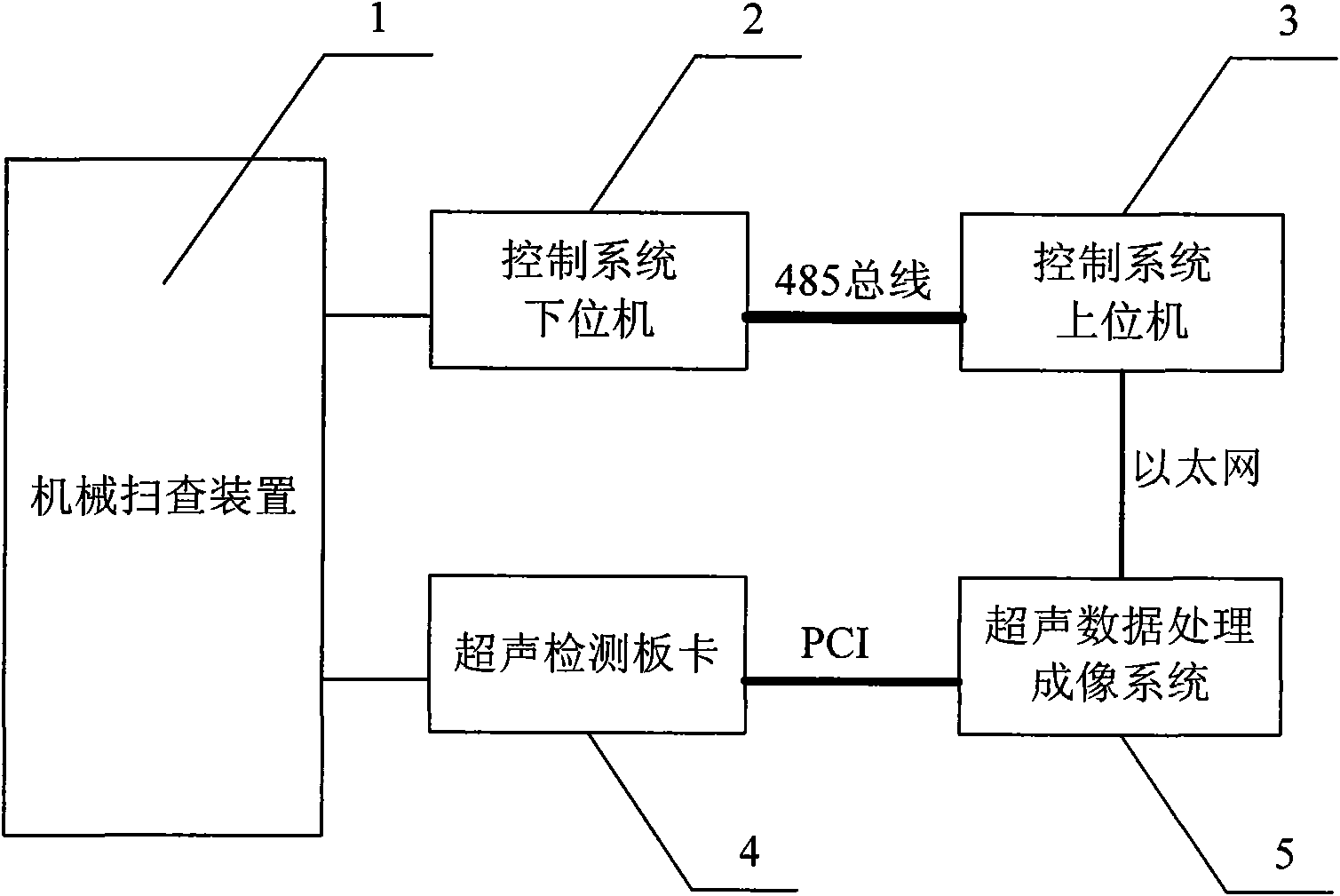

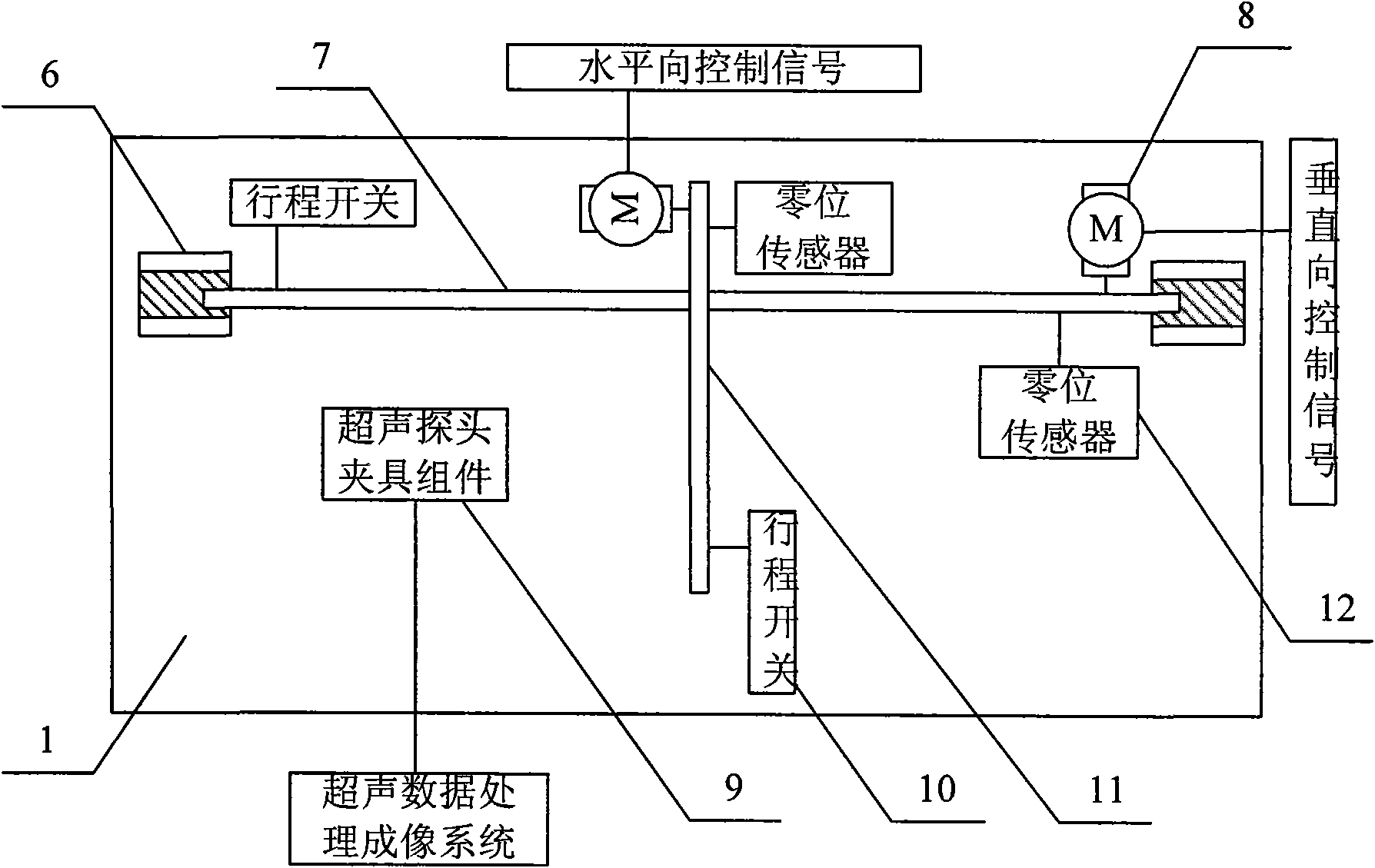

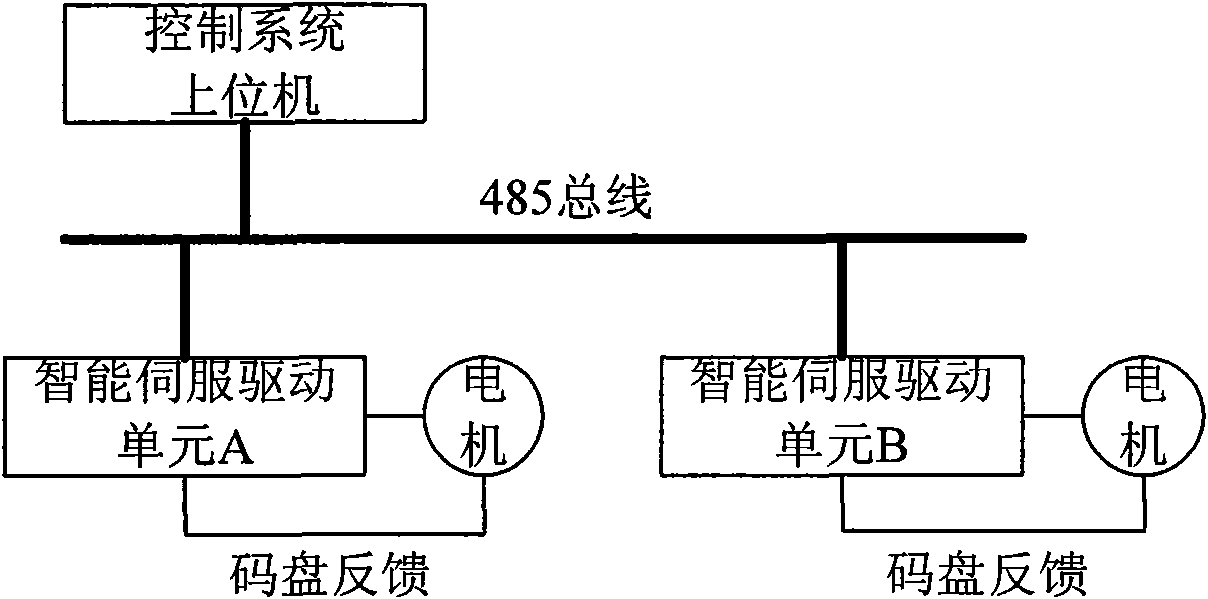

[0022] like figure 1 As shown, a large-diameter thick-wall pressure vessel surfacing layer peeling ultrasonic detection imaging system, which includes a mechanical scanning device 1, an ultrasonic detection board 4, an ultrasonic data processing imaging system 5, and a control system upper and lower computer 3, 2 components . Among them, the upper computer 3 of the control system and the lower computer 2 are connected in a distributed manner using the 485 bus, and all control commands and signal data of the upper computer 3 of the control system interact with the lower computer 2 of the control system through the 485 bus to realize system functions; the ultrasonic probe fixture Components (9) (such as figure 2 As shown) the data collected by the probe is transmitted to the ultrasonic detection board 4 of the imaging processing system 5 for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com