A kind of preparation method of coating

A coating and raw material technology, which is applied to the preparation of coatings by using pyrite slag, can solve the problems of high cost, large resources and energy consumption, and achieve low cost, high comprehensive utilization of resources and wide sources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

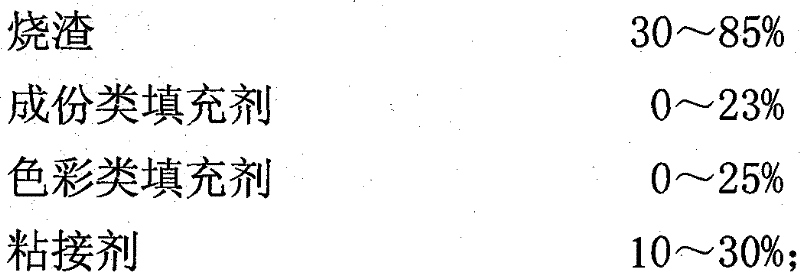

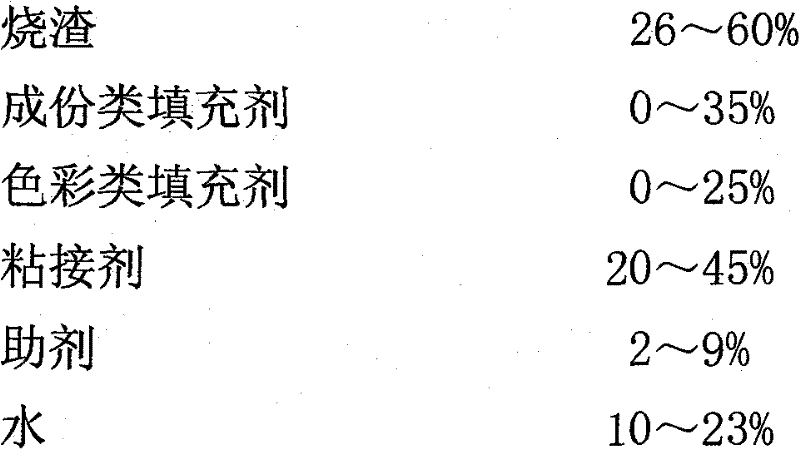

Method used

Image

Examples

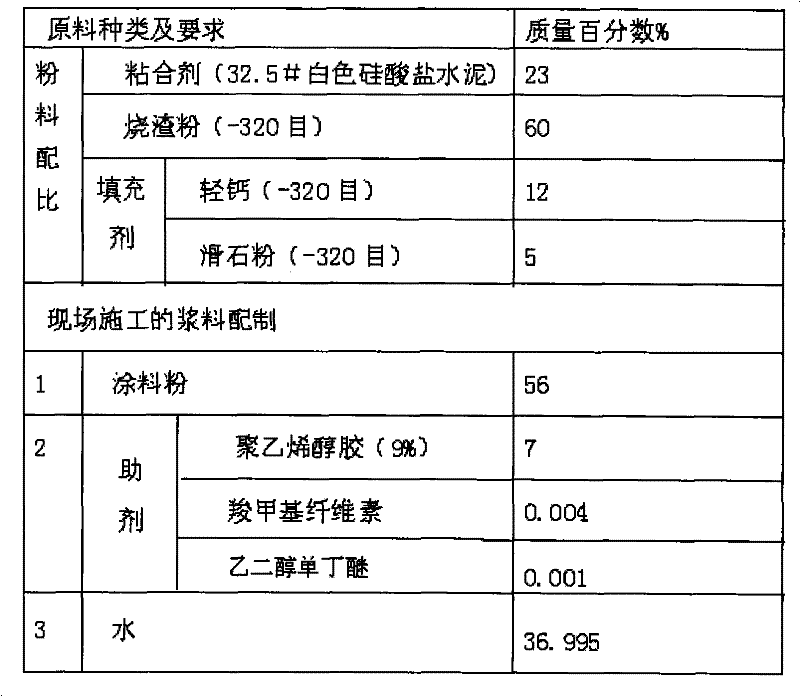

Embodiment 1

[0045] The pyrite (containing S: 19%) mined by Yunnan Weixin is crushed into fine particles less than 4mm, and then naturally stacked and dried to obtain dry materials with a water content of less than 6% for later use; the above dried materials are added to a conventional fluidized furnace, Carry out conventional boiling desulfurization at a temperature of 850-950°C to obtain slag; add white Portland cement binder to the slag, and add light calcium carbonate and talcum powder as auxiliary fillers to grind to -320 To obtain red powder coating. During on-site construction, add water, polyvinyl alcohol additives, toughening and leveling agents, etc. into the powder coating, stir evenly, and adjust it to a fluid coating with a certain viscosity. The coating can be applied not only on dry cement walls, but also on wet walls that have just been constructed but have initially hardened. The coating has good adhesion, hardness and scrubbing resistance, and is environmentally friendly....

Embodiment 2

[0048] The raw material of pyrite (containing S: 16%) mined in Hulong, Gulin, Sichuan, was crushed into fine particles smaller than 4mm, and then naturally stacked and dried to obtain materials with a water content of less than 6% for use; the above materials were added to conventional In the boiling furnace, at a temperature of 900-980°C, conventional boiling roasting desulfurization is carried out to obtain slag, and the slag is crushed to 0.5mm-0.1mm fine powder, and the magnetic field strength is 2000-12000GS. The magnetic separator performs dry magnetic separation to make the Fe in the slag 2 o 3 The content is less than 4%, and the main component of the slag after selection is amorphous Al formed after kaolinite is calcined and decomposed. 2 o 3 and SiO 2 , anatase TiO 2 and a small amount of Fe 2 o 3 and Fe(OH) 3 , add a small amount of light calcium carbonate, talc powder, sericite powder auxiliary filler to this slag, then add lead chrome yellow color filler, g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com