Kieselguhr wall material, preparation technology and construction technology thereof

A diatomite and wall material technology, applied in silicon compounds, inorganic chemistry, construction, etc., can solve problems such as pollution, furniture cracking, deformation, moldy, and deterioration of decorative materials, so as to improve the indoor environment, reduce pet odor, and prevent The effect of sticking dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A diatomite wall material, comprising the following components by weight: 25 parts of diatomite, 15 parts of micro-nano tourmaline, 5 parts of nano-scale titanium dioxide, 11 parts of nano-scale zinc oxide, and 18 parts of inorganic gel powder , 38 parts of silica sand.

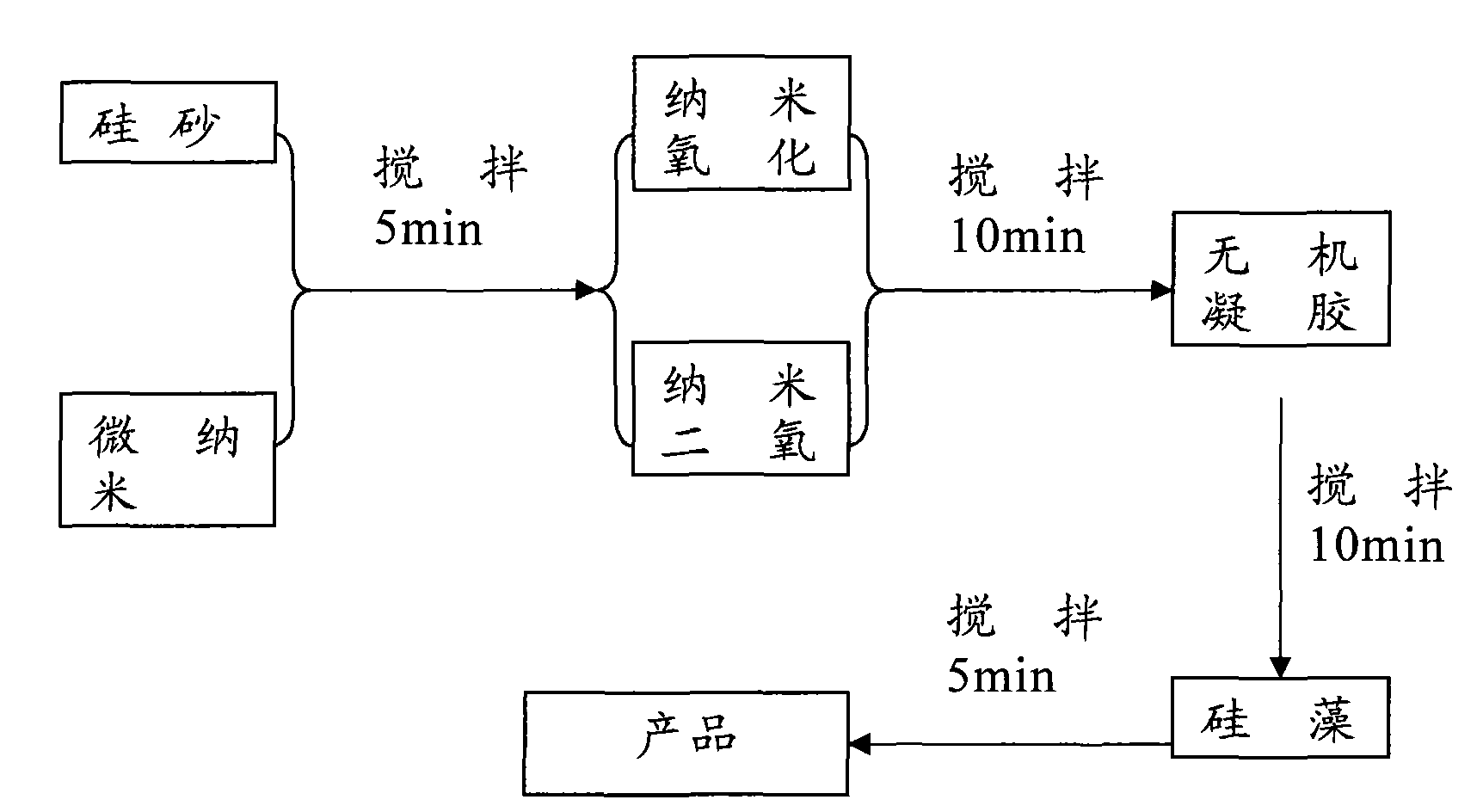

[0029] Weigh the above-mentioned components separately, such as figure 1 The preparation process shown is to mix silica sand and micro-nano tourmaline for 5 minutes, then add nano-zinc oxide and nano-titanium dioxide, stir for 10 minutes until uniform, then add inorganic gel powder, stir for 10 minutes and then add silicon All raw materials are mixed and stirred for 5 minutes with diatomaceous earth and pigments in appropriate proportions, and the raw materials of diatomite wall material are obtained.

Embodiment 2

[0031] A diatomite wall material, comprising the following components in parts by weight: containing SiO 2 35 parts of diatomite with a weight percent content of 90%, 10 parts of tourmaline with a particle diameter of 4 microns, 10 parts of titanium dioxide with a particle diameter of 10 nanometers, 6 parts of zinc oxide with a particle diameter of 10 nanometers, 6 parts of zinc oxide with a particle diameter of 325 The purpose is 25 parts of inorganic gel powder and 28 parts of silica sand with a particle size of 100 mesh.

[0032] The preparation process is the same as in Example 1.

Embodiment 3

[0034] A diatomite wall material, comprising the following components in parts by weight: containing SiO 2 30 parts of diatomite with a weight percent content of 92%, 12 parts of tourmaline with a particle diameter of 14 microns, 8 parts of titanium dioxide with a particle diameter of 10 nanometers, 9 parts of zinc oxide with a particle diameter of 10 nanometers, 9 parts of zinc oxide with a particle diameter of 325 The objective is 21 parts of inorganic gel powder and 32 parts of silica sand with a particle size of 70 mesh.

[0035] The preparation process is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com