High tenacity low smoke zero halogen flame retardant polypropylene and preparation method thereof

A flame-retardant polypropylene and high-toughness technology, applied in the field of low-smoke halogen-free flame-retardant polypropylene and its preparation, can solve the problem of poor environmental protection performance and smoke suppression performance, unable to solve the problem of smoke suppression performance, poor processing performance of tougheners, etc. problem, to achieve good smoke suppression performance, low cost and good processing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

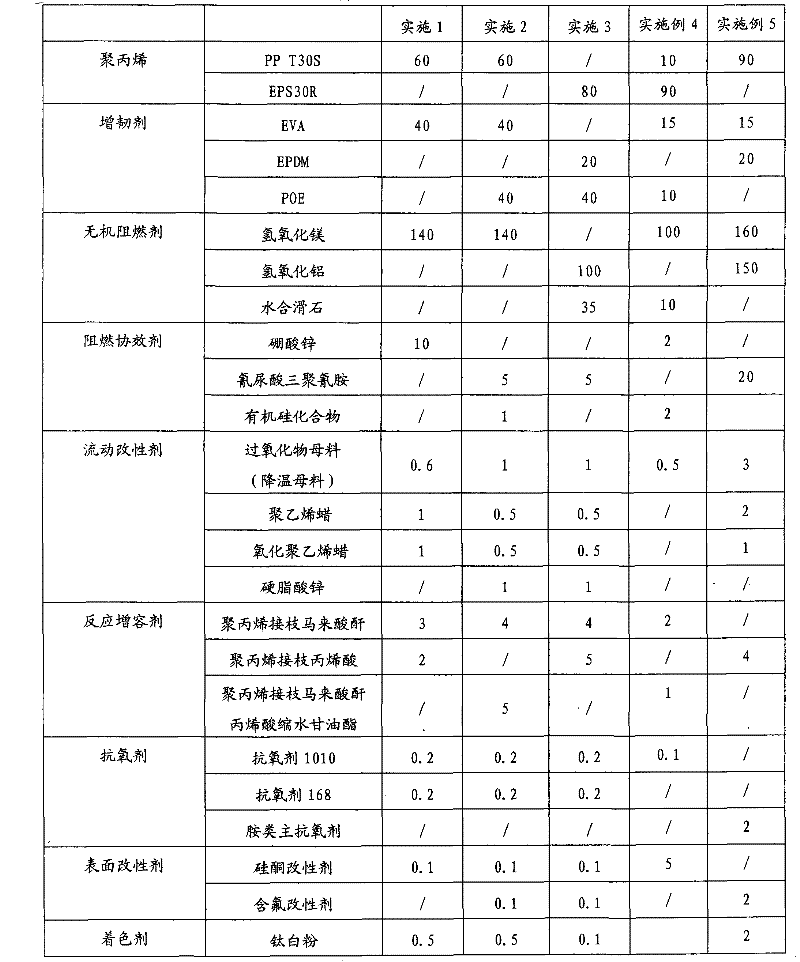

[0029] The present invention proposes a low-smoke, halogen-free and phosphorus-free flame-retardant polypropylene with high toughness and a preparation method thereof. The materials used in it include: polypropylene, toughening agent, inorganic flame retardant, flame retardant synergist, and reaction enhancement Composting agent, antioxidant, flow modifier, surface modifier, proper amount of coloring agent.

[0030] The polypropylene is homopolypropylene (PP T30S) or copolymer polypropylene (EPS30R) and blends thereof, and its melt flow rate is 0.1-30 g / 10min.

[0031] The toughening agent is ethylene propylene rubber (EPDM), ethylene propylene rubber, ethylene-vinyl acetate copolymer (EVA), polyolefin elastomer (ethylene-octene copolymer / POE) and other polypropylene toughening One or more of the agents. To improve the toughness of PP, its role is to induce crazing and shear bands to make the matrix yield and absorb a large amount of energy, thereby improving the toughness of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com