Reaction kettle for direct coal liquefaction and application thereof

A technology of direct coal liquefaction and reaction kettle, which is used in the preparation of liquid hydrocarbon mixtures and the petroleum industry, etc., can solve the problems of easy coking on the inner wall, low gas content, shortened material residence time, etc., to eliminate local thermal effects, gas content Uniform rate distribution and improved solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

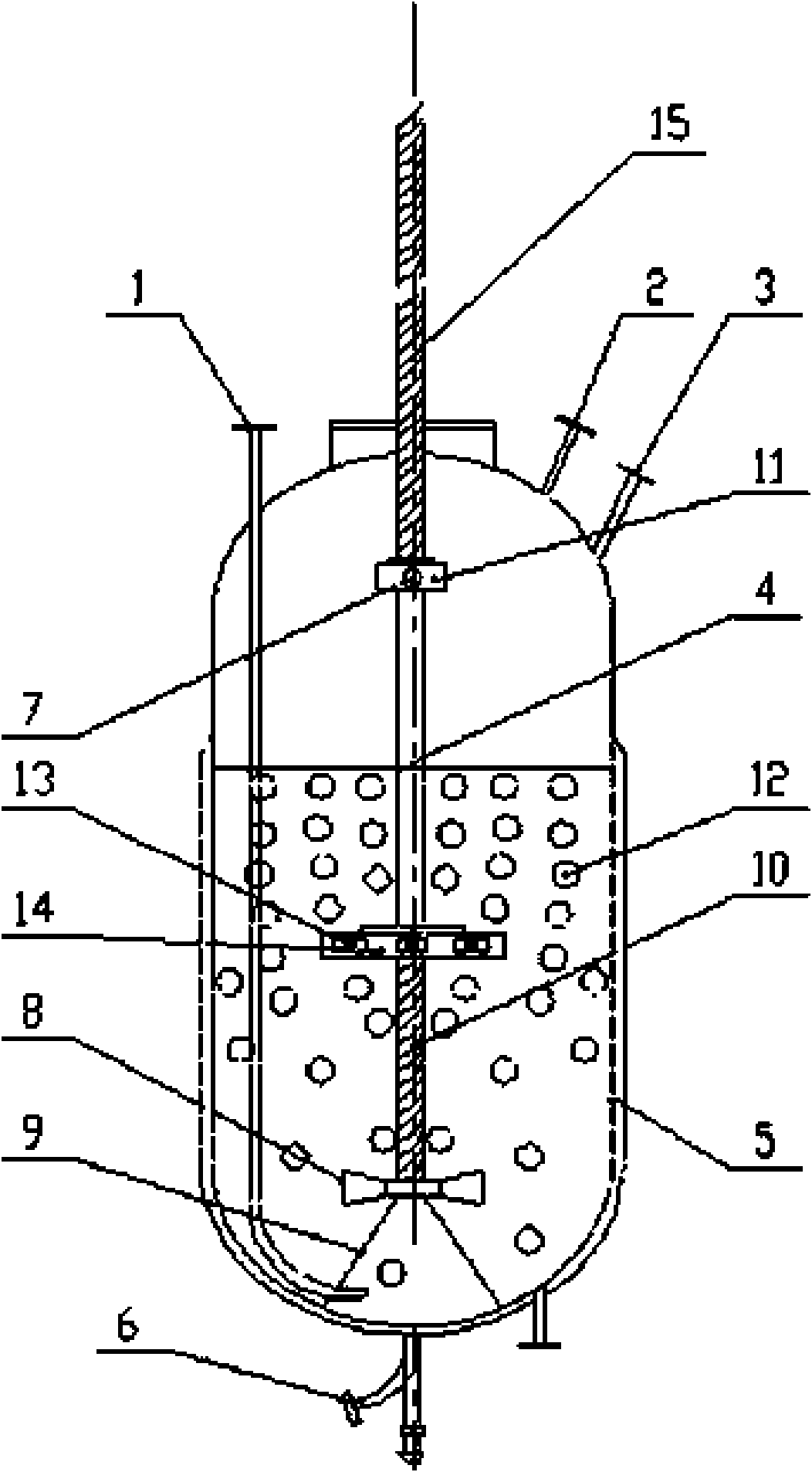

[0049] 150g particle size is less than the lignite powder that 160 order Inner Mongolia produces, 300g tetrahydronaphthalene are mixed homogeneously (the weight portion ratio of the two is 35: 70), obtain slurry mixture; The material inlet 2 of described slurry mixture from reactor Pump into the reaction kettle provided by the present invention with an inner volume of 1000ml. After nitrogen replacement in the reaction kettle, fill hydrogen into the reaction kettle body 5 from the suction pipe 1 of the reaction kettle. The initial pressure of hydrogen is 5MPa, open The stirrer of the reaction kettle was used to raise the reaction temperature to 400°C and react for 60 minutes. Wherein the stirring speed of the stirrer in the reaction kettle is 800rpm. After the reaction, the liquid-solid product is discharged from the material outlet 6 at the bottom of the reactor, and the gas is discharged from the gas outlet 3 at the upper part of the reactor.

[0050] Product separation: Aft...

Embodiment 2

[0061] Mix 150g of lignite powder and 350g of hydrogenated anthracene oil with a particle size less than 200 meshes evenly (the weight ratio of the two is 40:93.3) to obtain a slurry mixture; the slurry mixture is imported from the reactor 2 pump into the reaction kettle provided by the present invention with an inner volume of 1000ml, after nitrogen replacement in the reaction kettle, fill hydrogen into the reaction kettle body 5 from the suction pipe 1 of the reaction kettle, the initial pressure of hydrogen is 2MPa, Turn on the stirrer of the reaction kettle, raise the reaction temperature to 420° C., and react for 80 minutes. Wherein the stirring speed of the stirrer in the reaction kettle is 800rpm. After the reaction, the liquid-solid product is discharged from the material outlet 6 at the bottom of the reactor, and the gas is discharged from the gas outlet 3 at the upper part of the reactor.

[0062] The separation method of the product, the calculation method of the c...

Embodiment 3

[0065]Mix 150g of bituminous coal powder and 150g of catalytic cracking residual oil with particle size less than 160 orders in Shanxi (the weight ratio of the two is 50:50) to obtain a slurry mixture; Inlet 2 is pumped into the reaction kettle provided by the invention with an inner volume of 1000ml. After nitrogen replacement in the reaction kettle, hydrogen is charged from the suction pipe 1 of the reaction kettle into the reaction kettle body 5. The initial pressure of hydrogen is 7MPa , turn on the stirrer of the reaction kettle, raise the reaction temperature to 450° C., and react for 70 minutes. Wherein the stirring speed of the stirrer in the reaction kettle is 800rpm. After the reaction, the liquid-solid product is discharged from the material outlet 6 at the bottom of the reactor, and the gas is discharged from the gas outlet 3 at the upper part of the reactor.

[0066] The separation method of the product, the calculation method of the coal conversion rate and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com