Test structure for measuring thermal conductivity of film

A technology for testing structures and thin films, applied in the field of microelectronics, can solve the problems of complex manufacturing process and test structure, inconvenient measurement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the drawings:

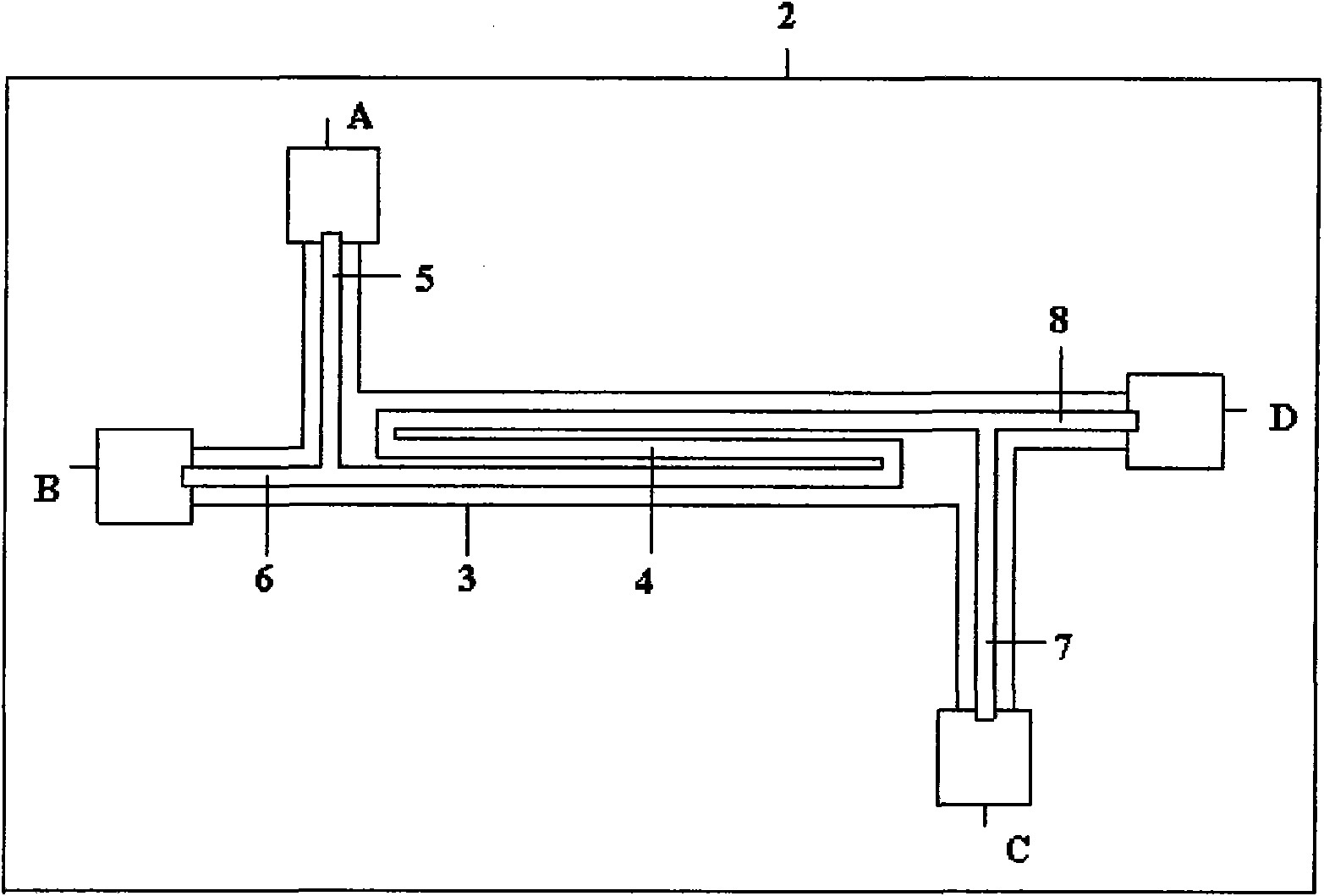

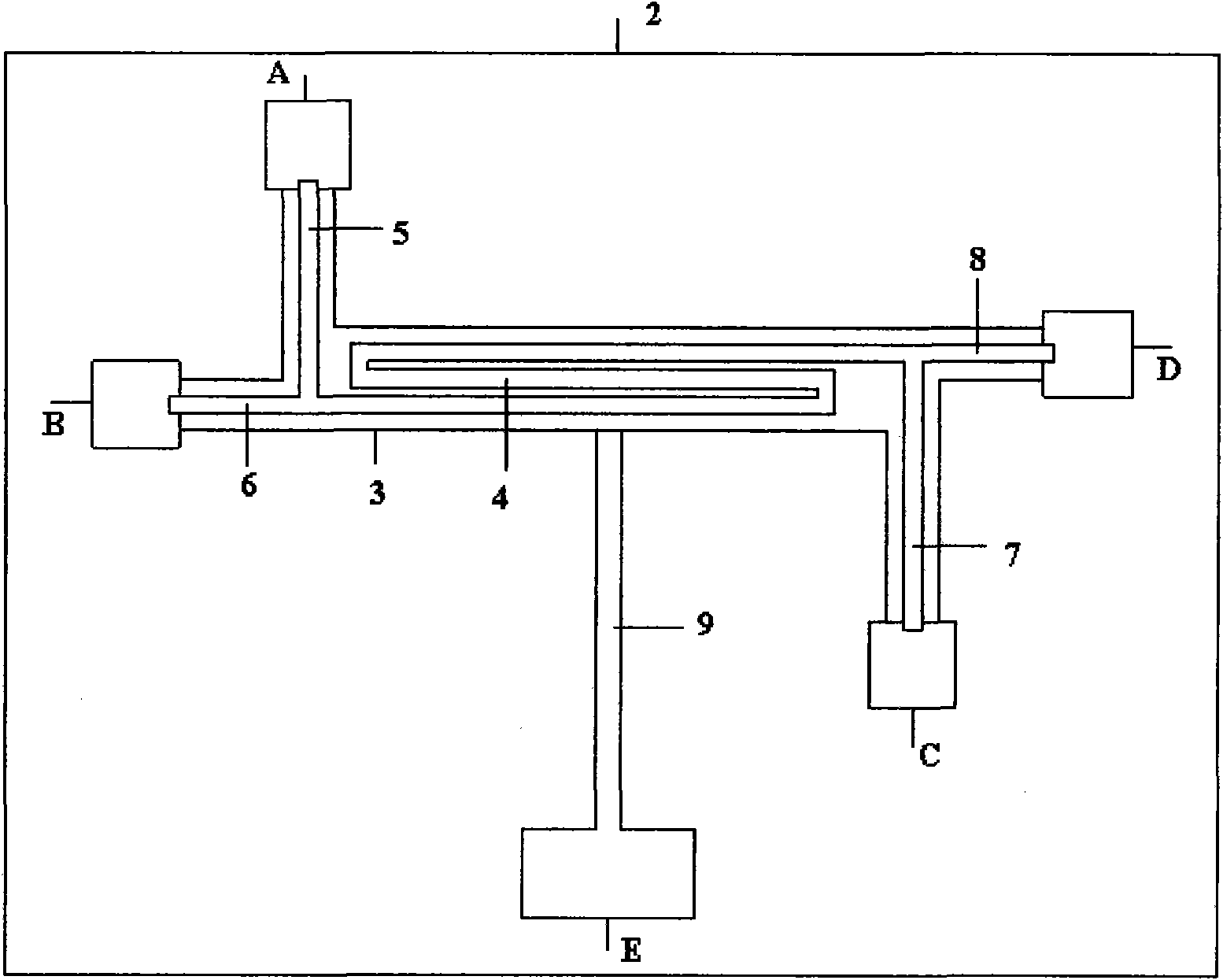

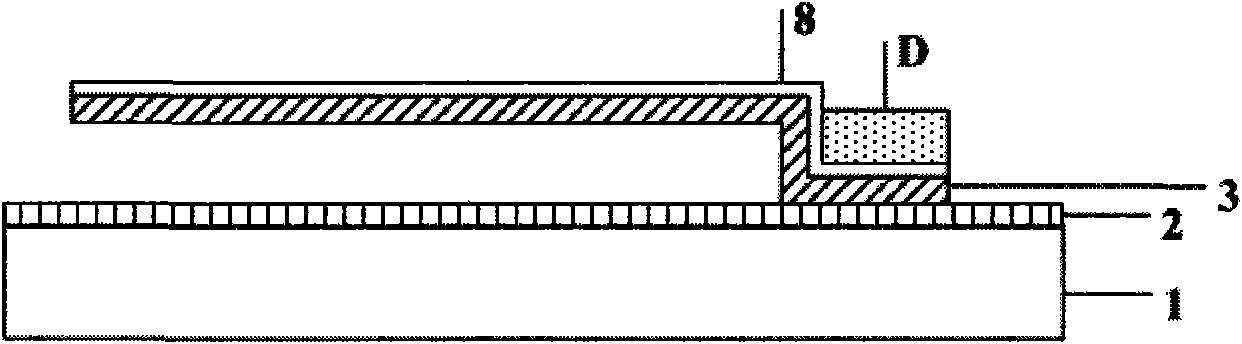

[0019] The present invention proposes a test structure (such as Figure 5 Shown), including: substrate 1, depositing an insulating layer 2 on the substrate 1, depositing a test structure on the insulating layer 2, the test structure including a test unit (such as figure 2 Shown) and a reference unit (e.g. figure 1 Shown), the reference cell structure includes silicon nitride (Si 3 N 4 ) Film support cantilever arm 3, in Si 3 N 4 On the surface of the thin film support cantilever arm 3, a serpentine metal platinum (Pt) heating temperature detector 4 is sputtered, and the two ends of the serpentine heating temperature detector 4 are respectively provided with two leads 5, 6 and 7, 8 made of metal Pt film , Pt thin film leads 5, 6 and 7, 8 are respectively fixed on the insulating layer 2 by metal aluminum (Al) pads A, B and C, D (side structure such as image 3 Shown), the test unit is e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com