Method for preparing piezoelectric polymer functional film with ordered micro-cellular structure by using template

A piezoelectric polymer and microporous structure technology, applied in microstructure technology, microstructure devices, processing microstructure devices, etc., can solve the problem that the mechanical properties and charge storage capacity of porous membranes cannot be effectively controlled or accurately controlled Porous membrane microstructure parameters and other issues, to achieve the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

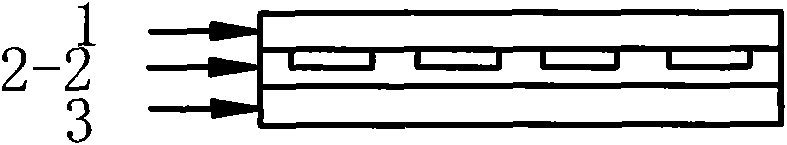

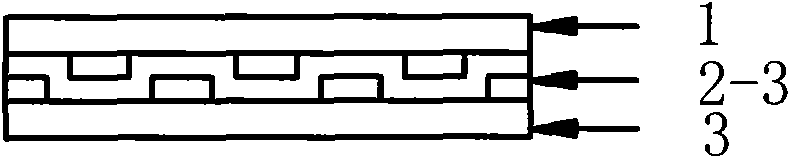

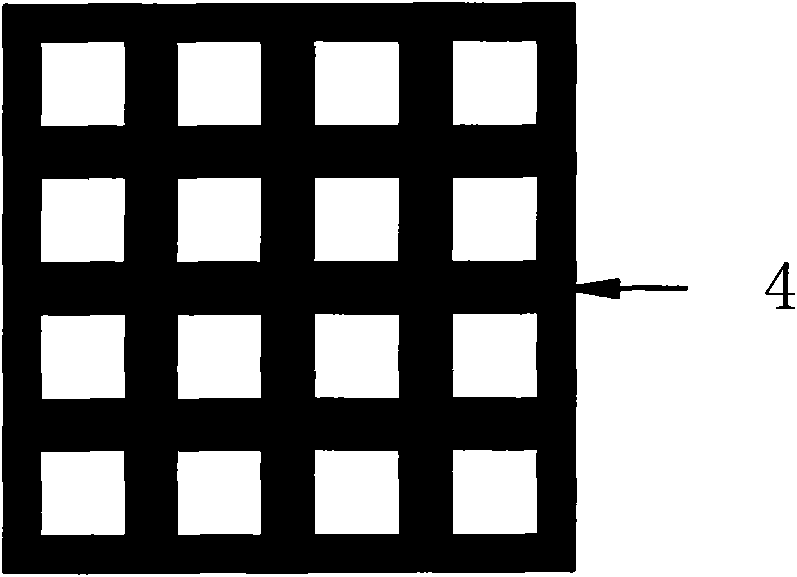

[0036] please see figure 1 , 3 , 4, 5, 6, 7, 9 and 10. First engrave the cells on the commercially available composite copper plate to make template 4, the cells are square, and the square area is 1mm 2, the spacing between the squares is d=0.5mm, and the concave dimension of the spacing is h=0.5mm. A template 4 with a concave-convex ordered pattern was obtained. Select the PTFE with a porosity of 90% produced by DuPont as the organic polymer film 2-1, get an iron plate (steel plate) as the base plate 6, place the template 4 on the base plate 6, the pattern of the template 4 is upward, and the template 4 The organic polymer film 2-1 is placed on the pattern of the organic polymer film 2-1, and the hard 0.2mm PTFE gasket 5 and the bottom plate 6 are stacked in turn on the organic polymer film 2-1. Then, the pressure is applied under the pressure of 3Mpa for 5s, and then the bottom plate 6 and the bottom plate are removed. Gasket 5, removes organic polymer film 2-1 from temp...

Embodiment 2

[0038] please see figure 2 , 3 , 4, 5, 6, 8, 9 and 11. Composite copper plate template is used, the cells are square, and the square area is 1mm 2 , the spacing between the squares is d=0.5mm, and the concave dimension of the spacing is h=0.5mm. The film 2-1 is made of 25 μm dense PTFE produced by DuPont Company, the gasket 5 is made of rubber, and the pressure is applied under a pressure of 6 MPa for 2 minutes to prepare a double-sided concave-convex pattern ordered porous polymer single-layer film 2-3, followed by hot pressing Process: Place the double-sided concave-convex pattern ordered porous polymer single-layer film 2-3 in the middle of the two dense films, place the protective plate 7 and the hard plate 8 on the upper and lower sides of the two dense films, and the two dense films are high melting point films 1 And low-melting point film 3, high-melting point film 1 and low-melting point film 3 all adopt the dense FEP of 12.5 μm produced by DuPont Company, the pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com