Surface modified nano silicon oxide

A surface modification and nanotechnology, which is applied in the field of surface-modified nano-silica and its modification, can solve the problems of reducing the molecular weight of polymer products, and achieve the effect of promoting application and broadening theoretical research.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] 100 parts A-type nano-SiO 2 1500 parts of toluene were added to the container for ultrasonic dispersion for 60 minutes (ultrasonic frequency was controlled at 40KHz) and then added to the reactor, and 10 parts of vinyltriethoxysilane and 5 parts of azobisisobutyronitrile were added to the reactor under stirring. Raise the temperature to boiling, and reflux for 5 hours under high-speed shear at 1000r / min. Cool to 45°C, filter, remove the filtrate, wash with 300 parts of toluene, centrifuge at a speed of 500r / min for 5 minutes, and dry in an infrared oven at a temperature of 50°C. Finally, the modified nano-SiO 2 .

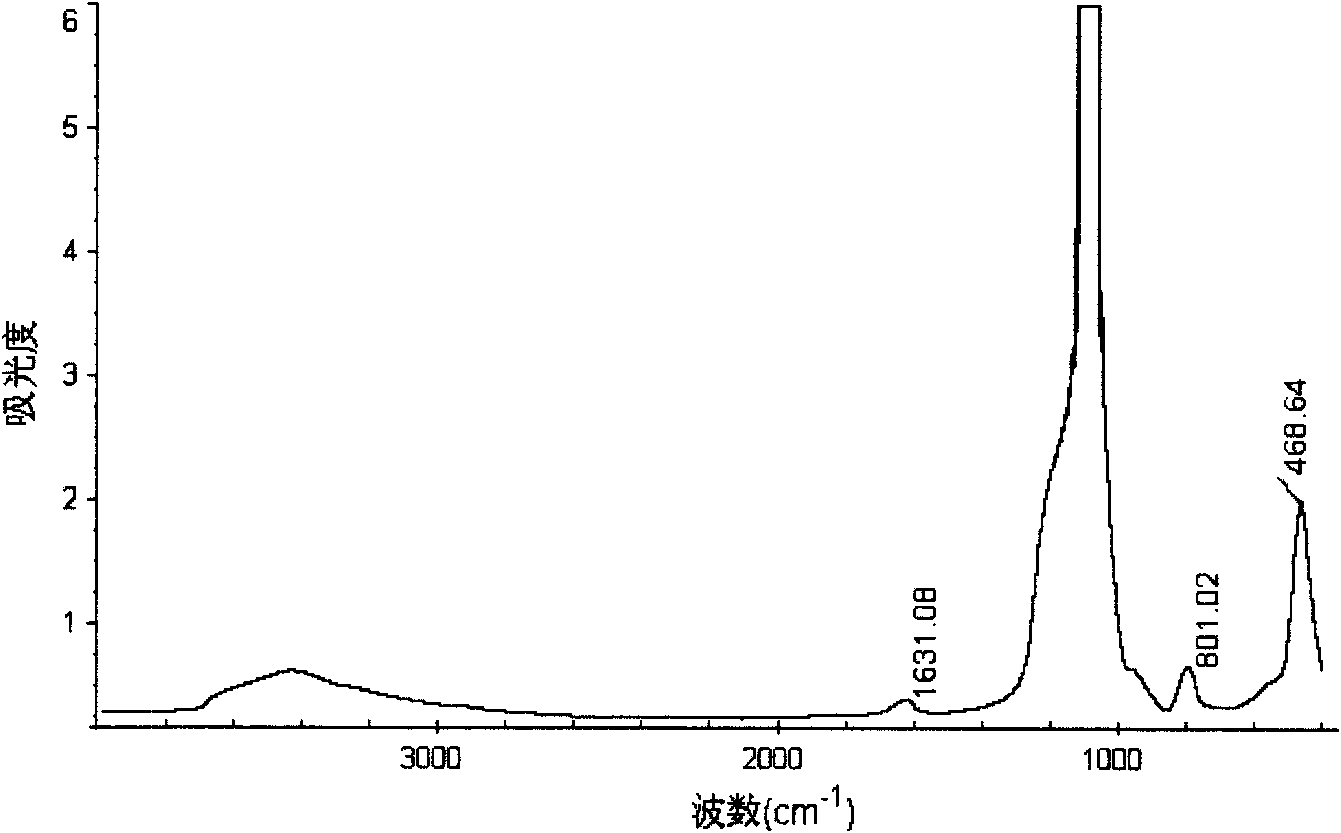

[0060] figure 1 and figure 2 Type A nano-SiO 2 And carry out the nano-SiO of surface modification through the method described in embodiment 1 2 transmission electron microscope pictures. Compare figure 1 and figure 2 It can be found that there are differences in the pictures before and after modification. The results of transmission electron micro...

Embodiment 2

[0064] 100 parts A-type nano-SiO 2 1. Add 500 parts of ethyl acetate into the container and ultrasonically disperse for 30min (ultrasonic frequency is controlled at 60KHz), then add to the reactor, add 2 parts of n-dodecanemercaptan to the reactor under stirring, heat up to boiling, and 300r / min high speed Reflux under shear for 1.5h. Cool to 10°C, filter, remove the filtrate, wash with 300 parts of ethyl acetate, centrifuge at 400r / min for 15 minutes and dry in an infrared oven at a temperature of 45°C. Finally, the modified nano-SiO 2 .

Embodiment 3

[0066] 100 parts B-type nano-SiO 2 , 5000 parts of propanol were added to the container for ultrasonic dispersion for 100min (ultrasonic frequency was controlled at 25KHz) and then added to the reactor, and 25 parts of γ-methacryloxypropyltrimethoxysilane, 15 part of azobisisoheptanonitrile, heated to boiling, and refluxed for 4 hours under high-speed shear at 2000r / min. Cool to 25°C, filter, remove the filtrate, wash with 600 parts of propanol, centrifuge at a speed of 1000r / min for 30 minutes, and dry in an infrared oven at a temperature of 40°C. Finally, the modified nano-SiO 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com