Method for separating and recycling CO2 from mixed gas containing CO2

A technology of separation and recovery, mixed gas, applied in separation methods, dispersed particle separation, chemical separation, etc., can solve the problems of high operating pressure, increased energy consumption, etc., and achieve the effect of saving compression power consumption and excellent solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

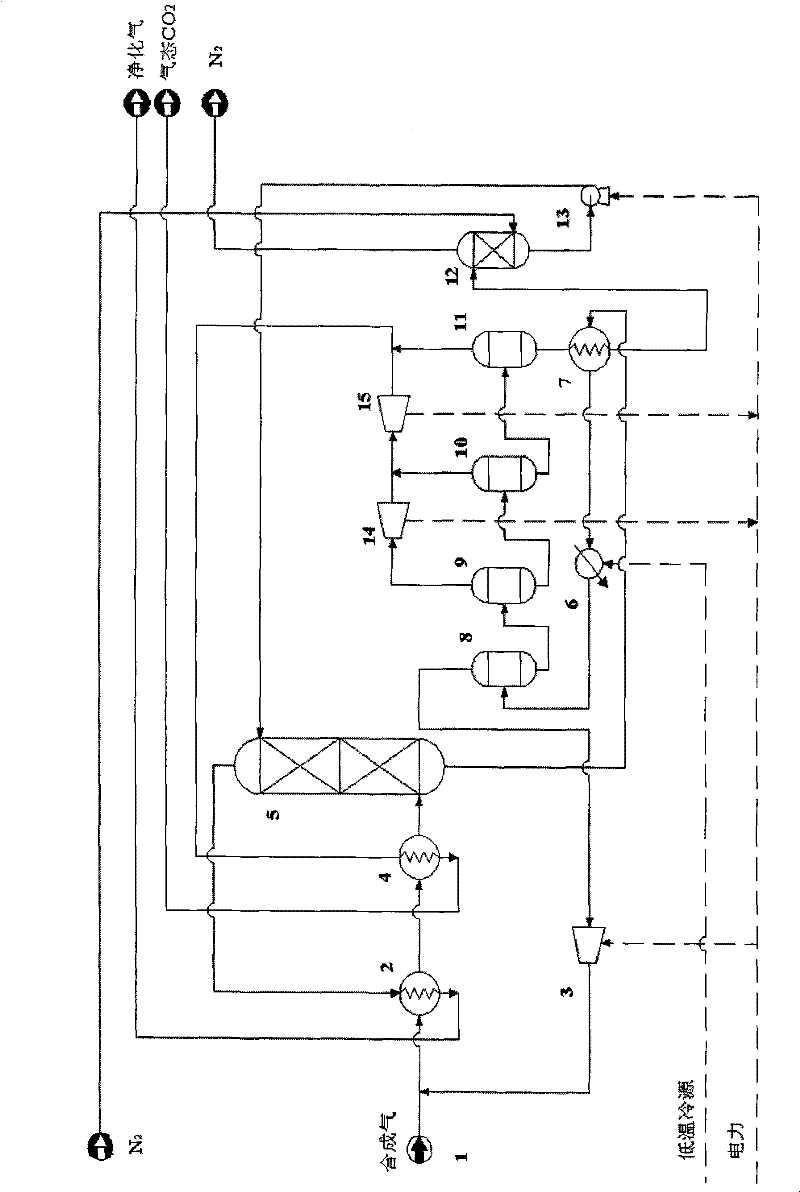

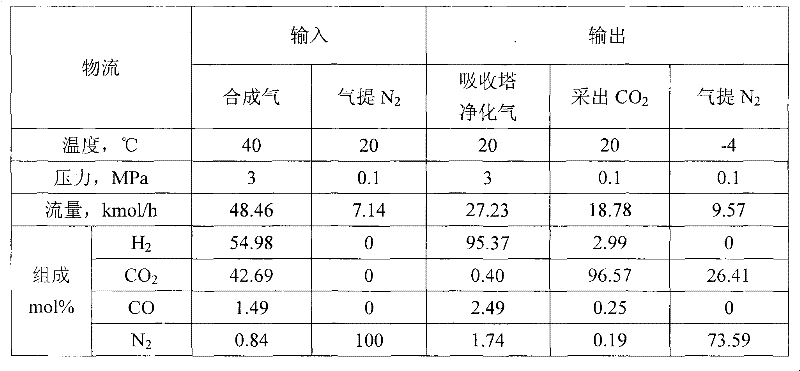

[0020] Embodiment 1: This embodiment is the synthesis gas CO with butyl ether as absorbent 2 Gas recovery process. The raw material mixture gas is synthetic gas, the temperature and pressure are 40°C and 3MPa respectively; it mainly contains CO 2 (42.69%) and H 2 , with a small amount of N 2 and CO. process such as Figure 1 depicts Said:

[0021] (1) Absorption process: The feed gas with a flow rate of 48.46 kmol / h is cooled to 10° C. through heat exchanger I2 and heat exchanger II4, and enters the bottom of absorption tower 5 . Under the operating pressure of 3MPa, the absorbent butyl ether with a flow rate of 48.12kmol / h enters from the top of the absorption tower 5; the purified gas separated from the top of the absorption tower 5 passes through the heat exchanger I2 to recover cooling capacity; 5 The bottom of the tower is rich in CO 2 liquid flow.

[0022] (2) Analysis process: rich CO 2 The liquid flow passes through heat exchanger III7 and cooler 6, and enters...

Embodiment 2

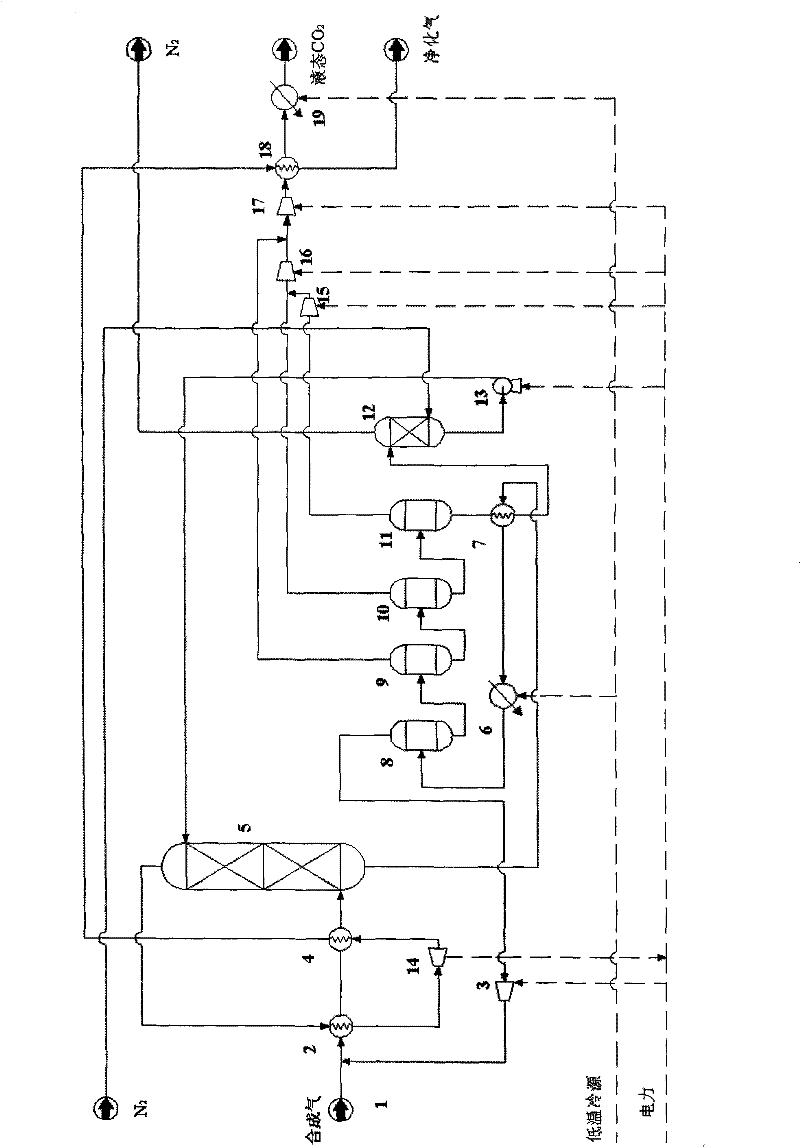

[0027] Embodiment 2: This embodiment uses the mixture of isopropyl ether and butyl ether (molar ratio 1:9) as the gas purification process of the integrated coal gasification combined cycle of the absorbent, and carries out the pre-combustion CO 2 catch. The raw material mixture gas is synthetic gas, the temperature and pressure are 40°C and 3MPa respectively; it mainly contains CO 2 (42.69%) and H 2 , with a small amount of N 2 and CO. process such as Figure 2 depicts Said:

[0028] (1) Absorption process: The feed gas with a flow rate of 48.46 kmol / h is cooled to 10° C. through heat exchanger I2 and heat exchanger II4, and enters the bottom of absorption tower 5 . Under the operating pressure of 3MPa, the flow rate is 39.34kmol / h. The absorbent enters from the top of the absorption tower 5; the purified gas separated from the top of the absorption tower 5 passes through the heat exchanger I2 to recover the cooling capacity once, and recovers it through the expander I14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com