Method for treating waste water polluted by composite chlorophenol with coordination of visible light-laccase

A treatment method and co-processing technology, which can be used in light water/sewage treatment, energy waste water treatment, oxidized water/sewage treatment, etc. It can solve the problems of high equipment requirements, limitations, and inability to get rid of high energy consumption. simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

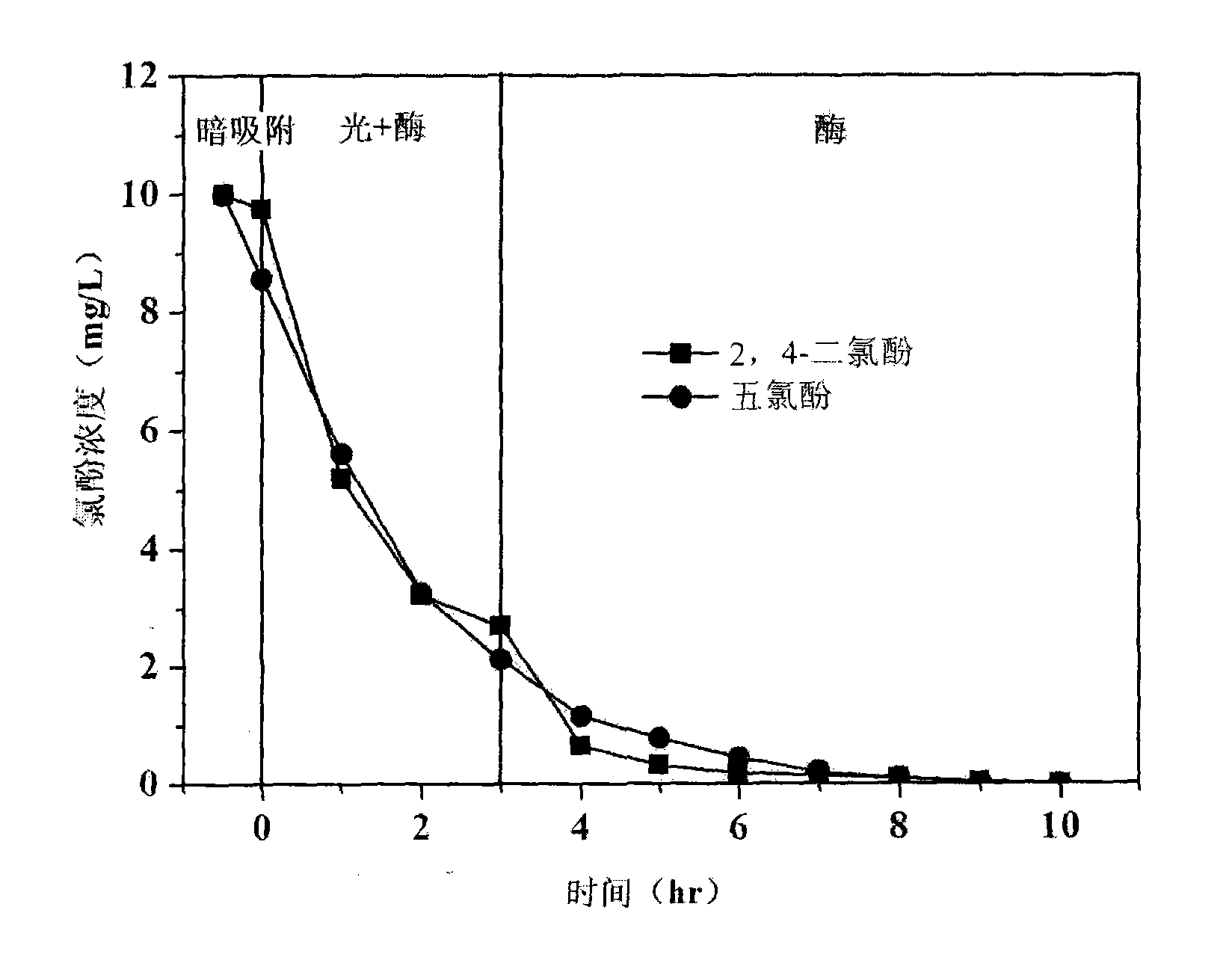

Embodiment 1

[0024] In a cylindrical quartz photocatalytic reactor with a volume of 250 mL, a 200 mL mixed aqueous solution with a concentration of 10 mg / L of 2,4-dichlorophenol and 10 mg / L of pentachlorophenol was used as the target object. First, adjust the pH value to 3-5 with acetic acid and / or sodium hydroxide. Add 2 mL of an aqueous solution of laccase (copper-containing diphenol dioxide oxidoreductase, classification number EC 1.10.3.2) with a concentration of 1 mg / mL, and stir continuously to make it evenly mixed. Then add 0.1 g of titanium-bismuth composite visible light catalyst, and continue to stir for 30 minutes to make it reach adsorption equilibrium. The xenon lamp (Beijing Tianmai Henghui Light Source Electric Co., Ltd., XG1000, power 1000w) was placed vertically on the side of the quartz reactor, the distance between the xenon lamp and the reactor was 5 cm, and a cut-off filter (Shanghai Moray Optoelectronics Co., Ltd., VIS -LPF400, cut-off wavelength 400nm) apart. Turn ...

Embodiment 2

[0027] The specific implementation method is the same as in Example 1. The amount of laccase was adjusted to 1 mL of laccase aqueous solution with a concentration of 1 mg / mL, and the amount of photocatalyst was adjusted to 0.04 g. After reacting for 3 hours, the degradation rate of 2,4-dichlorophenol was 43%, and that of pentachlorophenol was 51%. The enzyme-catalyzed reaction was continued for 7 hours, and the degradation rate of 2,4-dichlorophenol was 87.5%, and that of pentachlorophenol was 90.4%.

Embodiment 3

[0029] Specific implementation method embodiment 1. The amount of laccase was adjusted to 3 mL of laccase aqueous solution with a concentration of 1 mg / mL, and the amount of photocatalyst was adjusted to 0.15 g. After reacting for 3 hours, the degradation rate of 2,4-dichlorophenol was 81.1%, and that of pentachlorophenol was 90.2%. The enzyme-catalyzed reaction was continued for 7 hours, and the degradation rate of 2,4-dichlorophenol was 99.5%, and the degradation rate of pentachlorophenol was 99.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com