Metal structure electrostatic-driven MEMS relay and preparation method thereof

An electrostatic drive, metal structure technology, applied in the direction of electrostatic relays/electro-adhesion relays, relays, microstructure technology, etc., can solve the problems of high driving voltage, unable to load current, small heat capacity, etc., and achieve high yield and consistent process Good performance and low driving voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

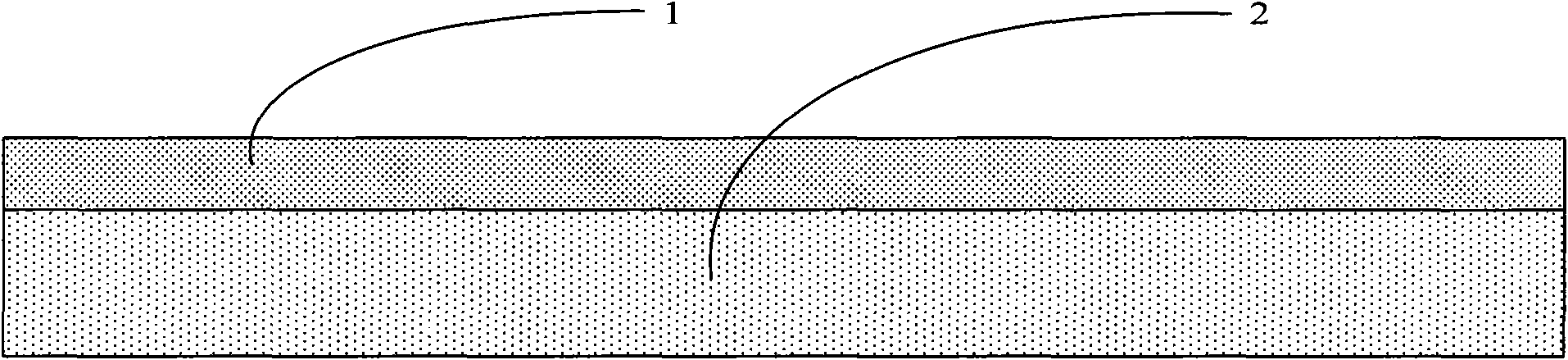

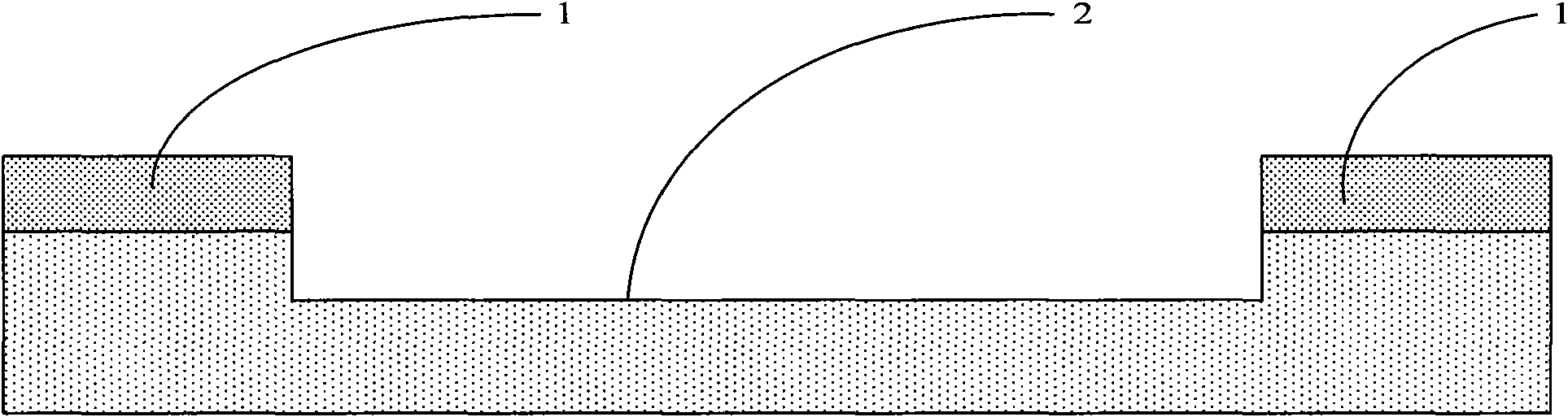

[0050] The metal of the MEMS relay structure is formed by an electroplating process, including two parts of a structural support layer and a surface structure layer. Specifically, a metal seed layer and a barrier layer (transition layer) are formed on the substrate surface through techniques such as sputtering and evaporation. ), the adhesion layer, the materials include Ti / Pt / Au, Cr / Au, Ti / Cu, Ta / TaN / Cu, Ru, Ir or alloy materials and other metal materials. The first requirement for the seed layer is a conductor. In addition, the seed layer needs to have good adhesion and stable temperature characteristics between the seed layer and the substrate, such as Ti. The structure can be formed by electroplating, and the electroplating materials include metal materials such as Cu and Au.

[0051] Structural part:

[0052] The electrostatically driven relay structure can be divided into a driving part (upper plate 7 , lower plate 4 ) and a contact electrode 6 . The upper plate is mai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com