Lithium-ion battery electrolyte and lithium-ion battery containing same

A lithium-ion battery and electrolyte technology, applied in the field of lithium-ion batteries, can solve problems such as poor safety performance of electrolyte, and achieve the effects of improving safety performance and suppressing gas generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

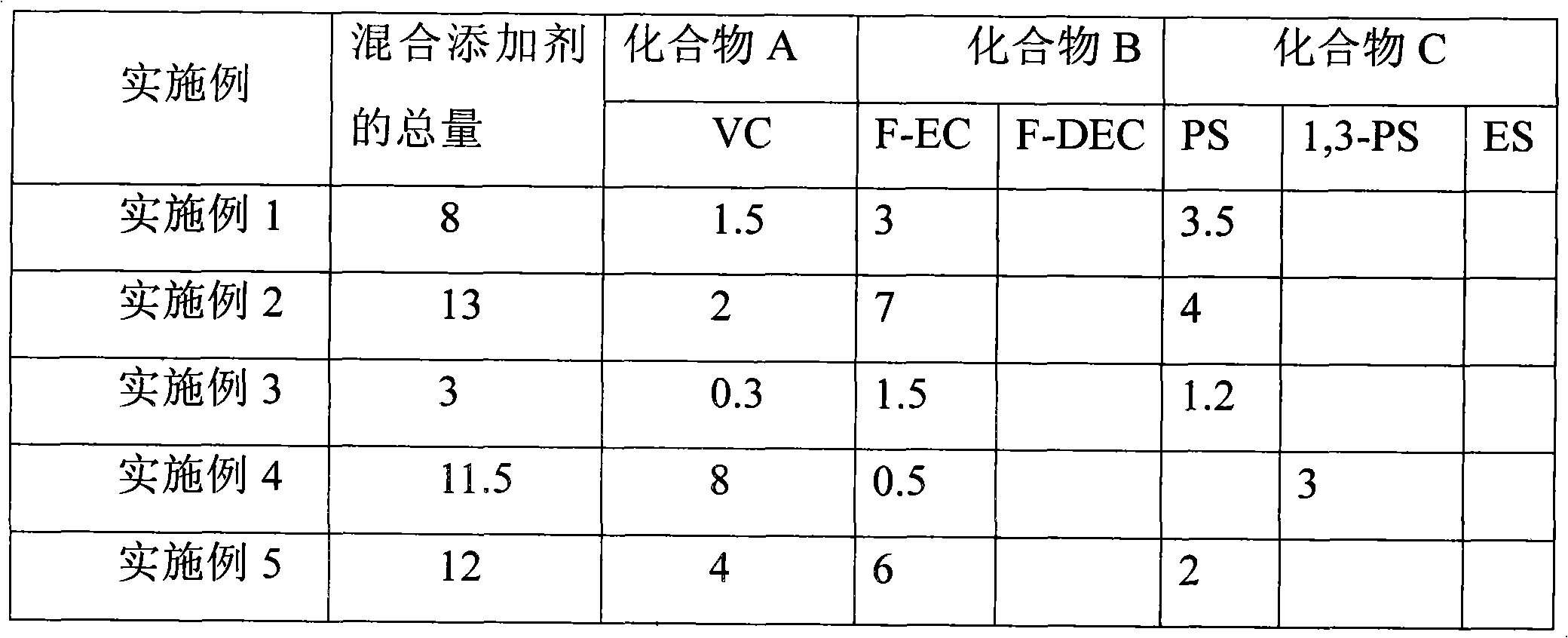

Embodiment 1

[0037] This embodiment is used to illustrate the lithium ion battery electrolyte provided by the present invention and the lithium ion battery thereof.

[0038] (1) Preparation of electrolyte

[0039] Prepare the mass ratio of organic solvent ethylene carbonate (EC): divinyl carbonate (DEC): gamma-butyrolactone (GBL)=2: 2: 1 combined solvent 87.5g, add the LiPF of 12.5g wherein 6 , to prepare bulk electrolyte, then add 1.5gVC, 3gF-EC, 3.5gPS to it and mix evenly, add molecular sieve to remove water, and let stand for 1 day. Pour out the electrolyte solution after water removal to obtain the experimental electrolyte solution.

[0040] In the non-aqueous electrolyte, the VC in the mixed additive accounts for 1.5% by mass of the electrolyte, the F-EC is 3%, and the PS is 3.5%.

[0041] (2) Preparation of positive electrode

[0042] 8.7 kg of N-methylpyrrolidone (NMP), 1 kg of acetylene black and 0.3 kg of polyvinylidene fluoride (PVDF) powder were mixed and stirred for 5 minut...

Embodiment 2

[0050] This embodiment is used to illustrate the lithium ion battery electrolyte provided by the present invention and the lithium ion battery thereof.

[0051] Lithium-ion batteries were prepared according to the method of Example 1, wherein the difference was that the quality of the mixed additives added in the preparation of the electrolyte was different, including 2gVC, 7gF-EC, and 4gPS.

[0052] In the non-aqueous electrolyte, the mass percent of VC in the mixed additives in the electrolyte is 2%, F-EC is 7%, and PS is 4%.

[0053] Finally made LP043450A lithium ion battery A2.

Embodiment 3

[0055] This embodiment is used to illustrate the lithium ion battery electrolyte provided by the present invention and the lithium ion battery thereof.

[0056] Lithium-ion batteries were prepared according to the method of Example 1, wherein the difference was that the quality of the mixed additives added in the preparation of the electrolyte was different, including 0.3gVC, 1.5gF-EC, and 1.2gPS.

[0057] In the non-aqueous electrolyte, the VC in the mixed additive accounts for 0.3% by mass of the electrolyte, the F-EC is 1.5%, and the PS is 1.2%.

[0058] The finally made LP053450A lithium ion battery A3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com