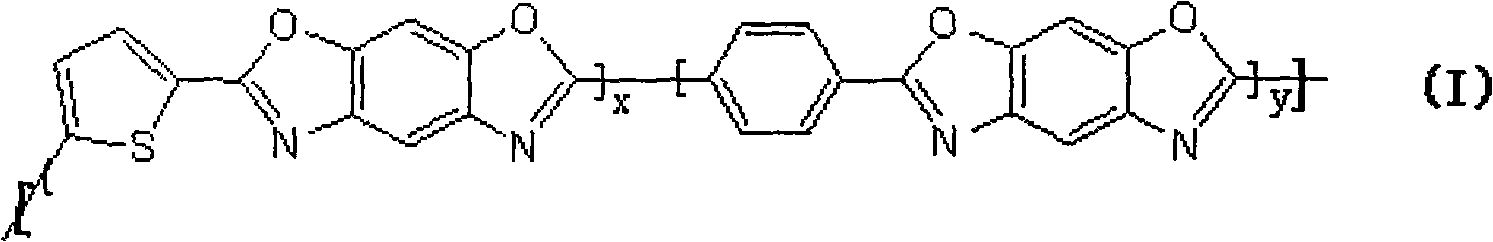

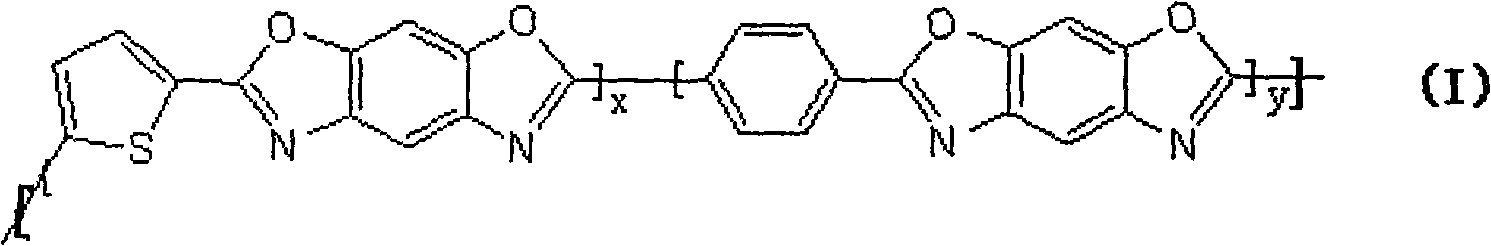

Polybenzobisoxazole polymer containing thiophenic sulfur and preparation method thereof

A technology of polybenzoxazole and benzobisoxazole, which is applied in the field of polybenzoxazole polymer containing thiophene sulfur and its preparation, can solve the problems of high production cost of terephthalic acid, achieve high strength, improve Processability, good oxidation resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

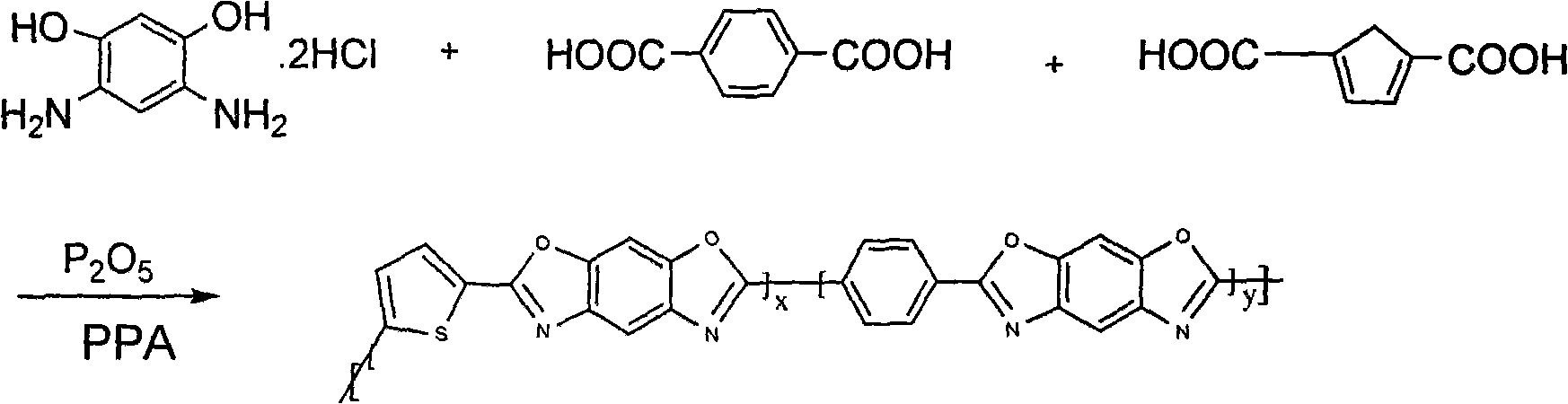

Method used

Image

Examples

Embodiment 1

[0030] In a 125mL four-neck flask equipped with a stirring device, a condenser, a drying tube and a thermometer, under the protection of an inert nitrogen gas, 10.653g (0.05mol) DAR, 4.154g (0.025mol) terephthalic acid, 4.304g (0.025mol) thiophenedicarboxylic acid, 8.315g phosphorus pentoxide, 119.093g polyphosphoric acid (the mass fraction is 82% based on phosphorus pentoxide, the same below), stir and heat the reaction materials to 40-50°C for 12 hours During this period, HCl is removed under reduced pressure, and the temperature is raised to 90-100°C for 12 hours until the pH test paper is used to detect neutrality at the gas escape port, which means that the system has completely removed HCl;

[0031] Then add 4.208g of phosphorus pentoxide, raise the temperature to 130°C for 12h, 150°C for 12h, 170°C for 12h, 180°C for 12h and 220°C for 12h to complete the polymerization reaction.

[0032] The reaction solution was refluxed with water and dilute sodium hydroxide solution,...

Embodiment 2

[0035] Raw material and its add-on, solvent adding method and its add-on are the same as embodiment 1. In the initial stage, stir and heat to 50-60°C for 12 hours, during which HCl is removed under reduced pressure, and the temperature is raised to 90-100°C for 12 hours to ensure complete removal of HCl;

[0036] Then add phosphorus pentoxide, raise the temperature to 130°C for 24h, 150°C for 24h, 170°C for 24h, 180°C for 12h and 200°C for 12h to complete the polymerization reaction.

[0037] Adopt same test method, the intrinsic viscosity of gained polymer is 5.6dL / g; Solid 13 C NMR analysis results (ppm): δ=161.67, 148.14, 139.28, 128.29, 111.19, 110.21, 109.19, 94.09.

Embodiment 3

[0039] Raw material and its add-on are with embodiment 1. The way of solvent addition and its addition amount and reaction conditions are as follows: add 29.736g phosphorus pentoxide and 91.36g polyphosphoric acid at the beginning stage, stir and heat to 50-60°C for 12 hours, during which HCl is removed under reduced pressure, and the temperature is gradually raised to React at 80-90°C for 12 hours to ensure complete removal of HCl;

[0040] Then add 14.868g of phosphorus pentoxide, raise the temperature to 130°C for 24h, 150°C for 24h, 170°C for 24h, 180°C for 12h and 200°C for 12h to complete the polymerization reaction.

[0041] Adopt same test method, the intrinsic viscosity of gained polymer is 9.8dL / g; Solid 13 C NMR analysis results (ppm): δ=161.67, 148.15, 139.28, 128.28, 111.19, 110.21, 109.18, 94.09.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com