Escherichia coli strain for efficiently converting glutamine to synthesize L-theanine and application thereof

A technology of Escherichia coli and glutamine, which is applied to Escherichia coli strains that efficiently transform glutamine to synthesize L-theanine and its application field, and can solve problems such as restricting applications and screening for efficient transformation of theanine Escherichia coli strains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1 strain screening

[0021] 23 Escherichia coli strains isolated from tea tree soil were inoculated into LB medium containing ethylamine (0.45M) for overnight culture.

[0022] After 24 hours of culture, the cultured E. coli strains were observed with a microscope, and it was found that the cell morphology of 3 strains of E. coli strains was normal and had a large number of cells, while the cell morphology of the other 20 strains was irregular and the number of cells was very large. few.

[0023] Add 400mM glutamine and 1M ethylamine to E. coli cells in the logarithmic growth phase for biotransformation. After 12 hours of further fermentation, most of the glutamine will be synthesized by L-theanine synthase in E. coli strains converted to theanine.

[0024] The results of theanine conversion by fermentation of the above three strains of Escherichia coli were analyzed by HPLC, and one of the strains of Escherichia coli had a conversion rate of glutamine exceedi...

Embodiment 2

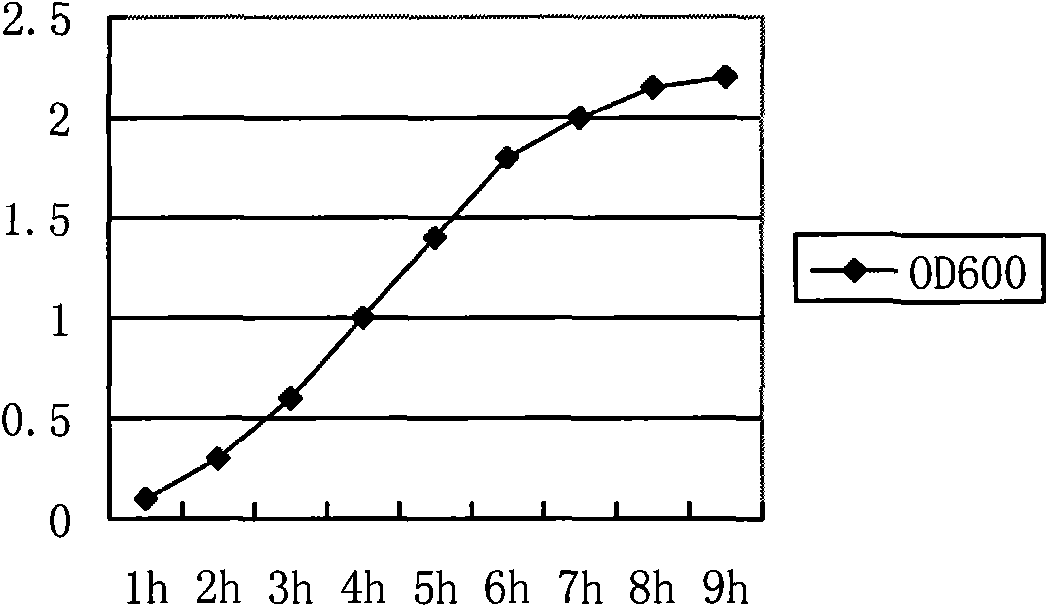

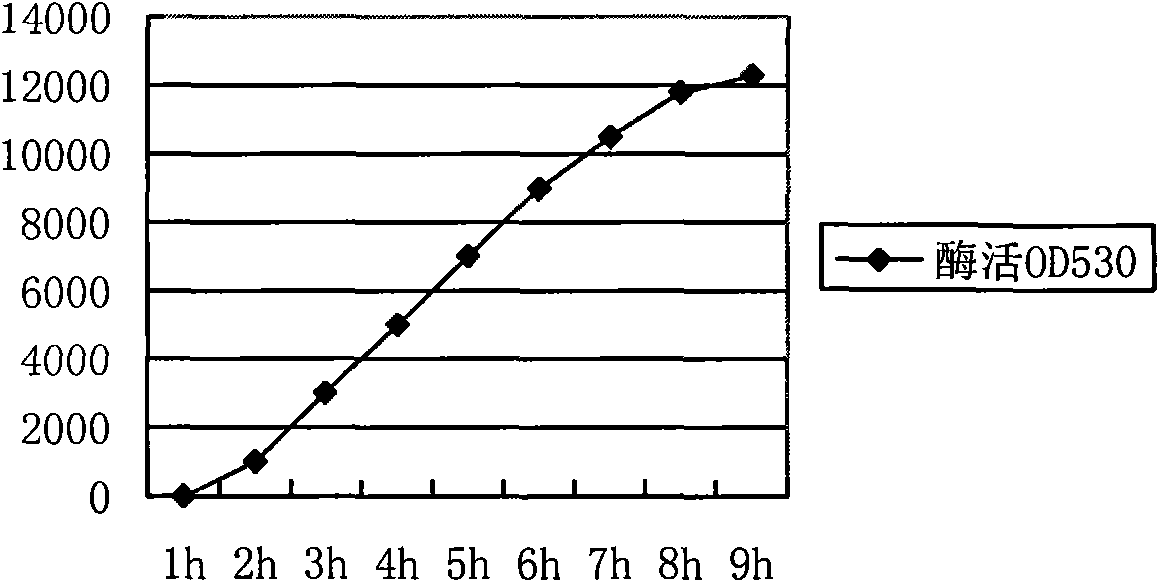

[0027] (1) Inoculate the screened Escherichia coli Nanshi No. 1 in LB solid medium, containing 10g of peptone per liter, 5g of yeast extract, 10g of NaCl, 15g of agar, culture at 37°C for 12 hours, and inoculate a single colony in 10mL LB liquid medium, each liter of medium contains 10g of peptone, 5g of yeast extract, 10g of NaCl, dilute to 1 liter with deionized water, shake and culture at 37°C for 12h, then inoculate 1mL into 100mL of LB liquid medium, at 37°C Shake culture for 6~8h, OD 600 reach 2.0~2.2( figure 1 ), enzyme activity unit (Nanjing Jiancheng Biological Kit detection) OD 530 Reach 12000~14000( figure 2 ), collected by centrifugation for 15 minutes, and crushed under high pressure to obtain theanine synthase.

[0028] (2) Add 4000 units of theanine synthase per 0.6M / L glutamine and 70% (mass) ethylamine aqueous solution, after 40-48 hours of enzyme reaction at 25°C, it is found that it is sensitive to glutamine by HPLC Amide conversion was as high as 70%. ...

Embodiment 3

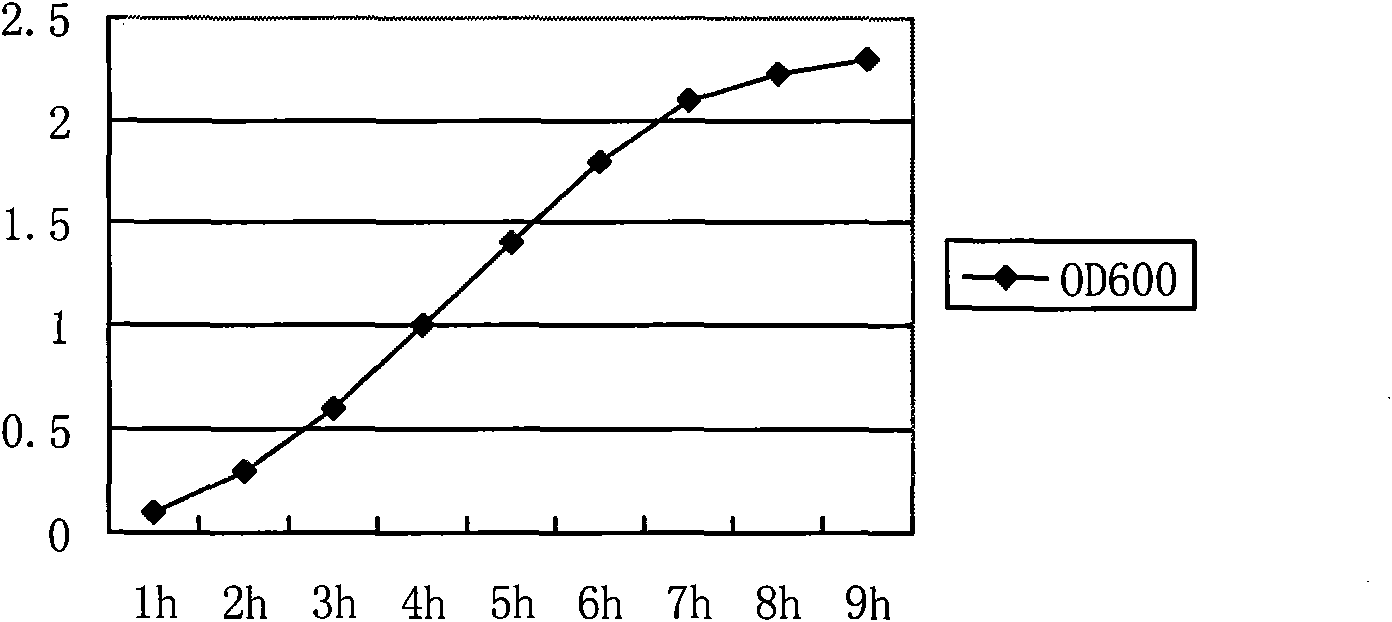

[0031] (1) Inoculate the screened Escherichia coli Nanshi No. 1 in LB solid medium, containing 10g of peptone per liter, 5g of yeast extract, 10g of NaCl, 15g of agar, culture at 37°C for 12 hours, and inoculate a single colony in 10mL Autonomous MB medium with Na per liter medium 2 HPO 4 15g, KH 2 PO 4 5g, NaCl 1g, NH 4 Cl 2g, glycerol 3ml, peptone 10g; culture with shaking at 37°C for 12h, then inoculate 1mL into 100mL autonomous MB liquid medium, culture with shaking at 37°C for 6-8h, OD 600 reach 2.1~2.3( image 3 ), enzyme activity unit (Nanjing Jiancheng Biological Kit detection) OD 530 Reach 15000~16000( Figure 4 ), centrifuged for 15 minutes to collect the thalline, and crushed under high pressure to obtain the gamma-glutamyl transferase synthesized by theanine

[0032] (2) Add 5000 units of theanine synthase per 0.6M / L glutamine and ethylamine aqueous solution, and after 40-48 hours of enzymatic reaction at 25°C, it is found that the conversion rate of gluta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com