Melting and iron-smelting device of heat storage type electric arc furnace

An electric arc furnace and regenerative technology, which is applied in the field of molten ironmaking equipment, can solve problems affecting the quality of reduced products and oxidation of reduced products, and achieve the effects of saving high-power distribution equipment, preventing oxidation, and maintaining power balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

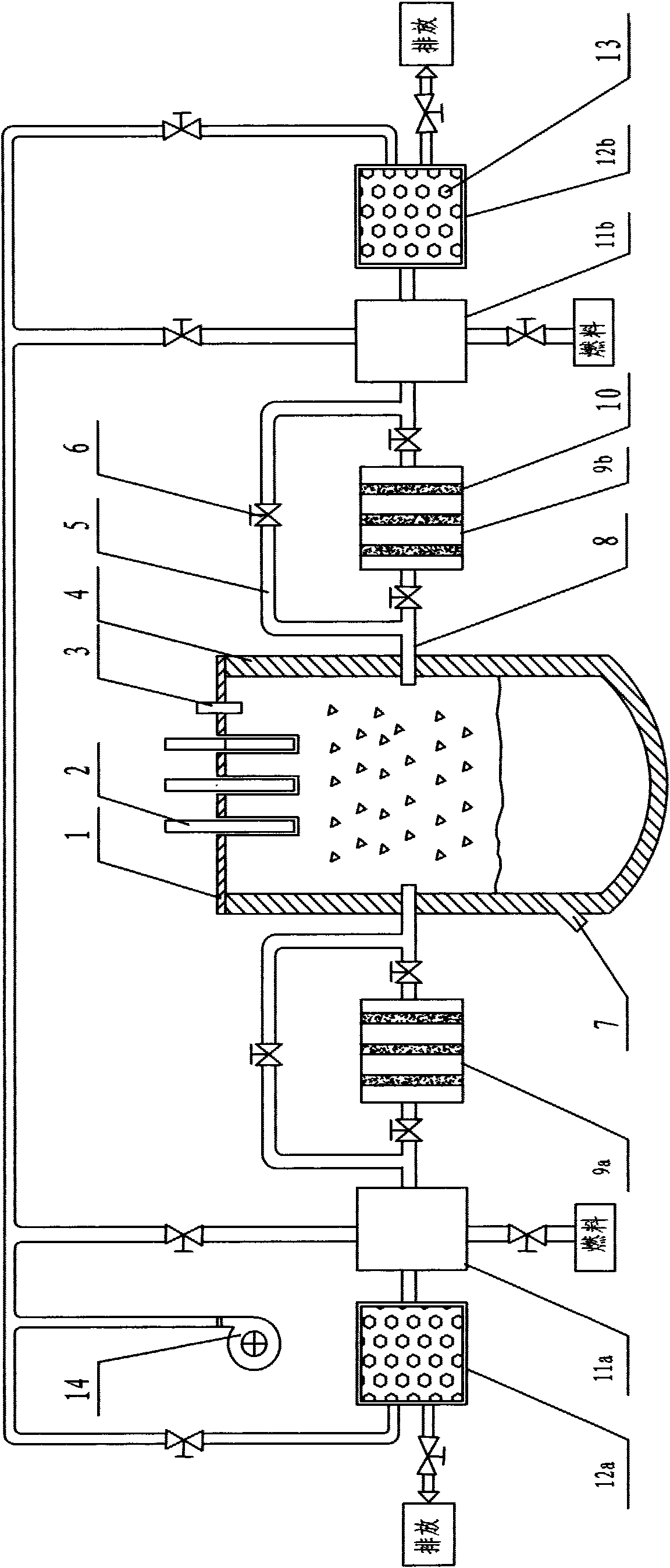

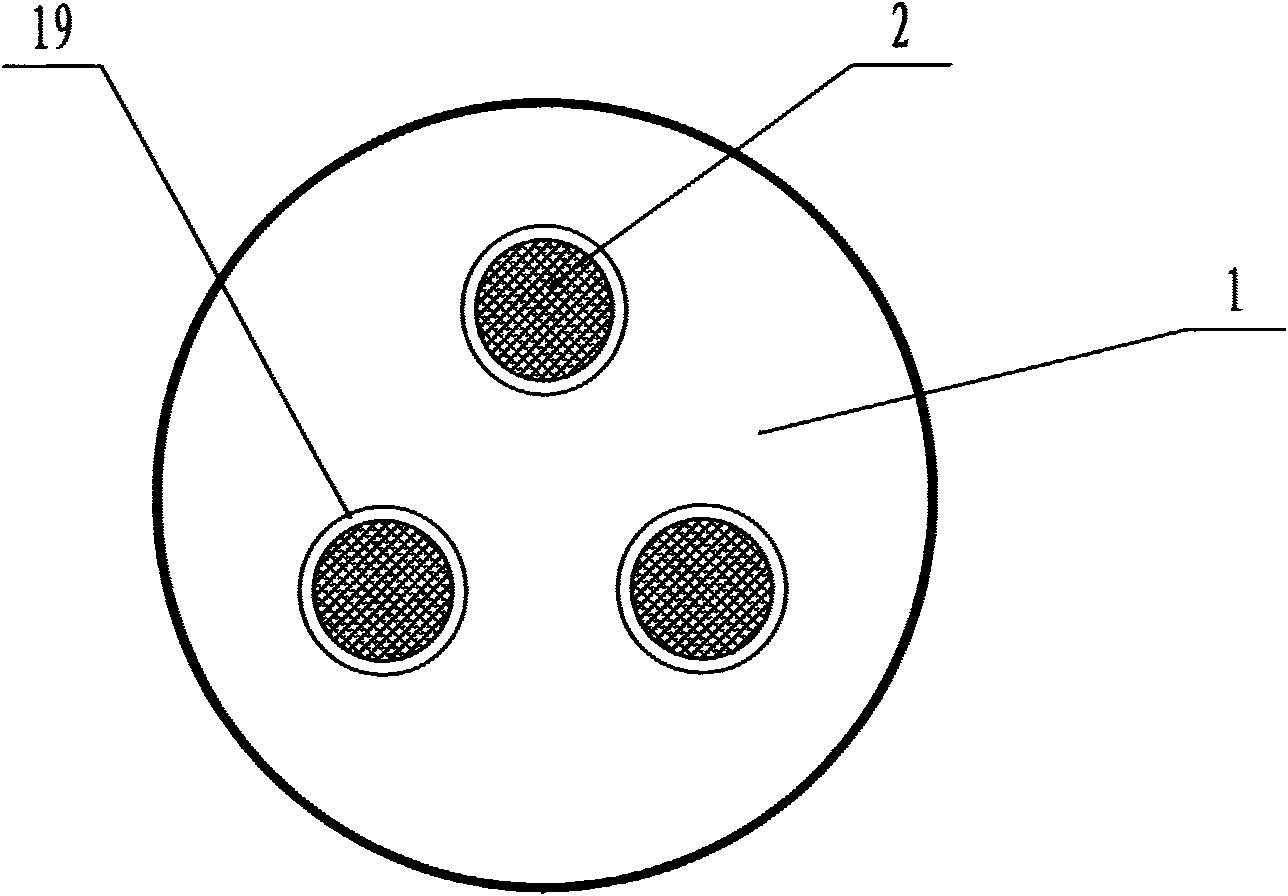

[0024] The regenerative electric arc furnace melting ironmaking device of the present invention is as figure 1 Shown, comprise furnace body 4, furnace cover 1, charging equipment and discharging equipment, there is molten iron outlet 7 at the bottom of furnace body 4, as image 3 As shown, there are three electrode jacks 19 on the furnace cover 1, which are respectively inserted into the electrodes 2, and the three electrode jacks are distributed in a triangle. A pair of combustion chambers 11a, 11b, a pair of heat accumulators 12a, 12b, and a pair of coal gasification boxes 9a, 9b outside the furnace body 4, and two sets of heat storage / coal gasification equipment are installed on opposite sides of the furnace body 2. Three layers of coal grids 10 are arranged in the coal gasification box, and the coal grids are a meshed rectangular structure made of barbed wire. The upper part of the coal grid has a coal inlet, the lower part has a coal ash outlet, and the coal inlet and th...

Embodiment 2

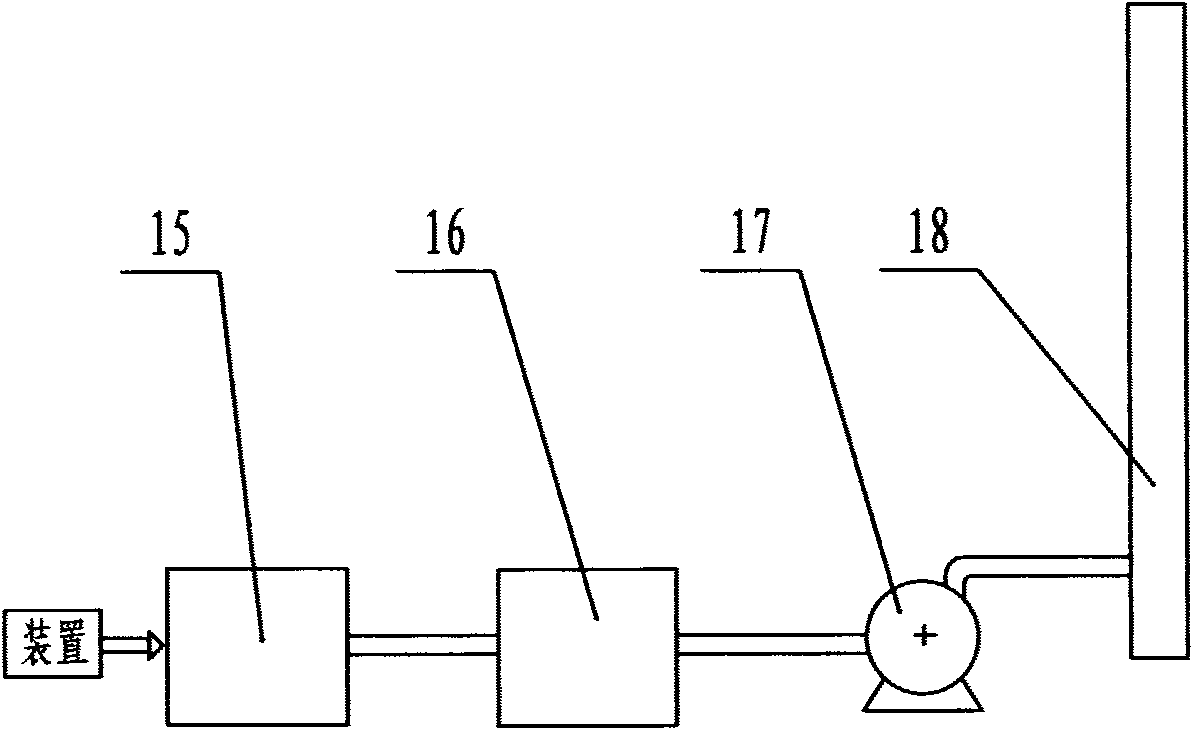

[0029] Another embodiment of the present invention is that three sets of regenerative electric arc furnace melting iron-making devices are installed side by side and connected in series for operation. Each set of devices is provided with two sets of regenerative / coal gasification equipment 23, located on opposite The heat storage / coal gasification equipment includes a combustion chamber, a heat accumulator, a coal gasification box and connecting pipelines. The air supply system, fuel system and exhaust gas discharge system are shared equipment. The operation mode between the electric arc furnace, regenerator, combustion chamber and gas box of each set of equipment is the same as that of embodiment 1. Such as Figure 4 As shown, the furnace bodies 4a, 4b, and 4c of the electric arc furnaces of the three sets of devices are connected together side by side, and a connecting hole 20 is provided between the furnace body 4a and the furnace body 4b, and between the furnace body 4b a...

Embodiment 3

[0031] Another embodiment of the present invention is as Figure 5 As shown, three electric arc furnaces are arranged in a ring. The three electric arc furnace bodies 4a, 4b, and 4c are arranged in a triangular ring shape, each furnace body is installed close to the other two furnace bodies, and a connecting hole and a plug-in valve 21 are provided between each two furnace bodies. Each electric arc furnace is equipped with two sets of heat storage / coal gasification equipment 23, which are located on the two wings of the furnace body, and a set of heat storage / coal gasification equipment 23 of two adjacent electric arc furnaces are arranged together in a "herringbone" shape. The air supply system, fuel system and exhaust gas discharge system are shared equipment. An electrode hanging column 22 is arranged in the middle of the three furnace bodies for hanging the electrodes, and the electrodes are inserted in turn between the furnace bodies to carry out the melting process of r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com