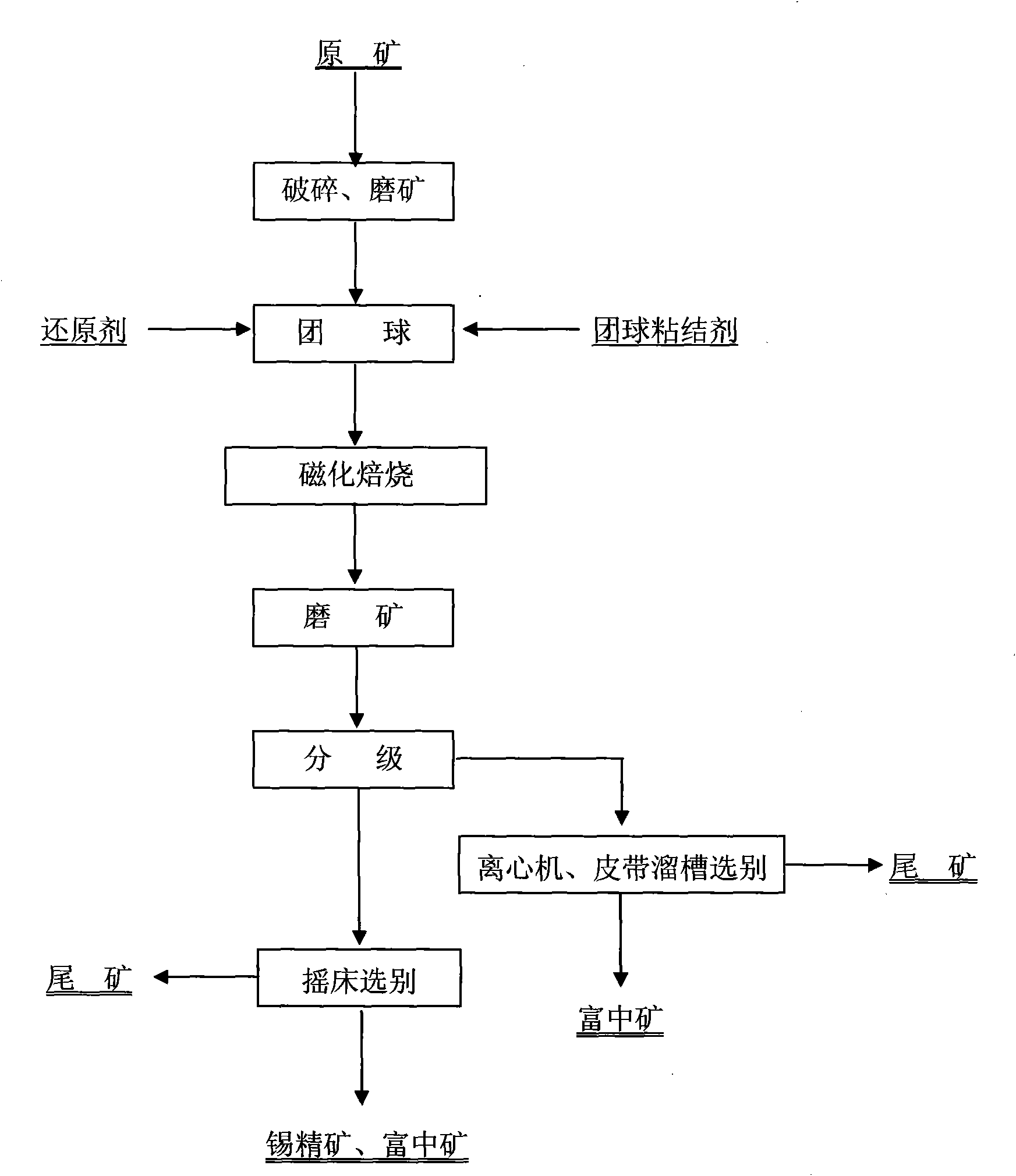

Combined process flow processing method of high-iron low-tin oxidized ore

A high-iron, low-tin, and treatment method technology, which is applied in the field of non-ferrous metallurgy and mineral processing, can solve the problems that tin and iron resources have not been effectively utilized, difficult separation of tin and iron in mineral processing technology, complex properties, etc., to achieve good application and Promoting prospects, simplifying the beneficiation process, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Raw ore properties of high iron and low tin oxide ore: chemical composition, Sn0.58%, Fe47.00%, S0.026%, As0.040%, SiO 2 10.41%, Al 2 o 3 9.51%, CaO0.241%, MgO0.154%. The raw ore is crushed to 2mm particle size analysis, the yield of 0.074mm grade is 44.58%, the tin metal rate is 40.51%; the 0.010mm particle size yield is 29.09%, the tin metal rate is 20.51%. Useful minerals are mainly cassiterite, with a mineral content of 0.31%. Metal minerals are mainly hematite, clay, and iron-stained clay, with a mineral content of 54.23%. Non-metallic minerals are mainly quartz and feldspar, accounting for Amount 5.25%. The distribution rate of cassiterite tin accounts for 84.62%, and the distribution rate of acid-soluble tin accounts for 15.38%. Part of tin is in the form of fine grains, fine grained cassiterite embedded in hematite, iron stained clay, clay, and gangue minerals. The grain size of cassiterite crystals varies greatly, and the symbiosis relationship between cas...

Embodiment 2

[0023] Raw ore properties of high iron and low tin oxide ore: chemical composition, Sn0.66%, Fe41.92%, S0.54%, As0.352%, SiO 2 15.69%, Al 2 o 3 3.23%, CaO0.211%, MgO3.06%. The primary particle size analysis of the raw ore shows that the yield of 0.074mm grade is 35.68%, and the tin metal rate is 53.55%; the yield of 0.010mm particle size is 15.12%, and the tin metal rate is 6.77%. Tin element mainly occurs in the form of cassiterite, accounting for more than 95% of the total. The distribution rate of tin in visible cassiterite accounts for 73.02%, the distribution rate in limonite accounts for 11%, and the distribution rate in iron stained clay and clay ore accounts for 12%. When the ore is broken to 1mm, 22.70% tin is still wrapped in limonite and other minerals in the form of fine particles. Iron element mainly occurs in limonite, accounting for more than 95% of the total iron. Tin and iron are slightly symbiotic, and it is difficult to separate tin and iron, which is a...

Embodiment 3

[0026] Properties of tin stockpiling tailings: chemical multi-element analysis, Sn0.35%, Fe25%, Pb0.22%, Cu0.43%, SiO 2 27.10%, CaO7.64%, Al 2 o 3 8.01%, MgO1.935%. The particle size analysis of the sample shows that the yield of 0.074mm grade is 57.5%, and the tin metal rate is 59.92%; the yield of 0.010mm particle size is 15.97%, and the tin metal rate is 11.55%. Tin is dominated by cassiterite, whose tin content accounts for more than 90% of the total tin; iron is mainly limonite, followed by hematite and earthy iron minerals; It is about 45%, and the rest are densely symbiotic with iron minerals such as limonite and hematite, and mainly exist in the form of inclusions, and the particle size diameter is between 0.005 and 0.030mm. The monomer dissociation degree of the 0.074mm particle size of the sample is 25.31%, and when the particle size reaches 0.037mm, the monomer dissociation degree reaches 83.71%. The symbiosis relationship of cassiterite in this sample is comple...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com