Method for detecting content of titanium dioxide in emulsion or milk powder

A detection method and technology of titanium dioxide, which are applied in the preparation of test samples, thermal excitation analysis, material excitation analysis, etc., can solve the problems of health hazards, the inability to complete the detection test by the wet digestion method, and the inconclusiveness of soluble titanium compounds, and achieve economical savings. Energy and environmental protection, low element loss and pollution rate, and stable test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

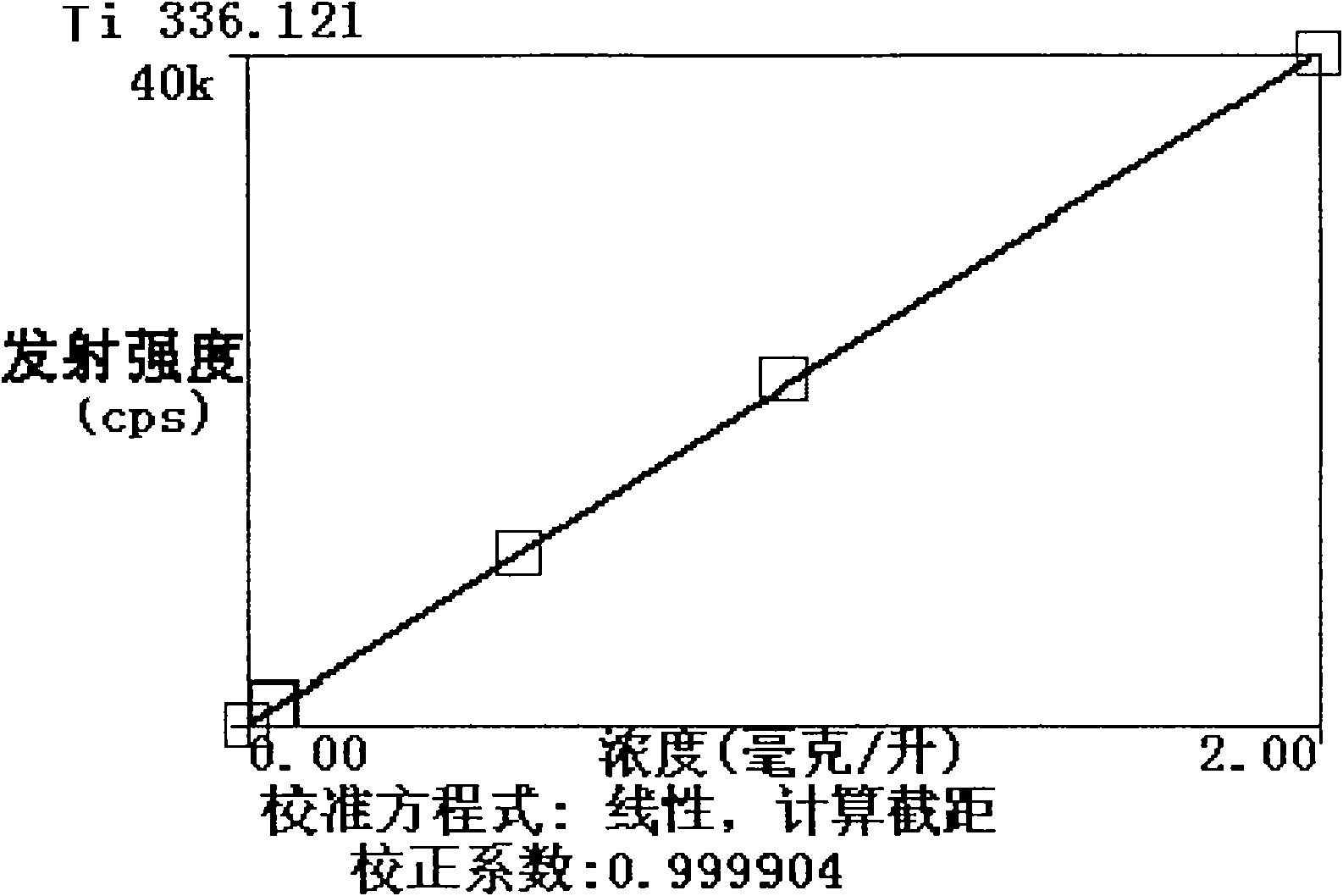

[0030] The drawing of embodiment 1 standard curve

[0031] 1. Preparation of standard solution

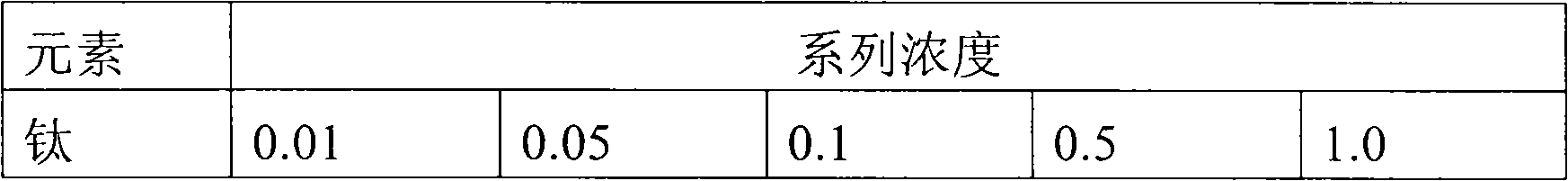

[0032] Preparation of titanium standard solution: Accurately draw the elemental standard stock solution (concentration: 1000μg / ml, single standard purchased by the National Standard Material Research Center), make the stock solution with 5% nitric acid into a 10μg / ml intermediate solution, and then take the intermediate solution Solutions Prepare a series of solutions. Accurately draw the intermediate solution according to the volume listed in Table 1 and accurately set the volume to the mark in a 50ml volumetric flask.

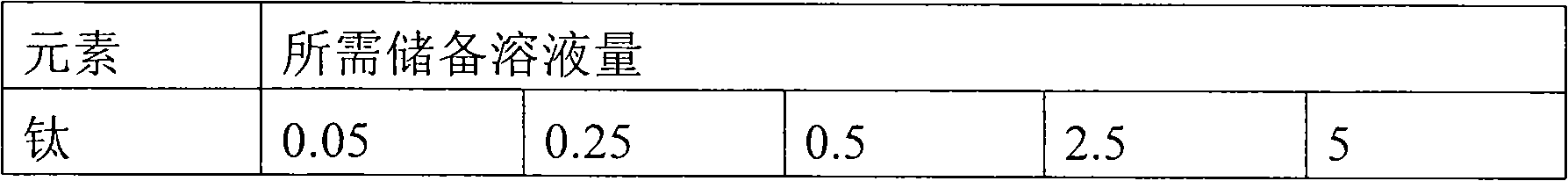

[0033] Table 1 The amount of stock solution required to prepare the standard series of solutions (unit: ml)

[0034]

[0035] 2. Reagents

[0036] (1) Preparation of 5% nitric acid

[0037] Accurately take 50ml of concentrated nitric acid (high-grade pure), put it into a beaker filled with 100ml of ultrapure water, transfer it to a 1000ml volumetric flask a...

Embodiment 2

[0062] METHODS: The OPtima5300DV inductively coupled plasma optical emission spectrometer (ICP-OES) produced by Perkin-Elmer, USA was used to determine titanium dioxide in emulsion or milk powder.

[0063] Experimental steps for detecting elements:

[0064] 1. Instrument preparation:

[0065] (1) Turn on the host and operating software, adjust the instrument to the best state, turn on the argon gas and water cooling cycle, and preheat for four hours.

[0066] 2. Sample preparation: Weigh 4.0g-5.0g of emulsion or milk powder sample, put it into a 100ml porcelain crucible, carbonize the weighed sample on a heating plate at low temperature (not boiling), and then put it into a high temperature furnace at 550°C ℃, 30min ash to remove its components, then take it out and use 1:1 (V / V) nitric acid to destroy other components, heat it to dryness at a temperature of 70-80℃, put it in a muffle furnace at 550℃, and ash again for 1h, Take it out and cool it, then transfer it to a 50ml ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com