Gasified antirust film for silver products and manufacturing method thereof

A gasification anti-rust, manufacturing method technology, applied in the direction of climate sustainability, sustainable manufacturing/processing, application, etc., can solve the problems of reducing the physical properties of the product, not suitable for degrading raw materials, etc., and achieve a simple and fast manufacturing method High efficiency, enhanced physical properties, and advanced technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

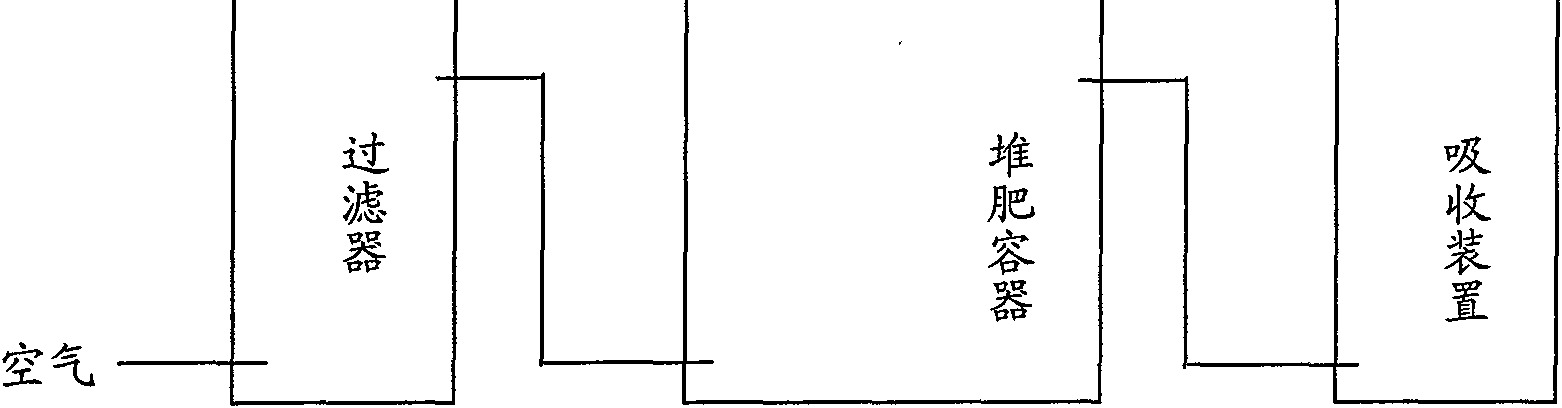

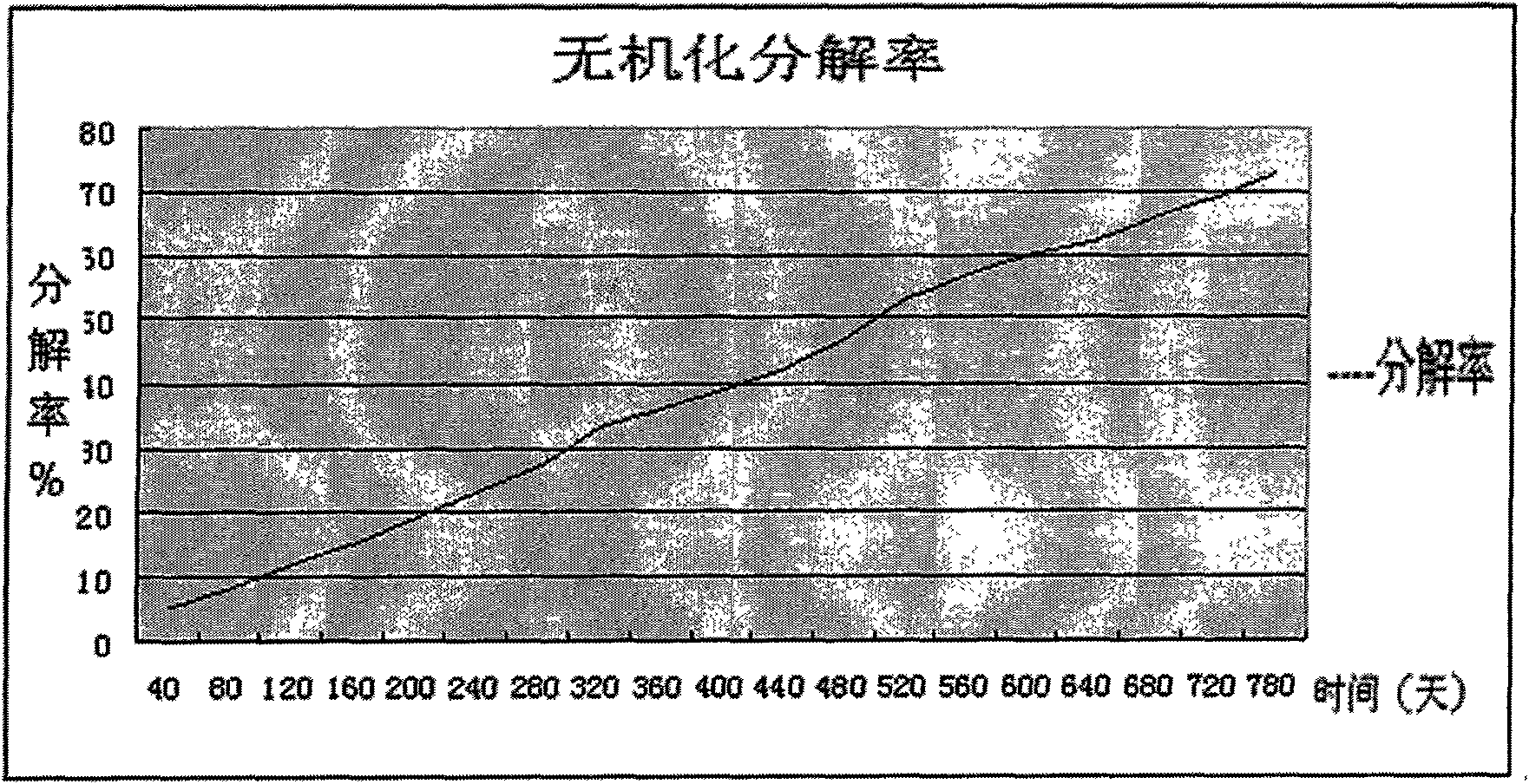

Method used

Image

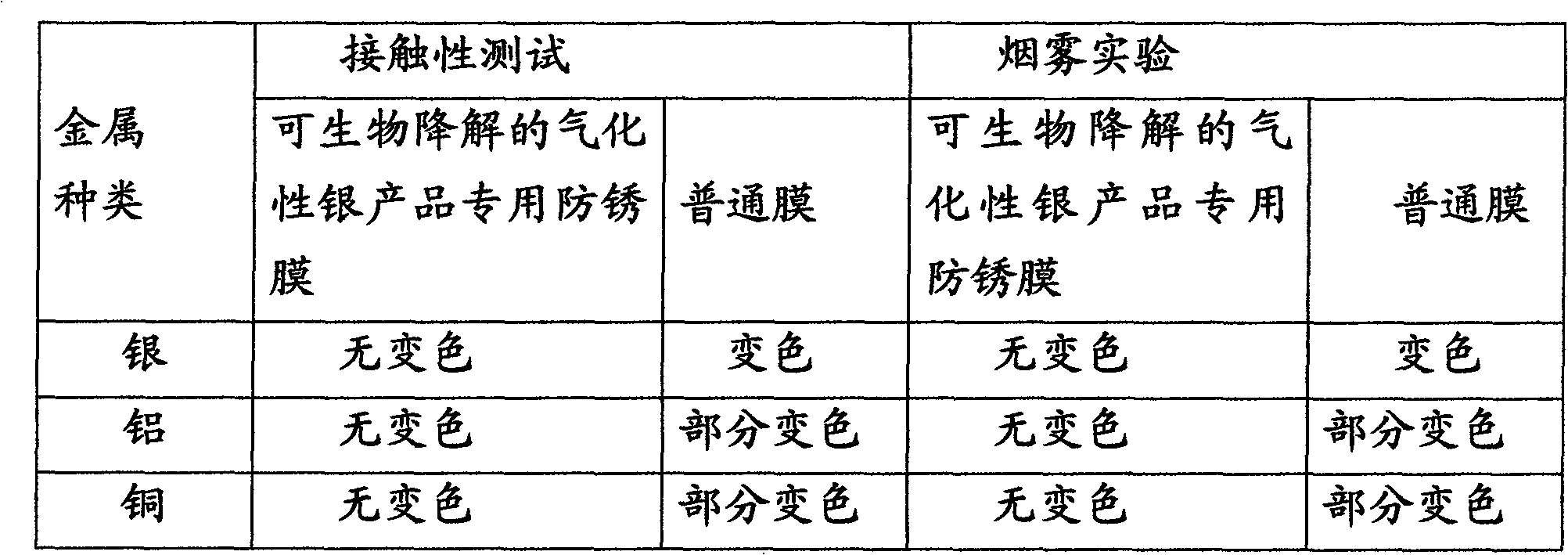

Examples

Embodiment

[0090] Raw materials, additives and dispersants for the gasification antirust film of silver products are configured according to the following ratios in parts by weight:

[0091] raw material:

[0092] Sodium benzoate (Sodium benzoate) 6 parts,

[0093] Dextrin (Dextrin) 2 parts,

[0094] Benzotriazole (Benzotriazole) 6 parts,

[0095] Tolyltriazole (Tolyltriazole) 8 parts,

[0096] Sodium molybdate (Sodium molibdate) 4 parts,

[0097] Zinc Oxide (Zinc Oxide) 2 parts,

[0098] Low density polyethylene (Low density polyethylene) 5000 parts,

[0099] Dispersant:

[0100] Hydroxy ethyl cellulose (Hydroxy ethyl cellulose) 5 parts,

[0101] Zinc stearate (zinc stearate) 7 parts,

[0102] Polyethylene wax (PE wax) 7 parts,

[0103] additive:

[0104] 100 parts of oxo-biodegradable additive masterbatch,

[0105] Metallocene paraffin polymer (METALLOCENE-OLEFIN POLYMER) 500 parts.

[0106] Among these materials, zinc stearate (zinc stearate), polyethylene wax (PE wax), an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com