Method for producing granular ammonium sulfate

A production method, ammonium sulfate technology, applied in chemical instruments and methods, ammonium salt fertilizer, inorganic chemistry, etc., can solve problems such as poor product strength, reduced S content, and nutrient deficiency, so as to save energy consumption and improve material properties , the effect of less nutrient deficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

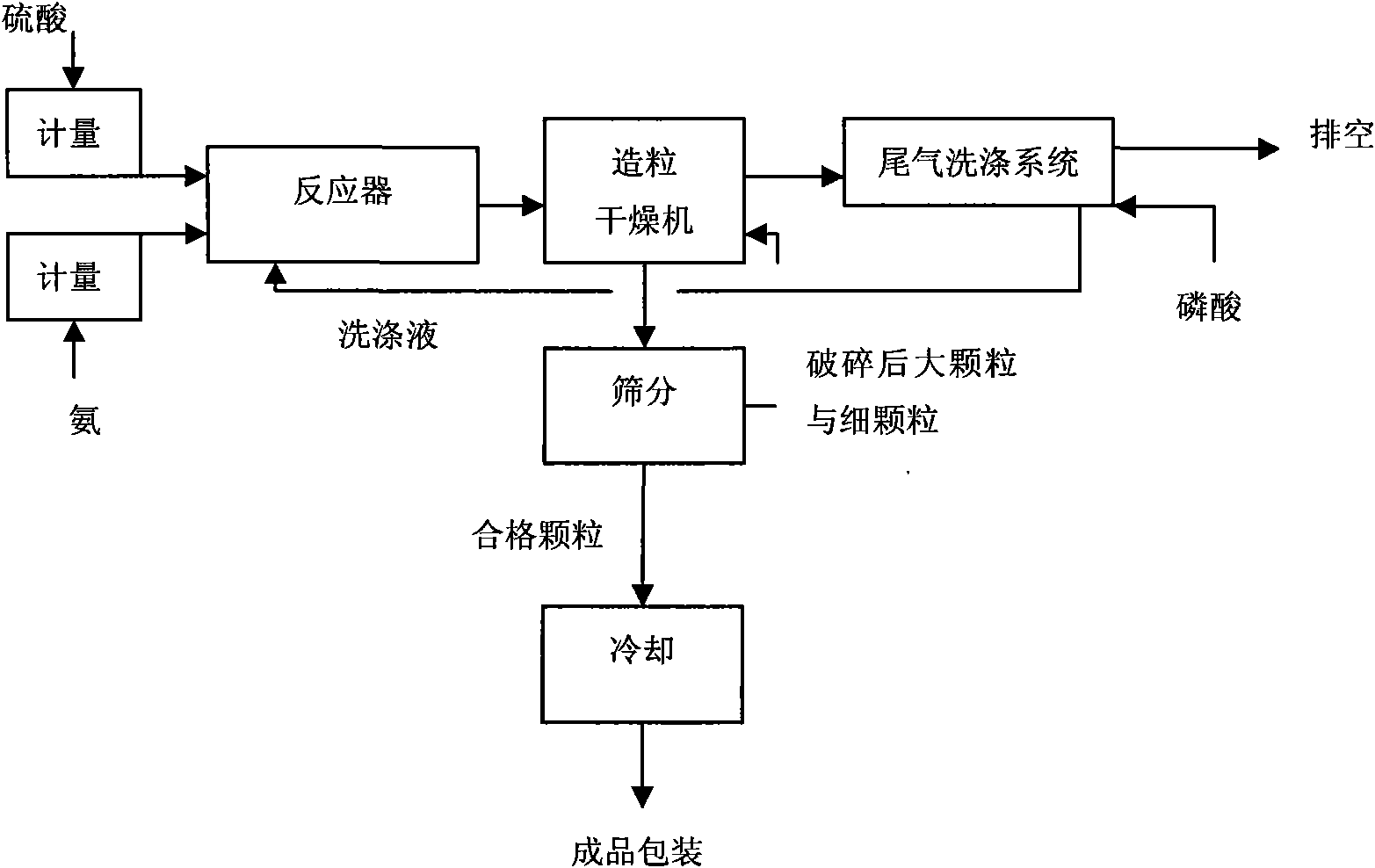

Method used

Image

Examples

Embodiment

[0019] Embodiment The Wengfu Phosphate Fertilizer Plant under Guizhou Wengfu (Group) Co., Ltd. adopts the inventive method to produce granular ammonium sulfate:

[0020] (1) Mix sulfuric acid, ammonia gas and tail gas scrubbing liquid with a mass fraction of 98% in the reactor, the mass ratio of sulfuric acid and ammonia is 8:3, and the reaction temperature is 250°C and the pressure is 0.3MPa The reaction generates high-temperature ammonium sulfate slurry;

[0021] (2) The high-temperature slurry in the previous step is sprayed on the material curtain or bed of the granulation dryer after being pressurized and atomized by the nozzle. The temperature of the material is 80°C, the moisture content of the material is 3.0% to 5.0%, and the pH value of the material is 3.5. Coating or bonding into granules at ~7.5 to obtain granular ammonium sulfate;

[0022] (3) The tail gas of the granulation dryer is sucked by the tail gas fan, and the dust is removed by the cyclone dust collecto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com