Coking wastewater advanced treatment agent and application thereof

A coking wastewater and advanced treatment technology, which is applied in the direction of oxidation water/sewage treatment, water/sewage treatment, adsorption water/sewage treatment, etc., can solve the problems of high price and complicated manufacturing process of organic polymer coagulants, and achieve reduction Effects of frictional resistance, improvement of flocculation and settlement conditions, and promotion of floc growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

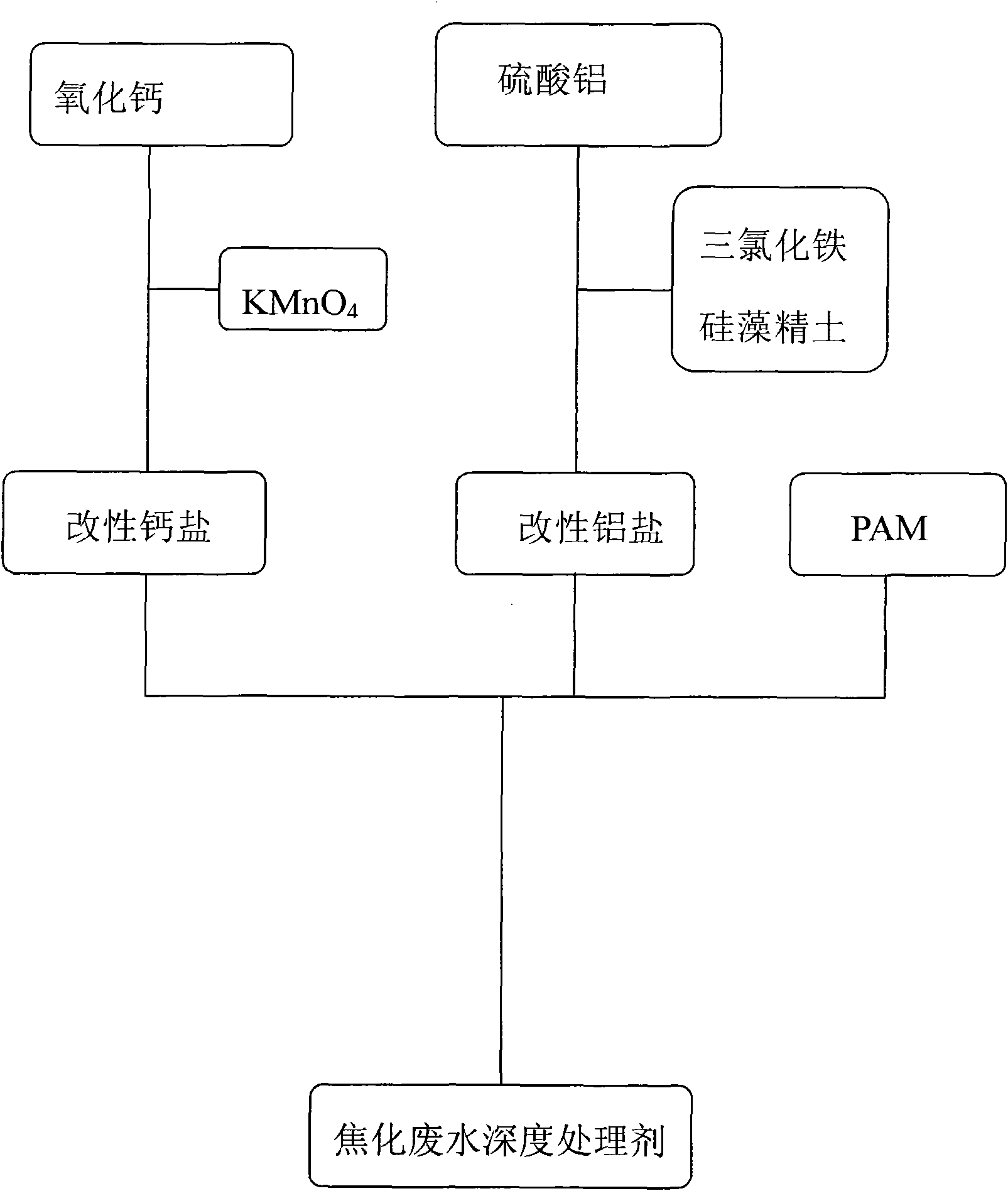

[0024] The steps of preparing coking wastewater advanced treatment agent are as follows:

[0025] First purchase industrial grade calcium oxide, potassium permanganate, aluminum sulfate, ferric chloride, diatomite (Hangzhou Zhengyang Water Treatment Company), polyacrylamide (PAM). Then measure 5000 parts by weight of CaO and 1 part by weight of KMnO 4 Mix to make modified calcium salt. Then 4 parts by weight of aluminum sulfate, 1 part by weight of ferric chloride and 1 part by weight of diatomite were mixed to prepare the modified aluminum salt. Finally, measure the modified calcium salt: modified aluminum salt: polyacrylamide = 200:400-600:1 by weight to form the coking wastewater advanced treatment agent.

Embodiment 2

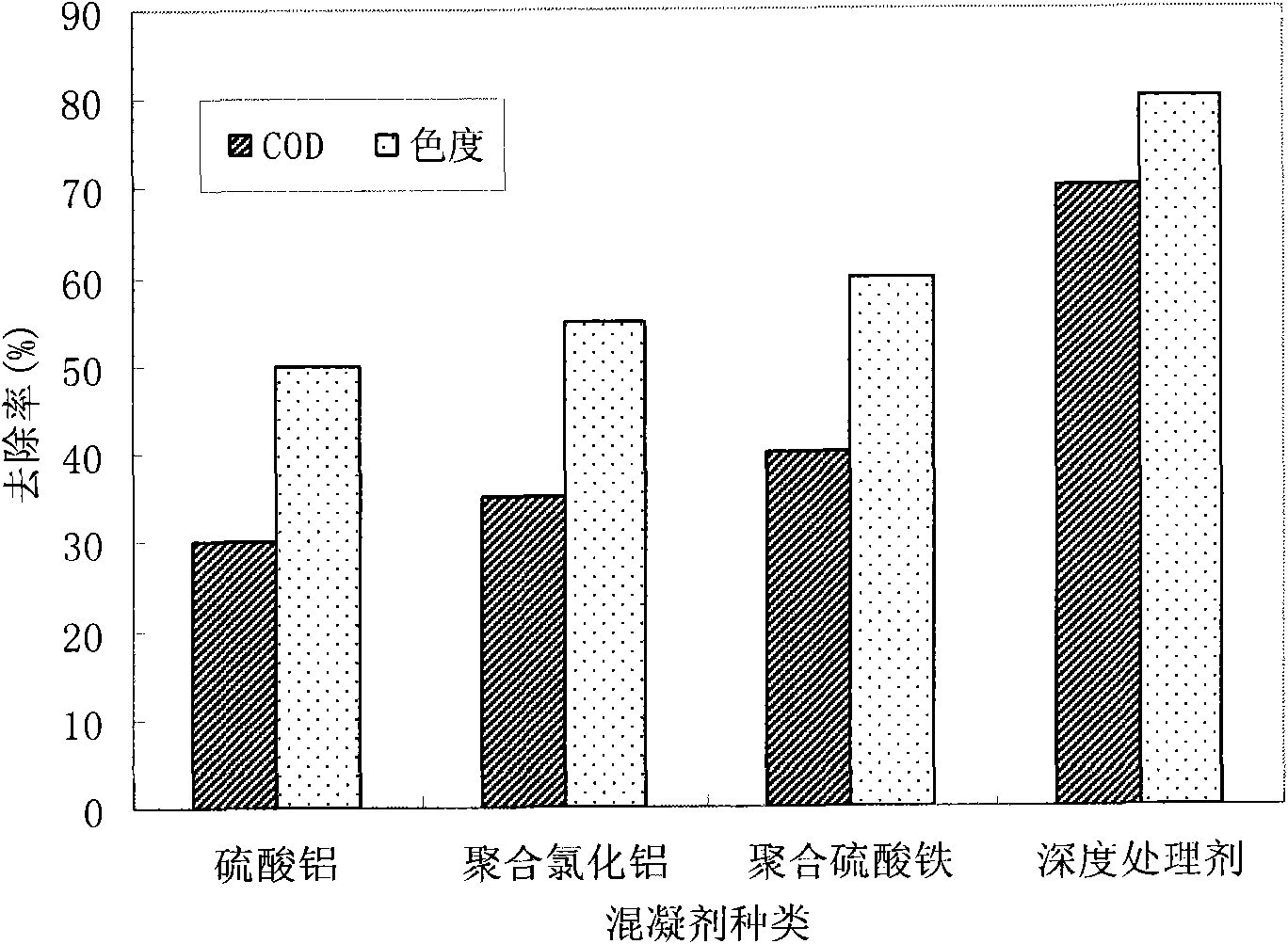

[0027] The advanced treatment agent for coking wastewater prepared in Example 1 was used for advanced treatment of coking wastewater in a coking plant, and the effect was compared with other coagulants.

[0028] Weigh 5g each of the modified calcium salt and the modified aluminum salt, add water to prepare a 5% by weight solution; weigh 0.5g of polyacrylamide, add water to prepare a 0.1‰wt% solution.

[0029] The coking wastewater from the coking plant is measured. The water quality of the coking wastewater after biochemical treatment is as follows: COD is 300-400 mg / L, and chroma is 150-250 times. Add the coking wastewater advanced treatment agent to the coking wastewater, and the dosage is modified calcium salt 100mg / L coking wastewater, modified aluminum salt 250mg / L coking wastewater, polyacrylamide 0.5mg / L coking wastewater, using enhanced coagulation. Advanced treatment (the average water temperature is 27°C, the pH of the water sample is about 7.5), and finally the COD ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com