Bifid vinegar

A technology of vinegar and bacterial strains, applied in the field of science, can solve the problems of high price of bifidofactor and increase of vinegar cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] [Example 1]: raw material vinegar method: (referring to document: Shen Longqing vinegar brewing process [J]. China brewing, 1991 (1).)

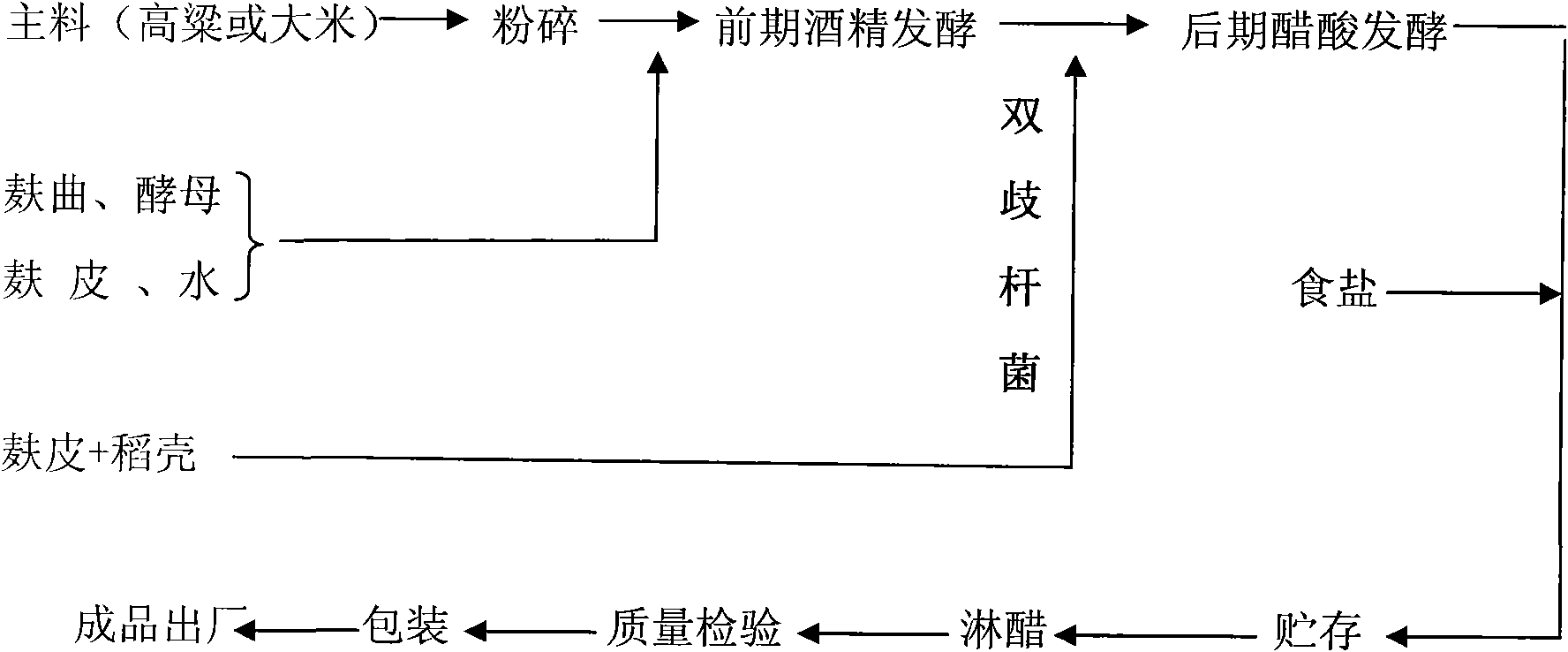

[0032] see figure 1 :

[0033] 1. Crushing the raw material (this is the prior art): the raw material is pulverized into a coarse powder, and the 40 mesh sieve passes through 100%, as evenly as possible.

[0034] 2. Alcoholic fermentation (this is the prior art); raw material is saccharified under the effect of saccharified koji and produces alcohol by the action of yeast. Based on 100 parts of main ingredients, break 50 parts of bran koji and spread it on the bottom of the pool. Spread the main ingredients on top of the bran koji, add 20 parts of bran and 10 parts of Saccharomyces cerevisiae, pour them into the production pool together, mix well, put 600-660 parts of water. Generally, the alcohol level can be measured after 5-7 days of fermentation. The general alcohol content is 5%-8%. At this time, the bran can be removed for so...

Embodiment 2

[0037] [Example 2] solid-state fermentation method: (referring to literature: Han Fenghua talks about vinegar brewing process [J], Shandong Food Fermentation, 2003 (3).)

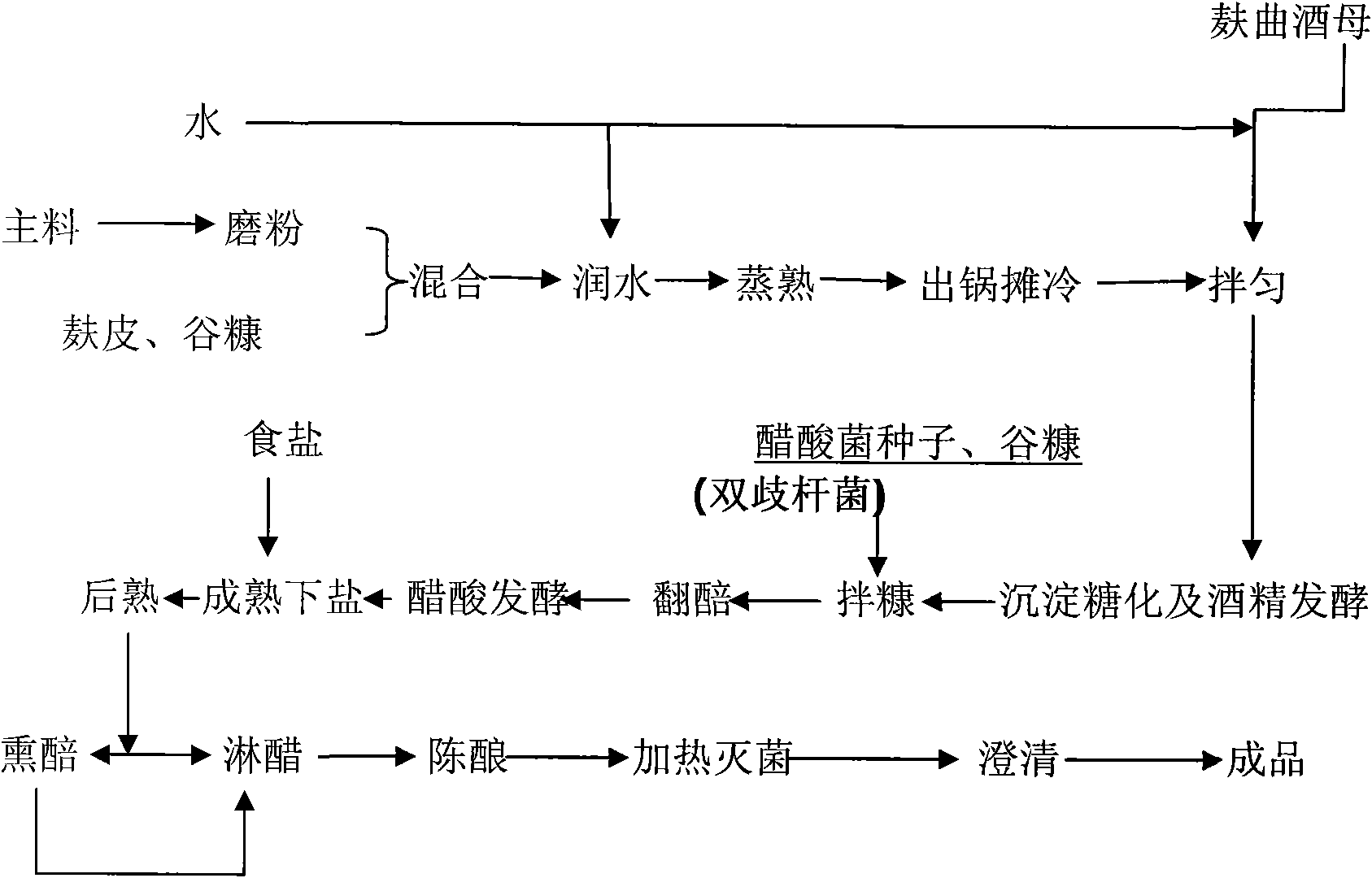

[0038] see figure 2 :

[0039] 1. Raw material processing (this is prior art)

[0040] The main ingredients used (sweet potato, millet and sorghum) are ground into fine powder, mixed with bran and rice bran, and then added with water. The amount of water added is 60% of the total amount of water. After the water is moistened, put it in a pot, wait for the water to boil into steam, then steam for 1 hour, and simmer for 1 hour. After steaming, take it out of the pan, break up the lumps or sieve them, and stir them quickly to cool down. Lower the temperature of the clinker, the lower the temperature of the material in summer, the better, generally 30-33°C, and in winter, lower the temperature to below 40°C, then add the remaining 40% of water (cold water), and add distiller's mother and crushed bran koji at...

Embodiment 3

[0045] [Example 3] Enzymatic liquefaction ventilation backflow vinegar production (referring to literature: Geng Lianyin liquid backflow vinegar production technology [J], Shandong Food Fermentation, 1994 (4).)

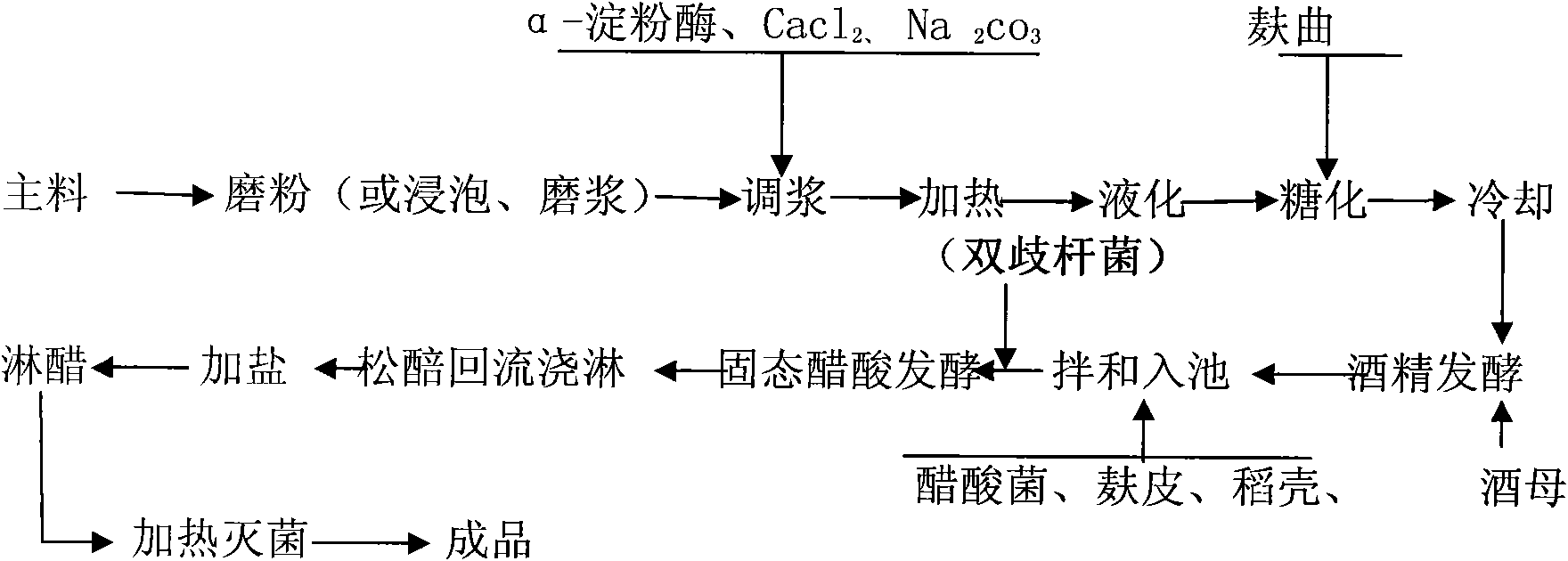

[0046] see image 3 :

[0047] 1. Acetic acid fermentation tank (this is the prior art): generally in a cylindrical shape, at the bottom 20cm apart from the pool, a false bottom is placed on the frame, generally made of bamboo. Put vinegar unstrained spirits on the top, and leave vinegar juice on the bottom. There are 12 ventilation holes with a diameter of 10cm, which are arranged symmetrically and evenly around the pool. A juice discharge valve is left at the bottom of the pool, and two vinegar storage pools are made underground. A water pump is connected to the false bottom depository, and a vinegar spray pipe is connected to the outlet of the water pump. The return liquid is pumped into the spray pipe, and the liquid is evenly poured on the surface of the vineg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com