Method for synthesizing TiCx particle enhanced nickel base composite material by reaction in-situ

A technology of particle reinforcement and composite materials, which is applied in the field of composite materials, can solve the problems of incomplete Ti-C reaction, slag, Ti, and C addition, and achieve the effect of good wettability, high hardness, and clean interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

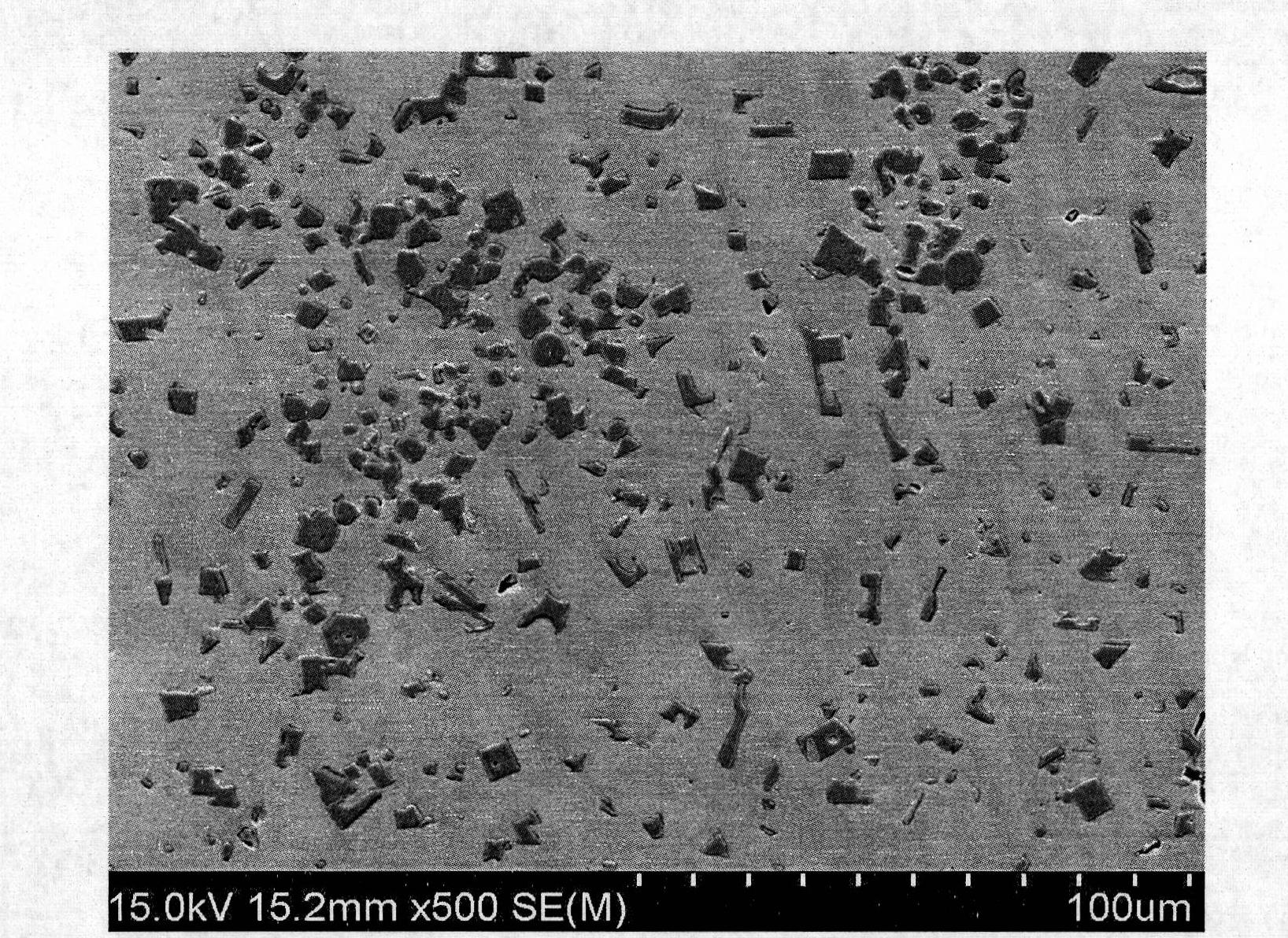

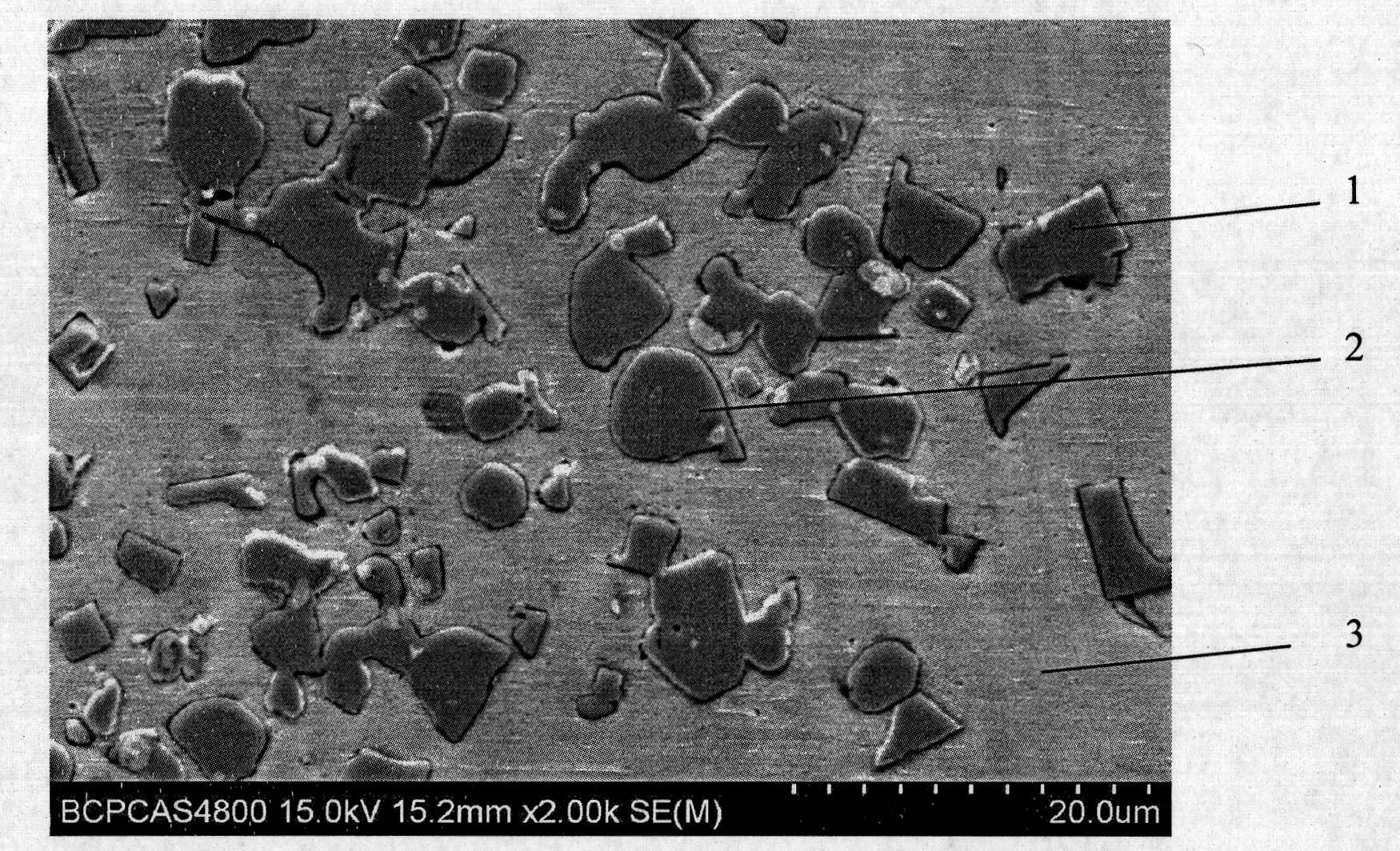

[0030] Bulk TiC was prepared as follows x / Ni composite material.

[0031] 1. Preparation of mixed powder

[0032] Use Ti, C, Al, Fe, Mo and other powder materials. Among the selected powders, Al powder (-100 mesh, purity 99.8%): 12wt.%, Fe powder (-100 mesh, purity 99.8%): 15wt.%, Mo powder (-200 mesh, purity 99.9%): 3wt.%, graphite C powder (-200 mesh, purity 99.8%): 10wt.%, the rest is Ti powder (-100 mesh, purity 99.9%).

[0033] Put the mixed powder of the above proportion into a drying oven to dry for 6 hours, then put it into a ball mill and mix for 5 hours to obtain a mixed powder with uniform composition.

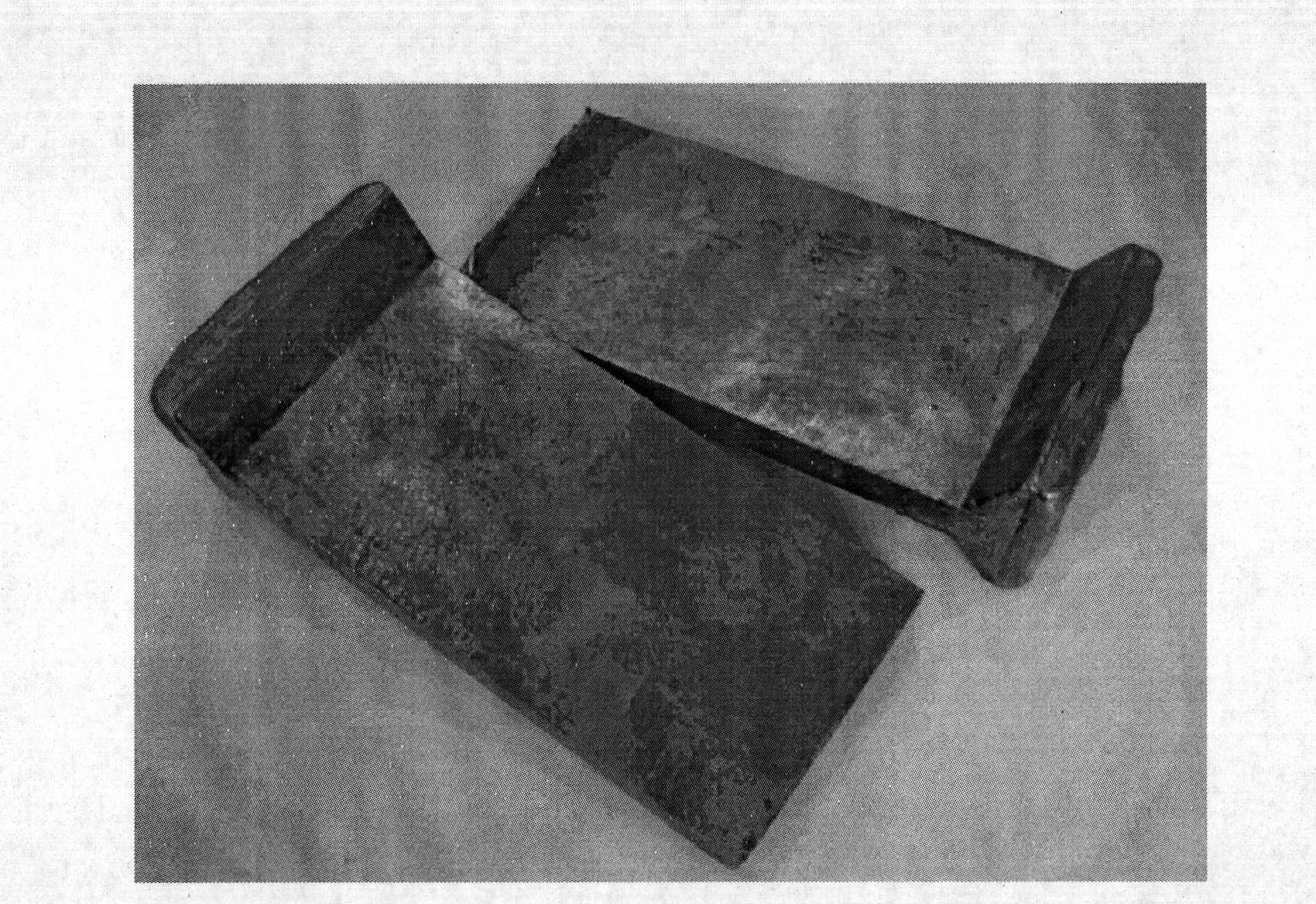

[0034] 2. Preparation of powder chips

[0035]The outer skin of the powder chip is Ni foil with a purity of 99.8%. The thickness of the Ni foil is 100 μm, the width is 70 mm, and the length is 200 mm. Roll the Ni foil into a cylinder with a diameter of about 18 mm, and pour the mixed powder mixed by ball milling described in step 1 into the cylinder, so that t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com