Preparation method of tin-oxygen-silver electric contact material

A technology of electrical contact materials, silver tin oxide, applied in the direction of circuits, electric switches, electrical components, etc., can solve the problems of uneven material structure, poor material compactness, poor processing performance, etc., and achieve shortened preparation cycle and anti-welding The effect of sex improvement and strength improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

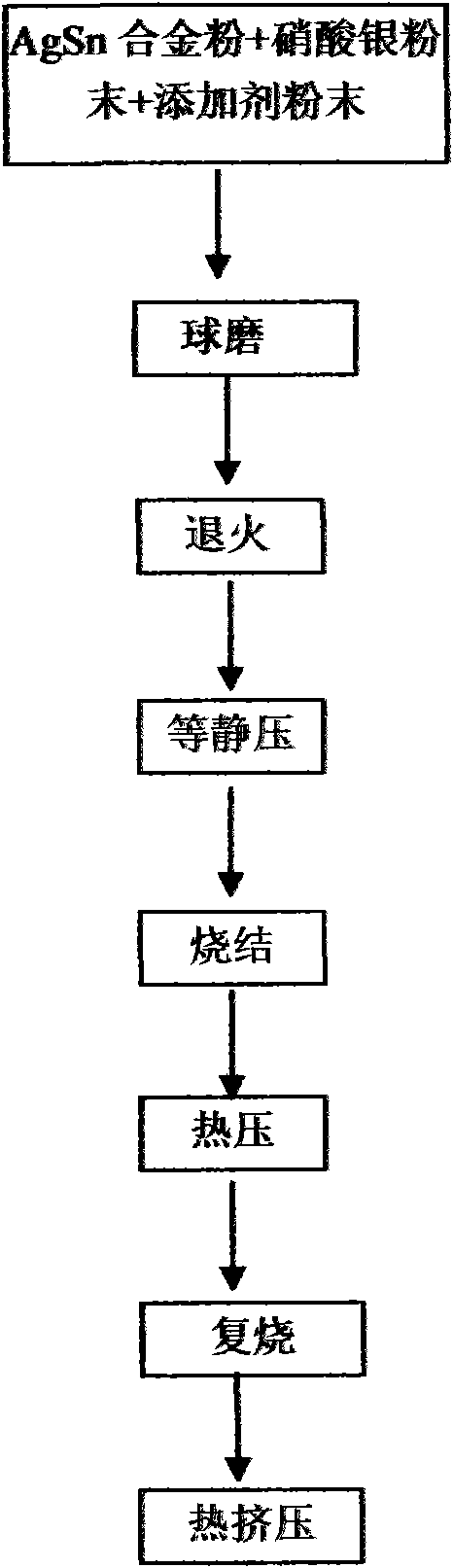

Method used

Image

Examples

Embodiment 1

[0035] 1. Put the Ag metal block and the Sn metal sheet in a medium frequency induction heating furnace to melt them into an alloy melt. At about 1050°C, use high-pressure air to forcefully impact and atomize the small flow of the above melt into powder, and the obtained AgSn Alloy powder, wherein the content of Sn is 18%, and the balance is Ag. 10kg AgSn alloy powder, 3kg silver nitrate and 130g WO after crossing 100 mesh sieve 3 Powder mixing ball milling, the ball-to-material ratio is 50:1, the ball milling speed is 500 rpm, the ball milling time is 3 hours, and the ball milling atmosphere is air;

[0036] 2. After ball milling, the powder was annealed in air at 300°C for 5 hours;

[0037] 3. Then press the annealed powder into a billet under isostatic pressure of 500MPa;

[0038] 4. Sinter the pressed body at 900°C for 2 hours in an oxygen atmosphere;

[0039] 5. Hot press the sintered body at 700MPa at 400°C for 1 minute;

[0040] 6. Then refire the hot-pressed green ...

Embodiment 2

[0044] 1. Put the Ag metal block, Sn metal sheet and Cu metal sheet in a medium-frequency induction heating furnace to melt them into an alloy melt, then cool them to obtain AgSnCu ingots, and turn the ingots to obtain AgSnCu alloy chips, in which Sn The content is 3%, and the balance is Ag. 10kg of AgSn alloy powder and 500g of silver nitrate powder passed through a 100-mesh sieve were mixed and ball-milled, the ball-to-material ratio was 1:1, the ball-milling speed was 15 revolutions, the ball-milling time was 30 hours, and the ball-milling atmosphere was air;

[0045] 2. After ball milling, the powder is annealed in air at 800°C for 1 hour;

[0046]3. Then press the annealed powder into a billet under an isostatic pressure of 100 MPa;

[0047] 4. Sinter the pressed body at 600°C for 10 hours in an oxygen atmosphere;

[0048] 5. Hot press the sintered body at 300MPa at 900°C for 30 minutes;

[0049] 6. Then refire the hot-pressed green body, that is, sinter at 600°C for 1...

Embodiment 3

[0053] 1. AgSnCu alloy powder obtained by atomization method, wherein the content of Sn is 10%, the content of Cu is 3%, and the balance is Ag. 10kgAgSnCu alloy powder, 1.5kg silver nitrate and 130gWO after passing through a 100 mesh sieve 3 Powder mixing ball milling, the ball-to-material ratio is 15:1, the ball milling speed is 150 rpm, the ball milling time is 10 hours, and the ball milling atmosphere is air;

[0054] 2. After ball milling, the powder is annealed in air at 600°C for 3 hours;

[0055] 3. Then the annealed powder is pressed into a billet under an isostatic pressure of 300MPa;

[0056] 4. Sinter the pressed body at 800°C for 5 hours in an oxygen atmosphere;

[0057] 5. Hot press the sintered green body at 500MPa at 600°C for 15 minutes;

[0058] 6. Then refire the hot-pressed green body, that is, sinter at 800°C for 5 hours in an oxygen atmosphere;

[0059] 7. Finally, hot-extrude the refired green body. The heating temperature of the hot-extruded green bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com