Manufacturing method of SOI base three-dimensional wedgy coupler integrated substrate structure

A technology of substrate structure and coupler, which is applied in the field of optoelectronics, can solve the problems affecting the coupling efficiency of coupling devices, the scattering loss cannot be ignored, and the thickness difference of three-dimensional couplers, etc., to achieve good surface quality, strong controllability, and improve coupling efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the purpose, technical solutions and advantages of the present invention clearer, to further clarify the substantive features and significant progress of the present invention. The present invention will be further described in detail below in conjunction with the accompanying drawings.

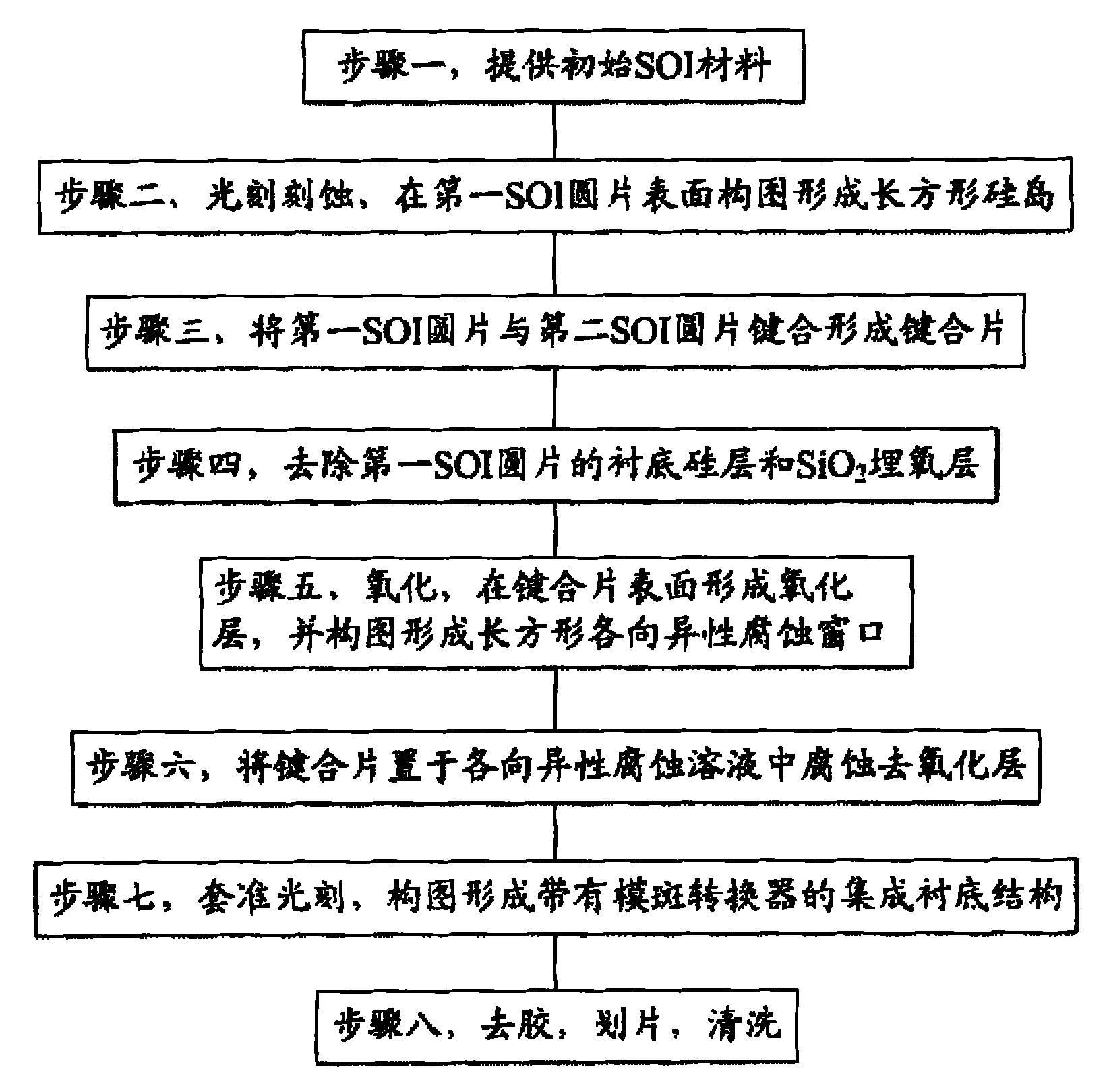

[0029] figure 2 Shown is the flow chart of the method for preparing the SOI-based three-dimensional wedge coupler integrated substrate structure provided by the present invention. Such as figure 2 As shown, the preparation method includes the following steps:

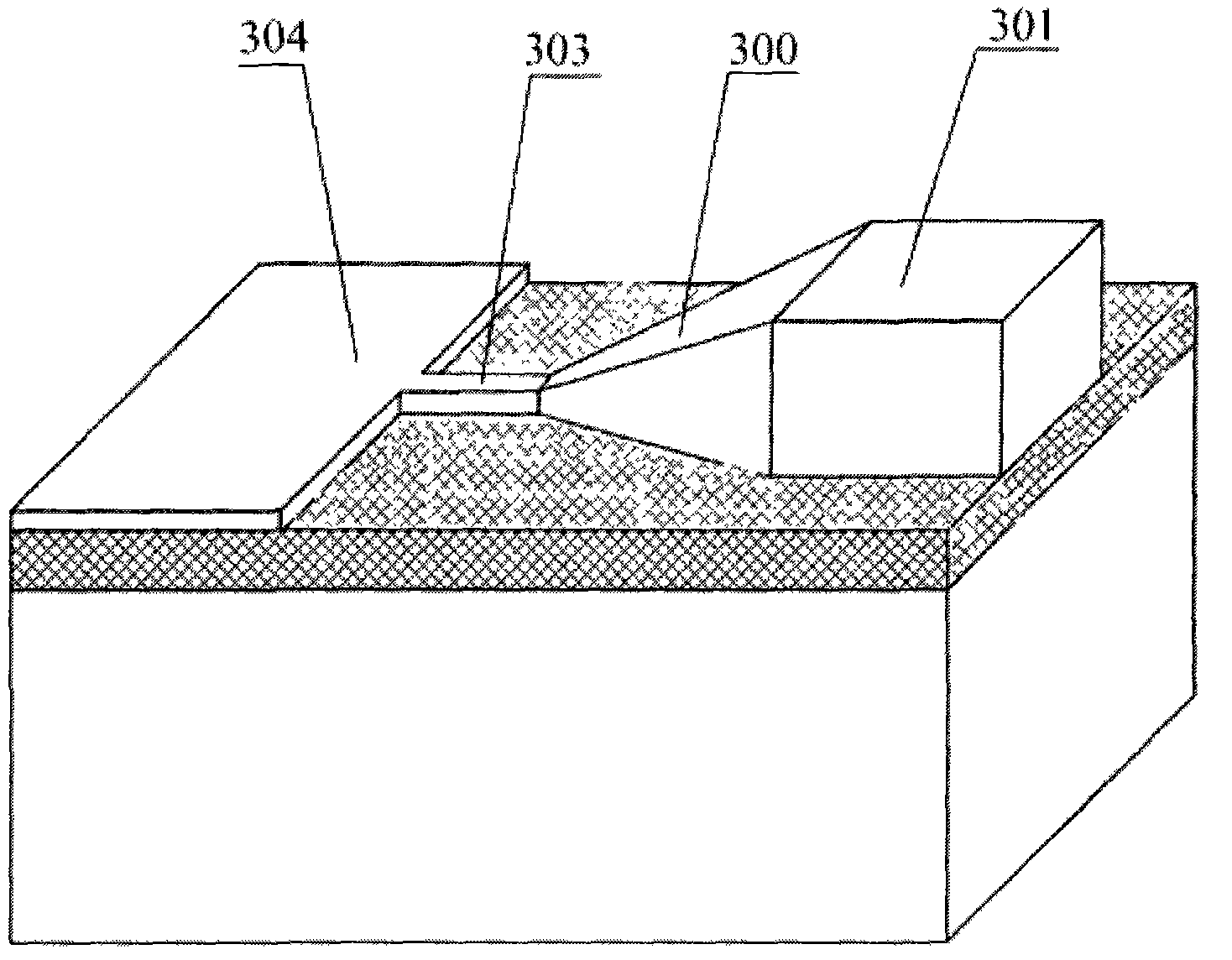

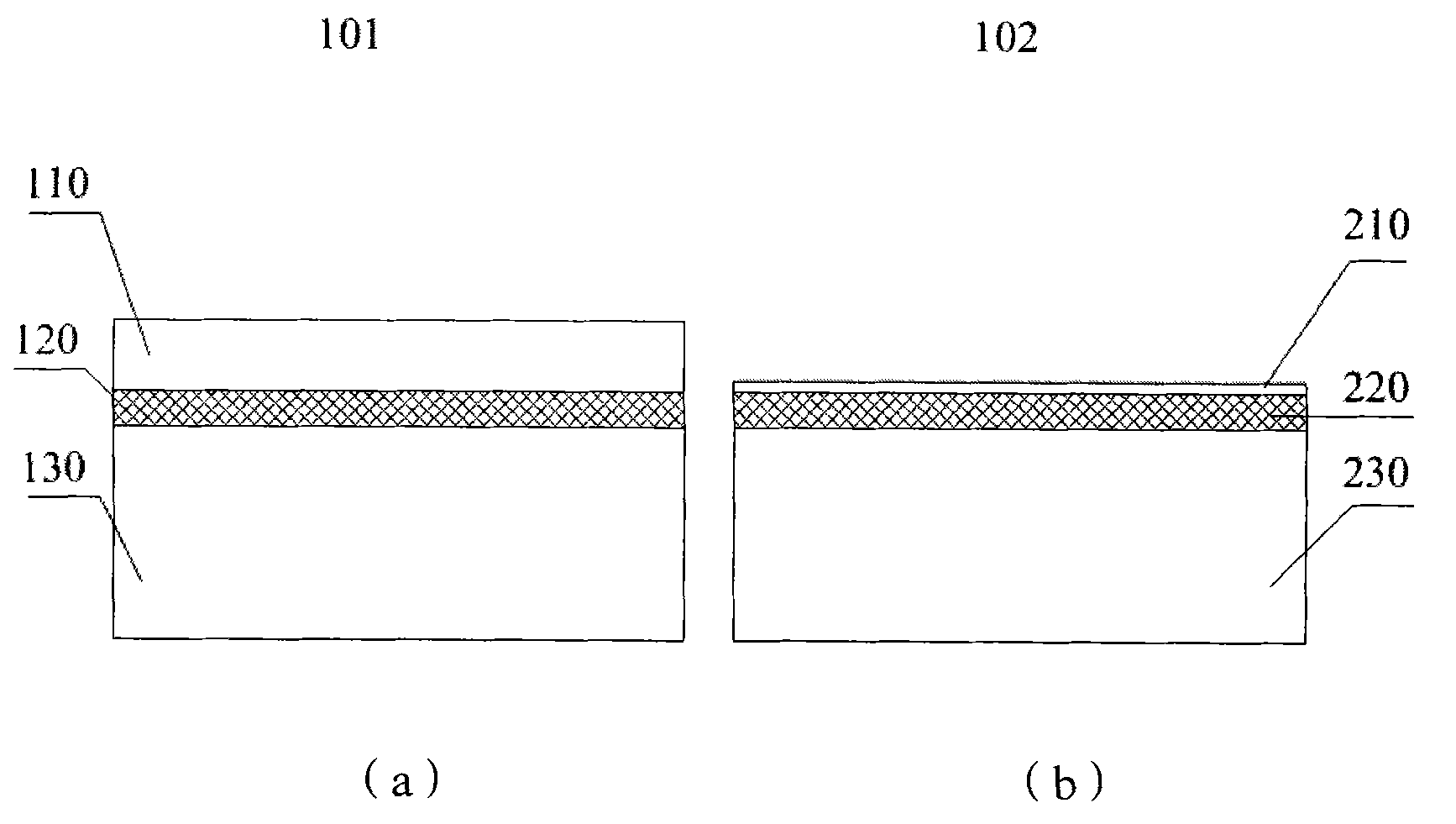

[0030] Step one, select two pieces of initial SOI material, the cross-sectional structure is as image 3 Shown.

[0031] The required initial SOI material is two pieces. The surface of the top silicon 110 of the first SOI wafer 101 is a (111) crystal plane, and the thickness is relatively thick, which is the thickness of the coupler input waveguide 301, and the thickness ranges from 3 μm to 15 μm. The crystal orien...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com