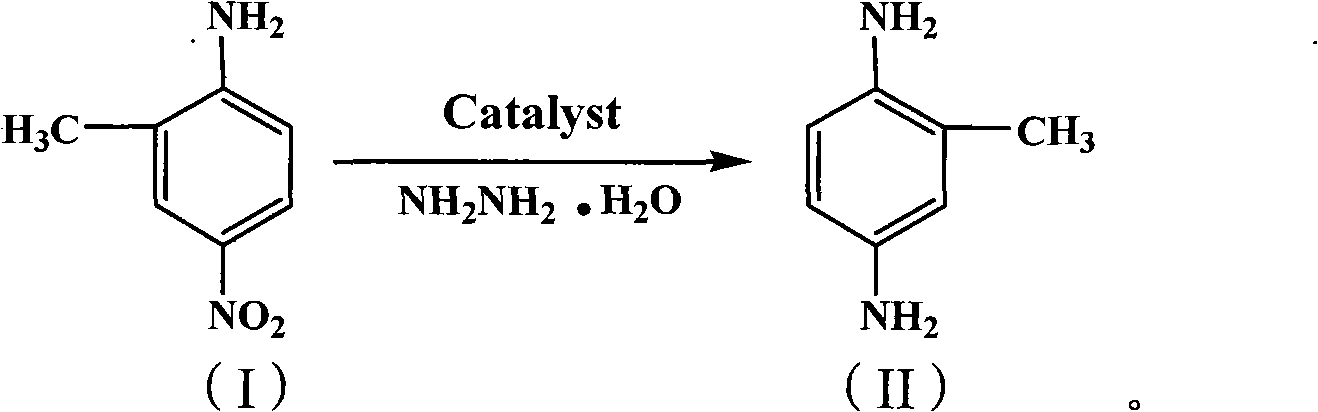

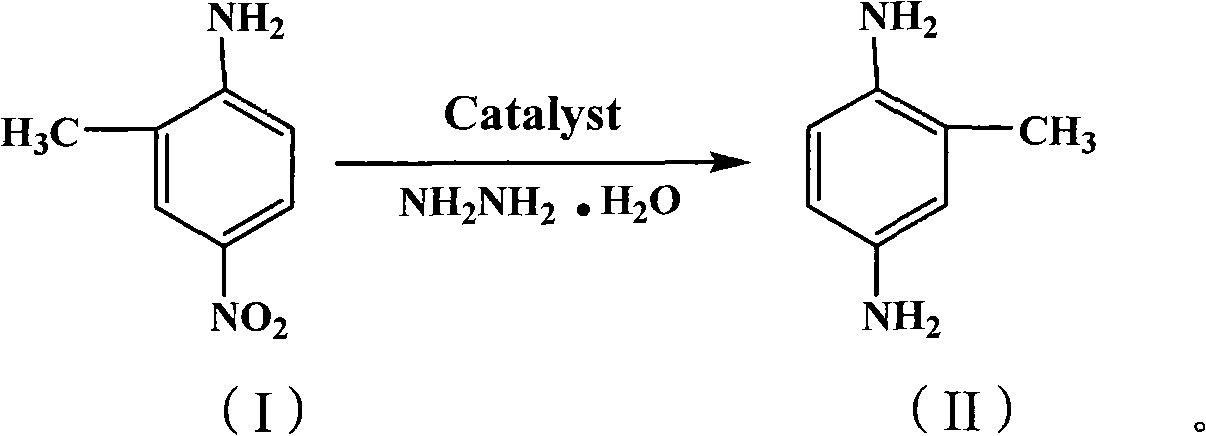

Green synthetic method of 2,5-diaminotoluene

A technology of diaminotoluene and nitroaniline, which is applied in 2 fields, can solve the problems of harsh reaction conditions, pollution of three wastes, and infrequent use, and achieve the effects of high reaction yield, low environmental pollution, and good product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] (1) Preparation of magnetic sol:

[0019] FeSO 4 ·6H 2 O, Fe 2 (SO 4 ) 3 · x H 2 O is formulated into an aqueous solution at a molar ratio of 1:2, and this solution is added to a three-neck flask, and the temperature is controlled at 338±5K, and 20% (w / w) ammonia water is added dropwise, while vigorously stirring until the pH value is 10~ 11. Continue to age at this temperature for 60 minutes after dripping to obtain an oily black precipitate. Use a magnetic field to attract and pour off the supernatant, and then wash until neutral and free of SO 4 2- (Ba 2+ inspection), spare.

[0020] (2) Synthesis of magnetic magnesium aluminum hydrotalcite:

[0021] Take a certain amount of magnetic sol and add it to a three-necked bottle, add twice distilled water, stir vigorously, control the temperature at 280±5K, take a certain amount of Mg(NO 3 ) 2 ·6H 2 O, Al(NO 3 ) 3 9H 2 O is prepared into 250 mL of nitrate aqueous solution, wherein C (Mg 2+ )+C(Al 3+ )=1.5m...

Embodiment 1

[0023] In a 500mL three-necked flask, add 152g (1 mole) of 2-methyl-4-nitroaniline, 300mL of ethanol, and 7.6g (5%) of a magnetic magnesium-aluminum hydrotalcite solid base catalyst, stir, and heat to make p-chloronitrate Dissolve benzene, raise the temperature to 50°C, slowly add hydrazine hydrate 96g (3 moles) dropwise for 1 hour, keep warm (50°C) and react for 5 hours, filter while it is hot, take the filtrate and add 500mL of water to make the solution alkaline , cooled to below 0°C, left standing, white crystals were precipitated, filtered and dried to obtain 98 g of 2,5-diaminotoluene with a yield of 80%.

[0024] The melting point of the product is >300°C. The purity is 98% (HPLC analysis conditions: chromatographic column C18, Φ4.0×200mm, column temperature 30°C, mobile phase 30% methanol-70% 0.02M phosphate buffer). IR(KBr)cm -1 : 3045, 2880, 2610, 2090, 1605, 1555, 1510, 1168, 1145, 1010, 822, 850.

Embodiment 2

[0026] In a 500mL three-necked flask, add 152g (1 mole) of 2-methyl-4-nitroaniline, 300mL of ethanol, and 1.5g (1%) of a magnetic magnesium-aluminum hydrotalcite solid base catalyst, stir and heat to make p-chloronitrate Dissolve benzene, raise the temperature to 100°C, slowly add 64g (2 moles) of hydrazine hydrate dropwise for 1 hour, keep warm (100°C) and react for 10 hours, filter while it is hot, take the filtrate and add 500mL of water to make the solution alkaline , cooled to below 0° C., left standing, white crystals were precipitated, filtered and dried to obtain 85 g of 2,5-diaminotoluene with a yield of 70%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com