Organic molybdenum complex compound, preparation method and application thereof

A technology of organic molybdenum and complexes, applied in organic molybdenum complexes, the application of the organic molybdenum complexes in the synthesis of polydicyclopentadiene, the preparation field of the organic molybdenum complexes, can solve the synthesis conditions Harsh, difficult to popularize and apply, low cost and other issues, to achieve the effect of low cost, high chemical stability and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

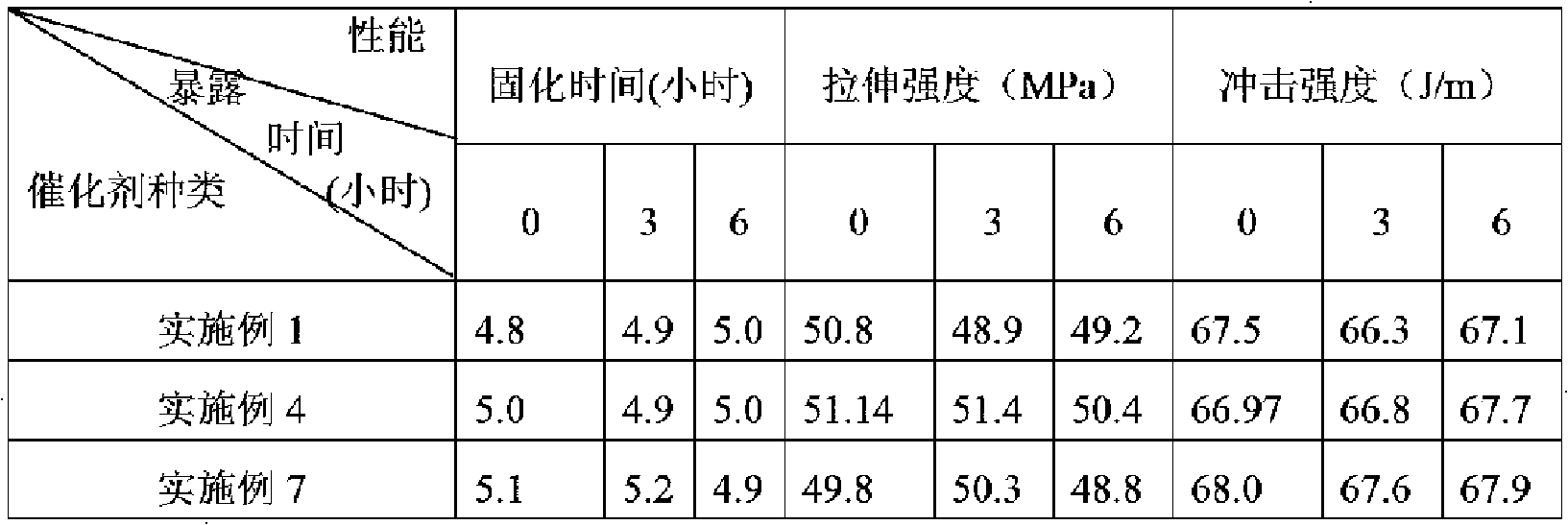

Examples

Embodiment 1

[0037] The organic molybdenum complex of this embodiment is [MoO 2 (NPh 3 ) 2 ]Cl 2 .

[0038] The preparation method of the organomolybdenum complex of the present embodiment is as follows:

[0039] Weigh 6g of molybdic acid (H 2 MoO 4 ), add 21ml of concentrated hydrochloric acid under constant stirring at 50°C, increase the temperature and reflux until clarified, then cool down to 40°C to obtain a hydrochloric acid solution of molybdic acid;

[0040] Weigh 18.15g of triphenylamine, add 181ml of ethanol and stir to dissolve, then slowly add it dropwise into the above-mentioned hydrochloric acid solution of molybdic acid at 40°C under vigorous stirring, a precipitate is formed, and then continue to stir for 6 hours, and then filter the precipitate with suction The cake was washed three times with acetone and then three times with ether, and the washed filter cake was vacuum-dried at 50° C. for 8 hours to obtain 17.4 g of organic molybdenum complex.

Embodiment 2

[0042] The organic molybdenum complex of the present embodiment is {MoO 2 [N(PhC 4 h 9 ) 3 ] 2} Cl 2 .

[0043] The preparation method of the organomolybdenum complex of the present embodiment is as follows:

[0044] Weigh 6g of molybdic acid (H 2 MoO 4 ), add 21ml of concentrated hydrochloric acid under constant stirring at 40°C, increase the temperature and reflux until clarified, then cool down to 40°C to obtain a hydrochloric acid solution of molybdic acid;

[0045] Weigh 24.6g of tris(4-n-butylphenyl)amine, add 126ml of ethanol and stir to dissolve, then slowly add dropwise to the above-mentioned hydrochloric acid solution of molybdic acid at 40°C under vigorous stirring, a precipitate is formed, and then continue to stir for 6 After the precipitate was suction filtered, the filter cake was washed three times with acetone and then three times with ether, and the washed filter cake was vacuum-dried at 60° C. for 8 hours to obtain 23.3 g of an organic molybdenum com...

Embodiment 3

[0047] The organic molybdenum complex of this embodiment is [MoO 2 (PPh 3 ) 2 ]Cl 2 .

[0048] The preparation method of the organomolybdenum complex of the present embodiment is as follows:

[0049] Weigh 6g of molybdic acid (H 2 MoO 4 ), add 21ml of concentrated hydrochloric acid under constant stirring at 80°C, increase the temperature and reflux until clarified, then cool down to 40°C to obtain a hydrochloric acid solution of molybdic acid;

[0050] Weigh 19.43g of triphenylphosphine, add 65ml of ethanol and stir to dissolve, then slowly add dropwise to the above-mentioned hydrochloric acid solution of molybdic acid at 40°C under vigorous stirring, a precipitate is formed, and then continue to stir for 5 hours, and then filter the precipitate with suction The cake was washed three times with acetone and then three times with ether, and the washed filter cake was vacuum-dried at 80° C. for 8 hours to obtain 22.1 g of organic molybdenum complex.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com