Multi-doping zinc-oxide-base wide-bandgap conducting material and preparation method thereof

A conductive material, zinc oxide-based technology, applied in the direction of conductive materials, conductive materials, cable/conductor manufacturing, etc., can solve problems such as easy performance degradation, unsatisfactory application, poor stability of single-doped zinc oxide-based films, etc. Achieve the effect of high transparent conductivity, high stability and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

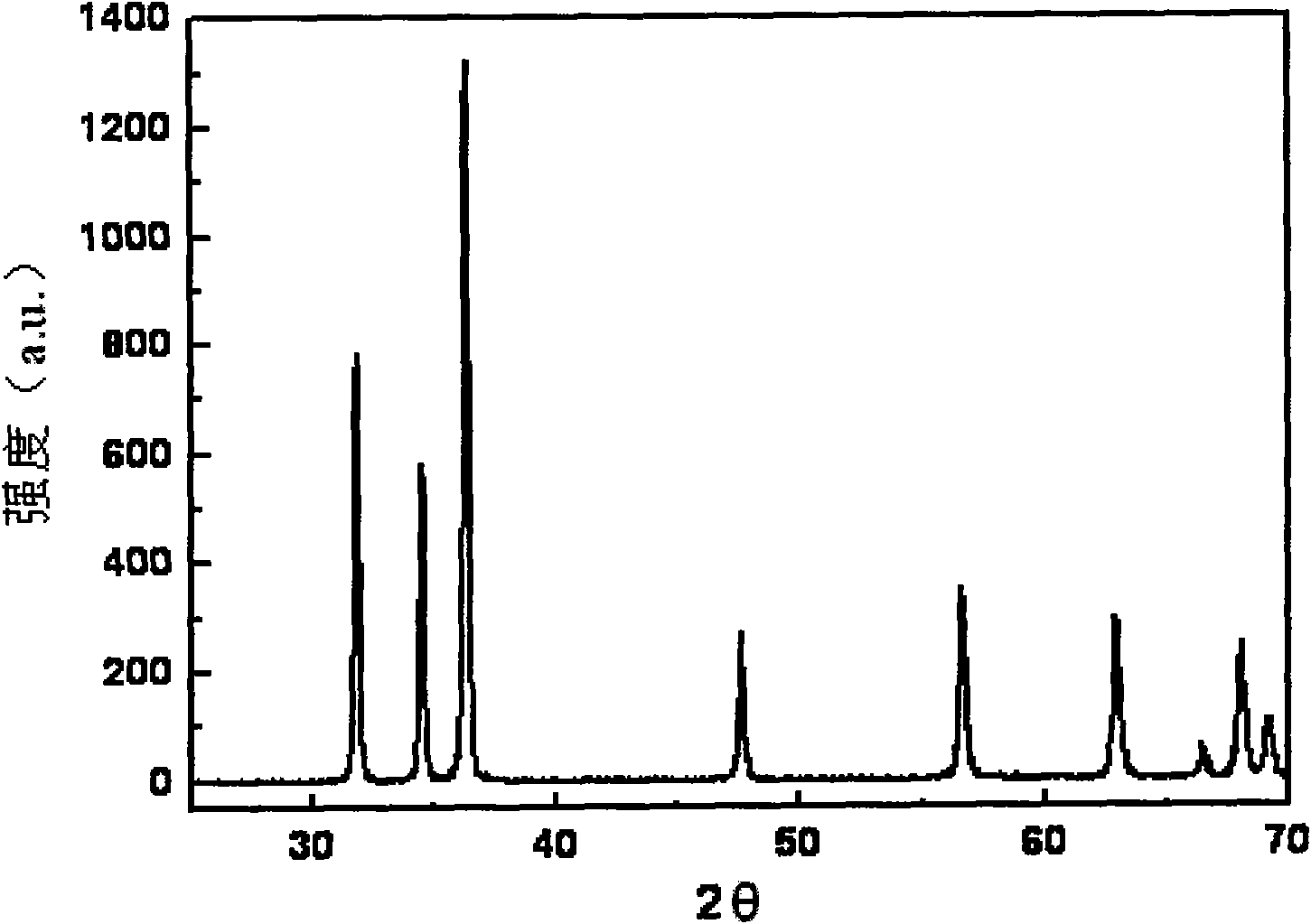

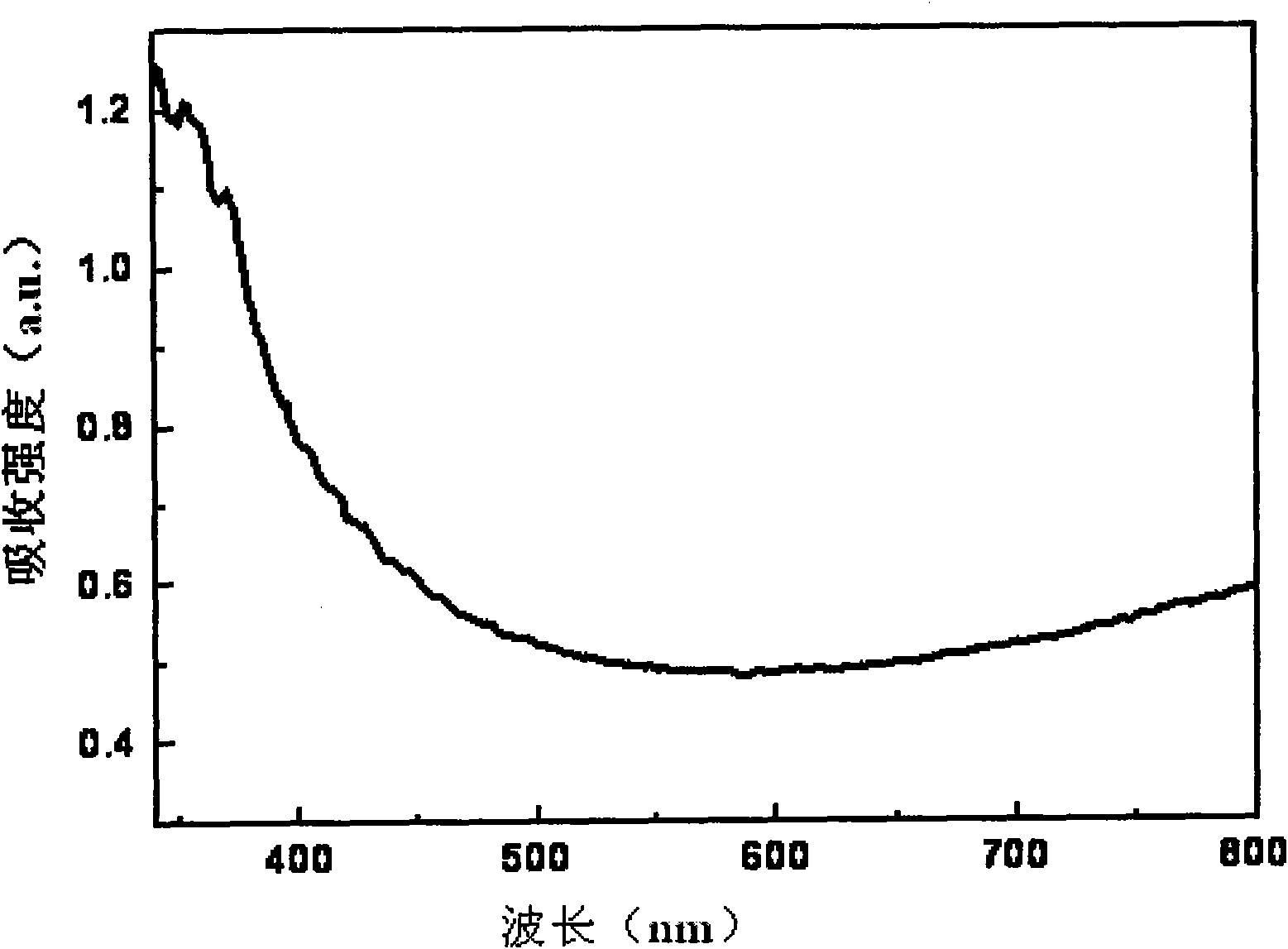

[0031]A preparation method of a multi-element doped zinc oxide (ZnO) wide bandgap conductive material, using zinc oxide, aluminum oxide and tin dioxide as raw materials, and the doping ratios of Al and Sn in terms of Zn are 2.0mol% and 1.0% respectively mol%, uniform ball milling and mixing for 20 hours to obtain the precursor doped powder, then pre-calcined at 900°C for 24 hours to obtain the doped powder, and finally compression molded and sintered at 1400°C for 4 hours to prepare ZnO:Al, Sn wide forbidden With conductive ceramic material. The material is 98% relative to the theoretical density, figure 1 It is the XRD spectrum of the ZnO:Al, Sn wide bandgap conductive ceramic material prepared in this embodiment, and the sample tested by XRD is a ZnO ceramic phase. figure 2 For the ZnO that makes in the present embodiment: Al, the absorption spectrum of Sn wide bandgap conductive ceramic material, illustrate that Al and Sn have been mixed in the ZnO lattice, have changed t...

Embodiment 2

[0035] A preparation method of a multi-element doped zinc oxide wide bandgap conductive material, using zinc oxide, aluminum hydroxide and ammonium tungstate as raw materials, and the doping ratios of Al and W based on Zn are 3.0 mol% and 0.25 mol% respectively , uniformly ball milled and mixed for 2 hours to obtain the precursor doped powder, then pre-fired at 800°C for 6 hours to obtain the doped powder, and finally compression molded and sintered at 1350°C for 12 hours to prepare ZnO:Al, W wide bandgap conductive Ceramic material.

[0036] Using the multi-element-doped zinc oxide wide-bandgap conductive material prepared in this example by high vacuum magnetron sputtering, the ZnO-based transparent conductive film has high visible light transmittance, and the temperature is 60 degrees Celsius 1. Accelerated aging for 50 hours in an environment with a relative humidity of 70% has a higher retention rate of more than 95% in electrical conductivity and light transmittance, and...

Embodiment 3

[0038] A preparation method of a multi-element doped zinc oxide wide bandgap conductive material, using zinc oxide, boric acid, aluminum hydroxide and gallium oxide as raw materials, and the doping ratios of B, Al and Ga are respectively 1.0 mol % and 1.0 mol % based on Zn. 3.0mol% and 0.25mol%, uniform ball milling and mixing for 2 hours to obtain a precursor doped powder, then pre-calcined at 800°C for 6 hours to obtain a doped powder, and finally compression molded and sintered at 1350°C for 12 hours to prepare ZnO: B, Al, Ga wide bandgap conductive ceramic material.

[0039] Using the multi-element-doped zinc oxide wide-bandgap conductive material prepared in this example by high vacuum magnetron sputtering, the ZnO-based transparent conductive film has high visible light transmittance, and the temperature is 60 degrees Celsius 1. Accelerated aging for 50 hours in an environment with a relative humidity of 70% has a higher retention rate of more than 95% in electrical cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com