Adsorption concentration method and device of volatile organic matter in solution

A technology of organic matter and solution, applied in separation methods, chemical instruments and methods, solid adsorbent liquid separation, etc., can solve the problems of high one-time investment, high equipment requirements, easy membrane clogging, etc., and achieve low equipment one-time investment, Simple process and energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

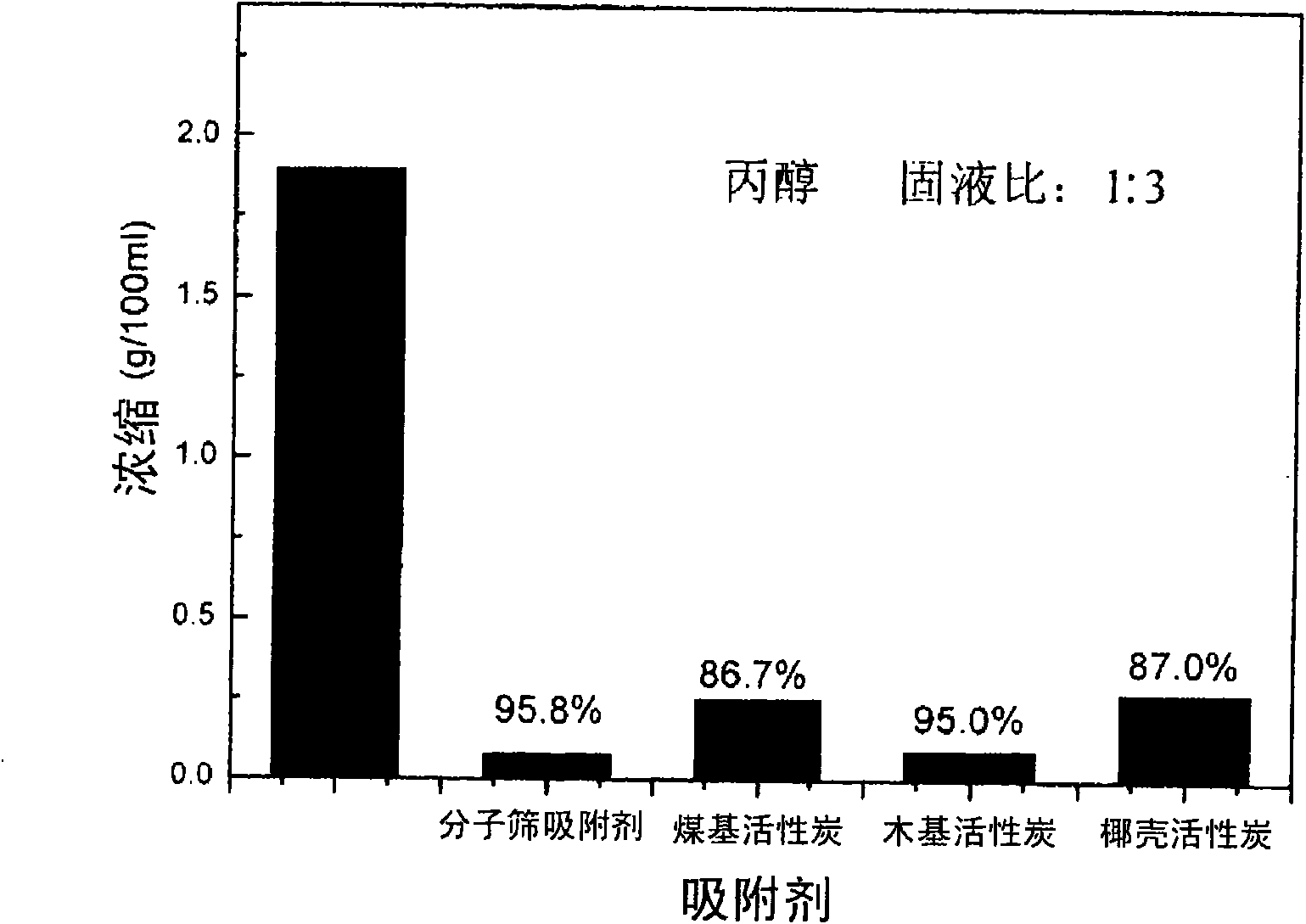

[0053] Take 1.863g / L propanol solution, for different adsorbents, carry out static adsorption according to the amount of solid-liquid mass ratio of 1:3, after reaching the adsorption equilibrium, use gas chromatography to quantitatively analyze the adsorption process, the molecular sieve adsorption rate reaches 95.8 %, coal-based activated carbon adsorption rate reached 86.7%, wood-based activated carbon was 95.0%, coconut shell-based activated carbon was 87.0% (such as figure 2 ).

Embodiment 2

[0055] Take 1.863g / L propanol solution, for hydrophobic molecular sieve and wood-based activated carbon adsorbent, carry out static adsorption according to the amount of solid-liquid mass ratio of 1:6, adjust the pH value of the reaction system, and use gas chromatography to analyze the adsorption after reaching adsorption equilibrium. Quantitative analysis of the process shows that the molecular sieve adsorption rate reaches 89.6% at pH=3, the wood-based activated carbon is 95.8%, the adsorption rate reaches 83.5% at pH=11, and the wood-based activated carbon is 96.8%.

Embodiment 3

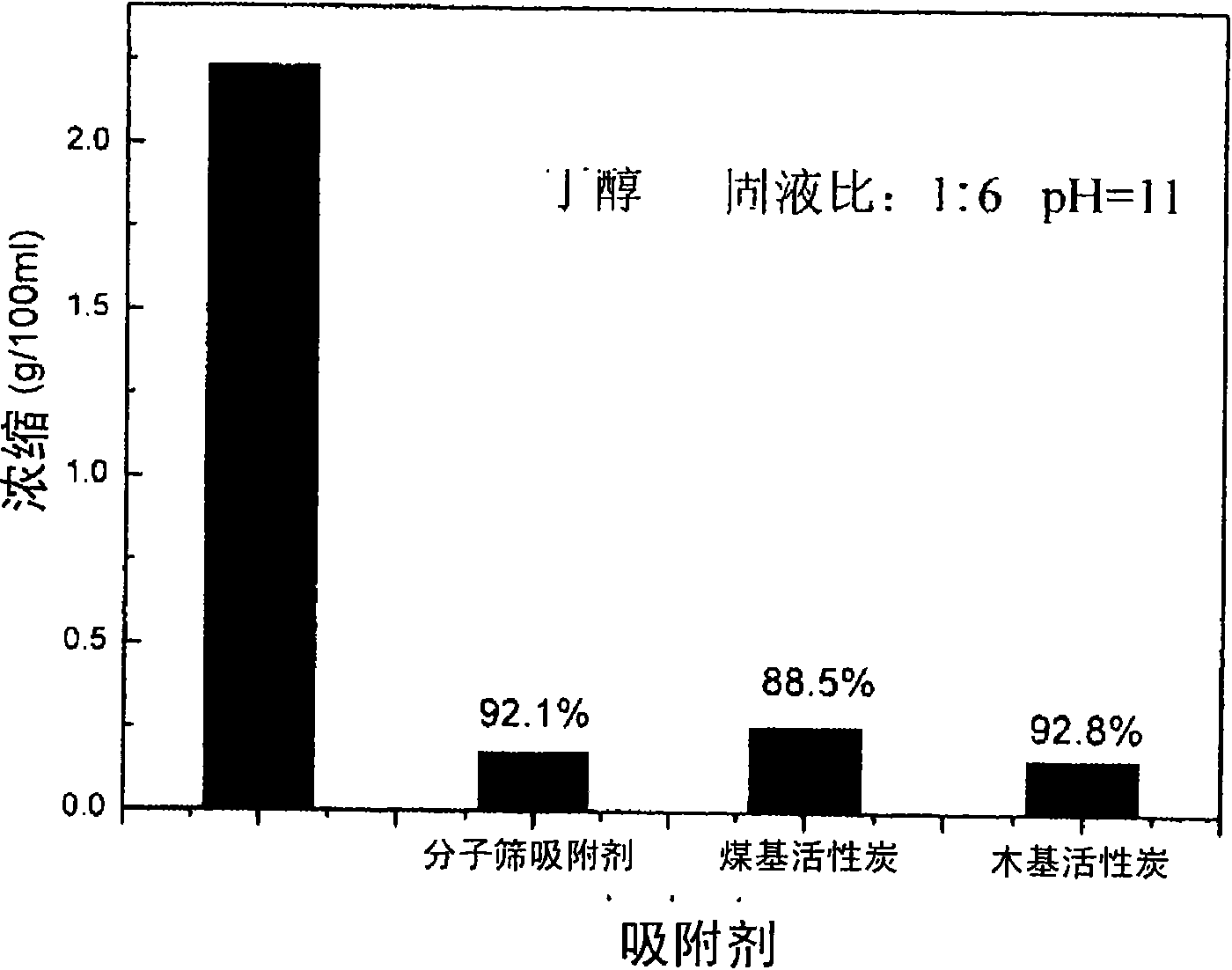

[0057] Take 2.0013g / L butanol solution, for different adsorbents, carry out static adsorption according to the amount of solid-liquid mass ratio of 1:6, after reaching the adsorption equilibrium, use gas chromatography to quantitatively analyze the adsorption process, the molecular sieve adsorption rate reaches 92.1 %, the adsorption capacity reached 12.1%; the coal-based activated carbon adsorption rate reached 88.5%, and the adsorption capacity reached 11.6%; the wood-based activated carbon was 92.8%, and the adsorption capacity was 12.8% (such as image 3 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com