Method for eliminating volatile organic compounds such as formaldehyde and benzene in furniture

A technology for organic matter and furniture, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of secondary pollution, long time, inability to use multiple times, etc., and achieve the effect of good safety and strong pertinence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

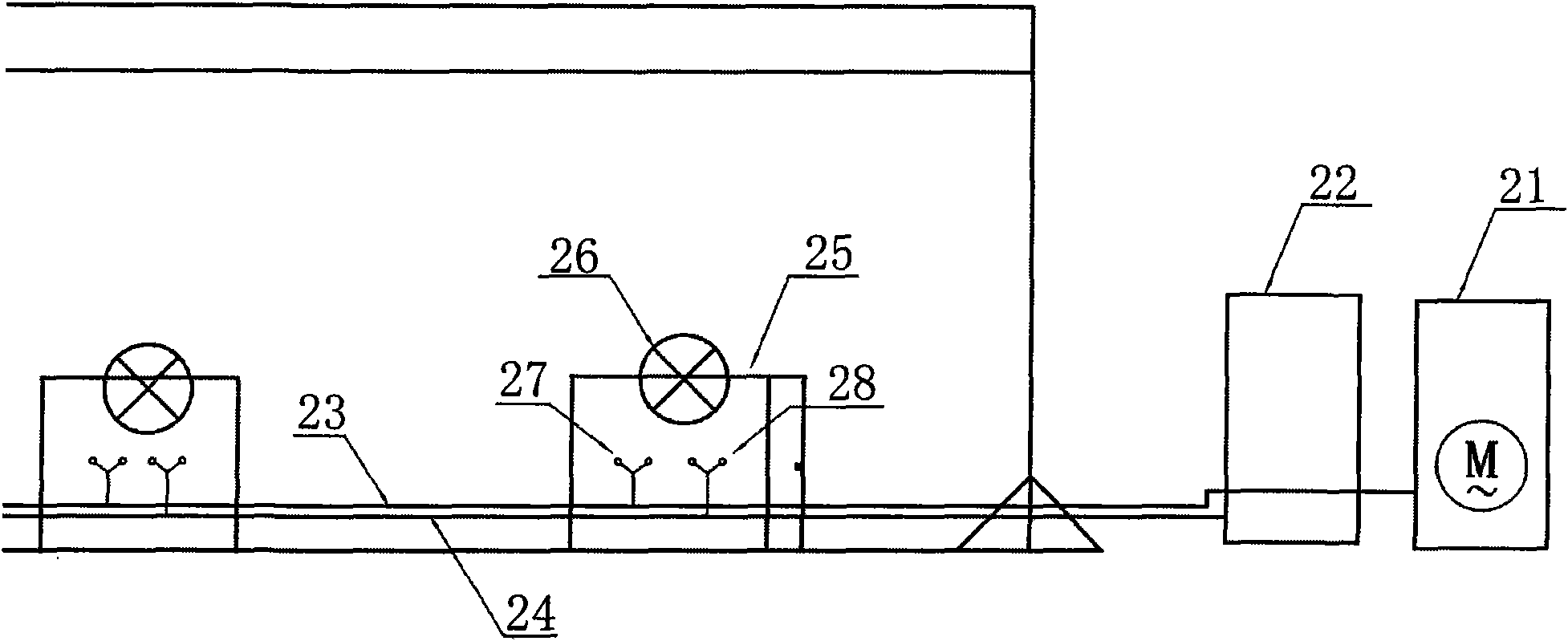

[0034] Such as figure 1 As shown, a method for eliminating volatile organic compounds such as formaldehyde and benzene in furniture of the present invention, its process equipment includes an air compressor 21, a liquid storage tank 22, a gas pipeline 23, a fluid pipeline 24, a workbench 25, and an exhaust fan 26 and spray gun. The elimination agent stored in the liquid storage tank 22 is transported to each group of workbenches 25 through the infusion pipeline 24, and the elimination liquid joint 28 is arranged on the infusion pipeline 24; On the workbench 25 of the group, a compressed air joint 27 is provided on the gas pipeline 23; utilize a spray gun to spray the corresponding type of eliminating agent atomized by high-pressure air to the furniture plate sub-assembly after the machining is completed, and after the painting is completed. The assembled parts, leather materials before assembly, textile fibers, plastics, foam fillers and other surfaces are placed separately i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com