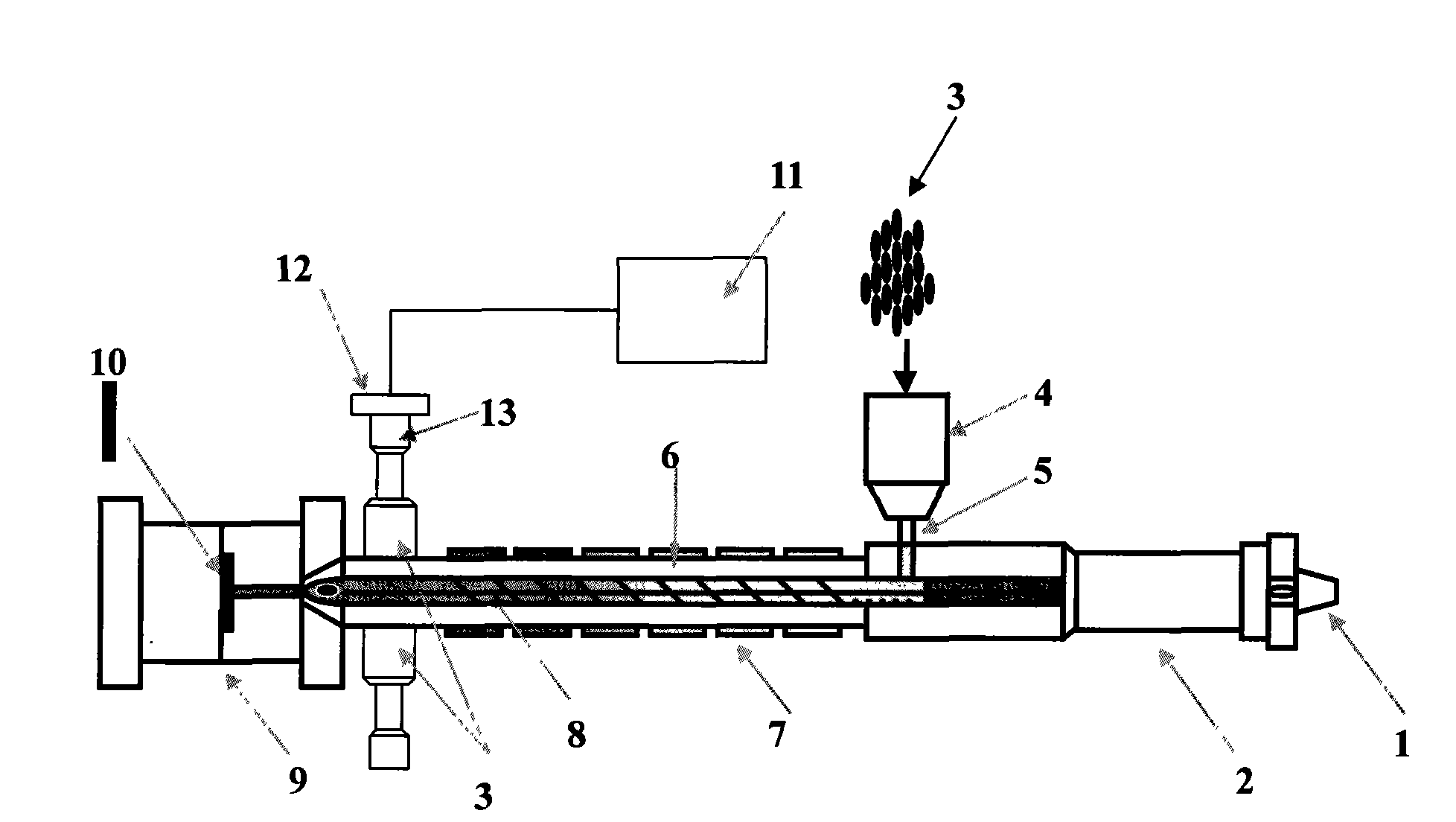

Method and device used for melt injection molding of fully-biodegradable material

A biodegradable material and all-biological technology, which is applied in the field of biodegradable polymer material molding and processing technology, can solve the problems of difficult control and difficulty in processing technology, demoulding mold cleaning, etc., to reduce the phenomenon of sticking screw and barrel, and reduce the use And the effect of convenient maintenance and compact device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Embodiments of the present invention are further described below through examples, but are not limited to these examples.

[0038] The raw material of this embodiment is a fully biodegradable carbon dioxide polymer material, which includes carbon dioxide polymer, polybutylene succinate (PBS), plasticizer, and end-capping agent, and the specific composition parts by weight are : 100 parts by weight of carbon dioxide polymer, 10 parts by weight of polybutylene succinate, 5 parts by weight of acetyl tri-n-butyl citrate, and 1 part by weight of maleic anhydride capping agent.

[0039] The specific molding steps are as follows:

[0040] (1) Stir the raw materials of the above ratio to obtain a blend;

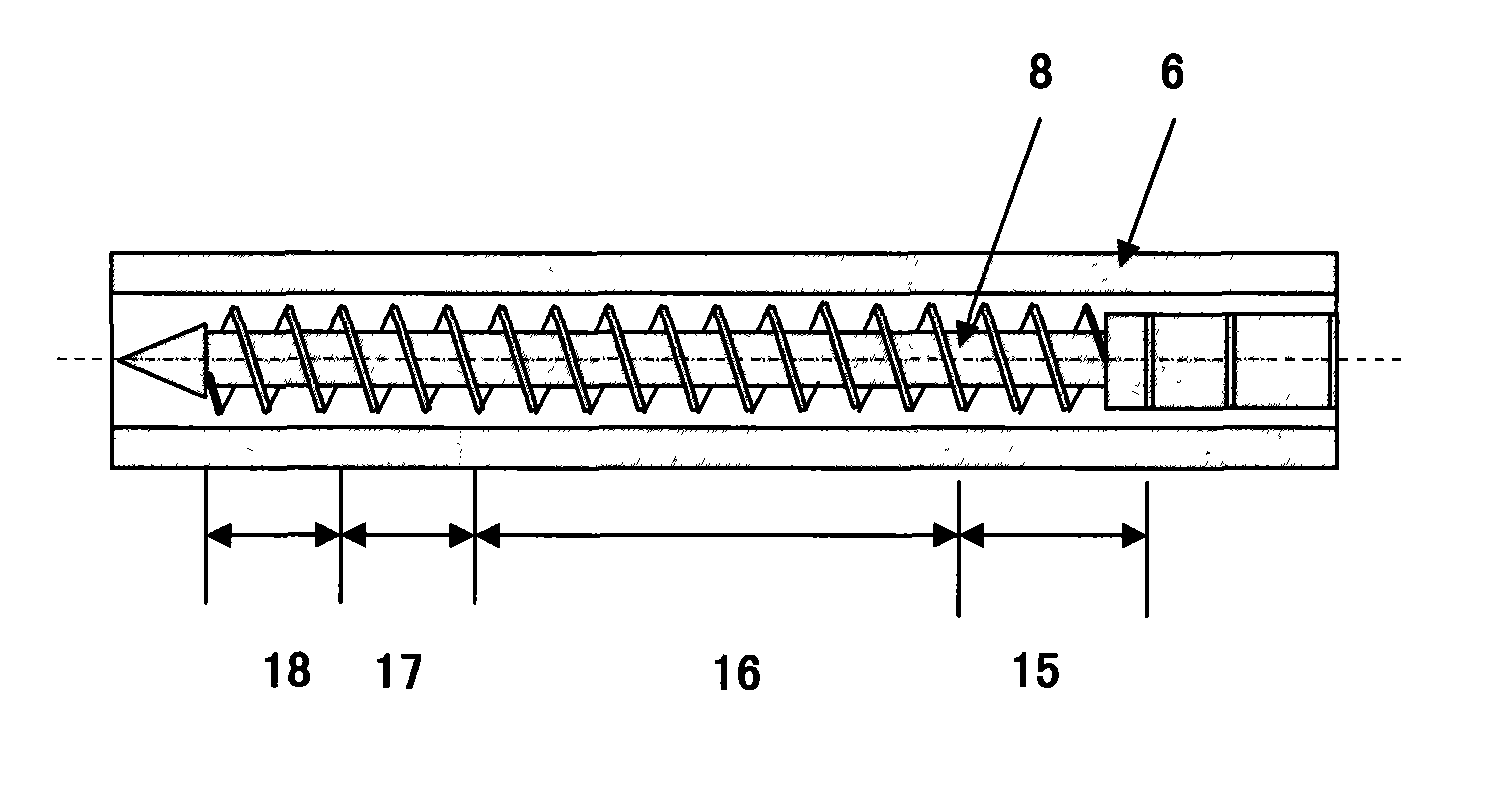

[0041] (2) Send the blended material in (1) into the hopper of the device of the present invention, and the external heater of the barrel is set in a step-by-step heating mode, wherein, the feeding section: 70-100 ° C, the plasticizing section: 130-155°C, extrusion section: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com