Monomeric 7-ethyoxyl ganoderic acid O and separating and purifying method of monomeric 7-ethyoxyl ganoderic acid T thereof

An ethoxylated ganoderma lucidum acid, separation and purification technology, applied in chemical instruments and methods, organic chemistry, steroids and other directions, can solve the problems of high processing temperature, enrichment of impurities, unfavorable stability of biological products, etc., to achieve convenient promotion, Easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

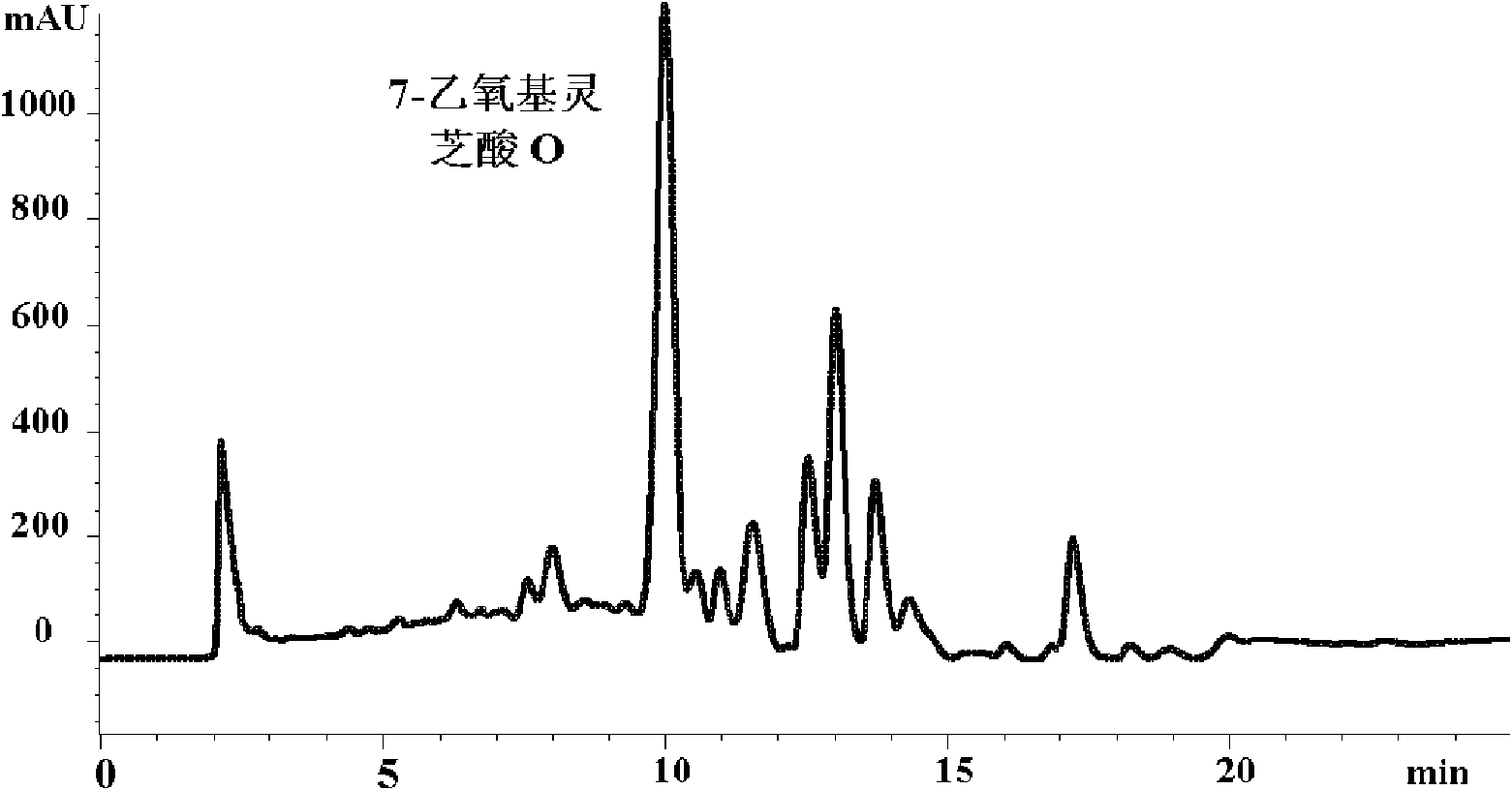

[0054] 1. Weigh 100g of dry cell powder obtained from the fermentation of Ganoderma lucidum mycelium, add 2L of chloroform, extract by ultrasonic for 30 minutes, extract 5 times, filter, and rotary evaporate to obtain 7.3g of extract-like substance, and analyze it by high performance liquid chromatography as follows: figure 1 ).

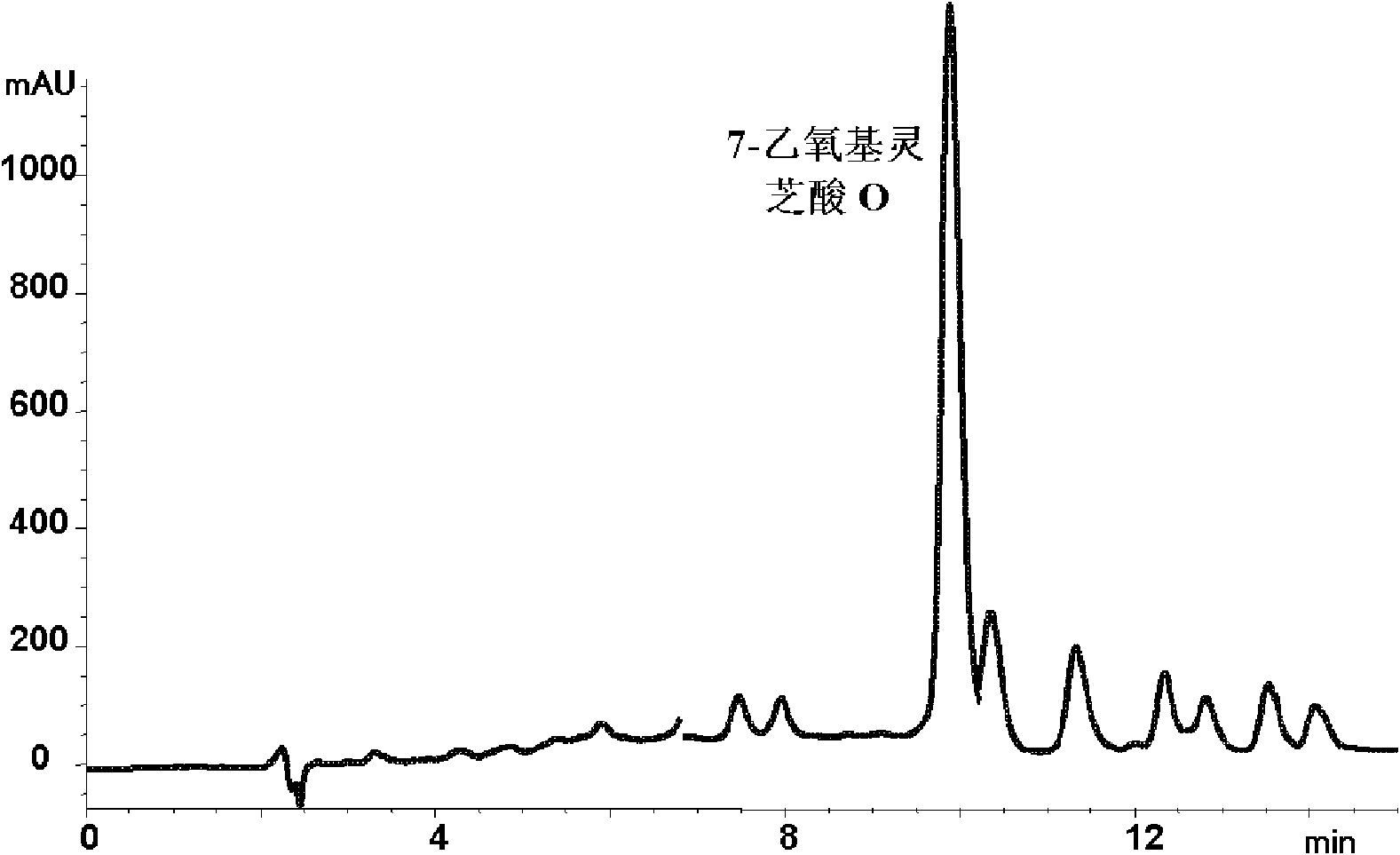

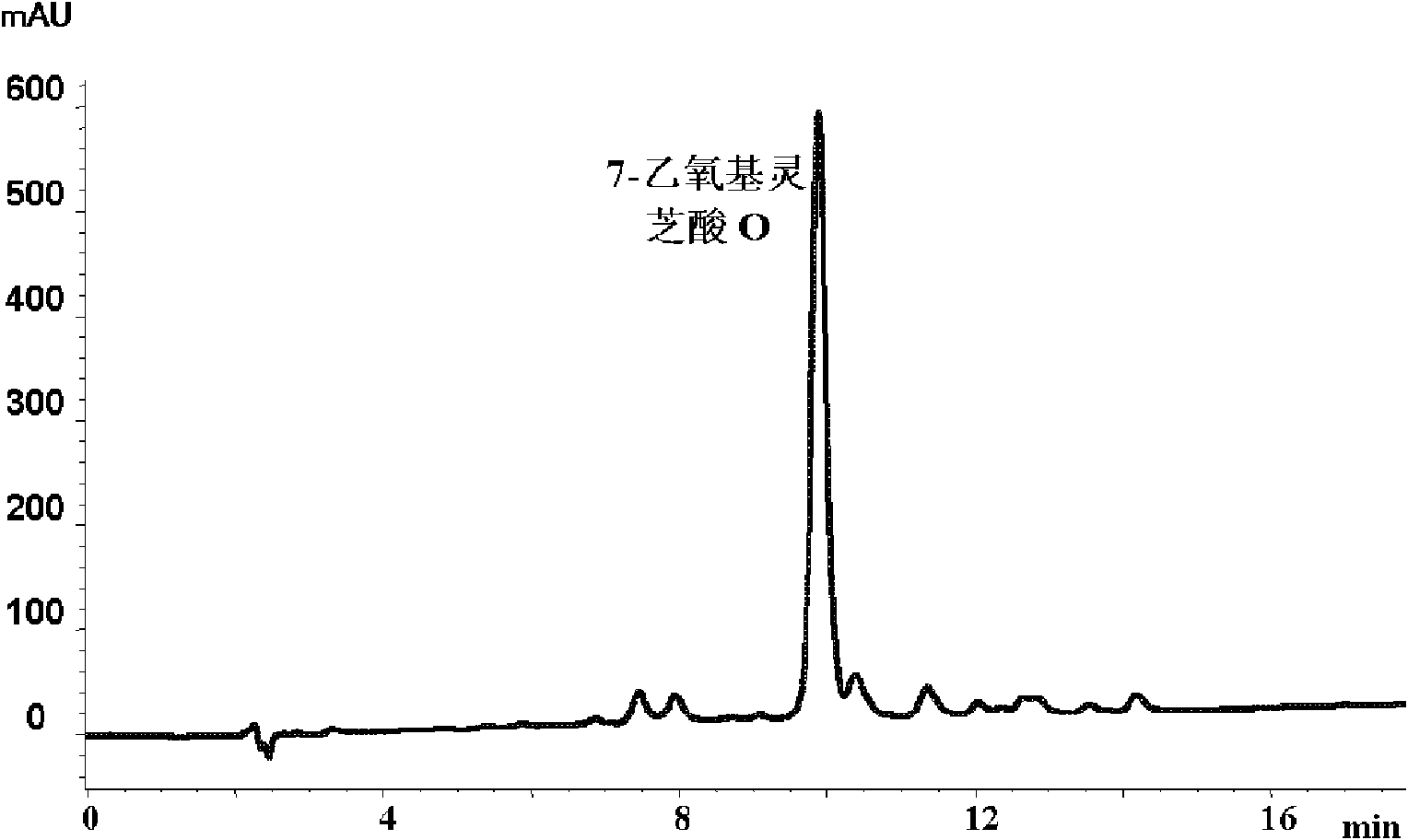

[0055] 2. Dissolve the above-mentioned extract-like substance in 25mL of ether, purify and separate by filling a well-balanced normal-pressure silica gel column in advance, fill with 200g of dry silica gel, the particle size is 200-300 mesh, and the column diameter ratio is 1:10. The diethyl ether of % petroleum ether was used as flow elution, the column volume was about 300 mL, the flow rate was 5 mL / min (full flow rate), and each fraction was collected by an automatic collector. The corresponding components were combined and evaporated to dryness to obtain 3.1 g of solid, which was analyzed by high performance liquid chromatography as figure 2 sh...

Embodiment 2

[0060] 1. Weigh 100g of dry cell powder obtained from the fermentation of Ganoderma lucidum mycelium, add 2L of chloroform, extract by ultrasonic for 30 minutes, extract 3 times, filter, and rotary evaporate to obtain 7.2g of extract-like substance, and analyze it by high performance liquid chromatography as follows: figure 1 shown).

[0061] 2. Dissolve the above-mentioned extract-like substance in 25mL of ether, purify and separate by filling a well-balanced normal-pressure silica gel column in advance, fill with 200g of dry silica gel, the particle size is 200-300 mesh, and the column diameter ratio is 1:10. The diethyl ether of % petroleum ether was used as flow elution, the column volume was about 300 mL, the flow rate was 5 mL / min (full flow rate), and each fraction was collected by an automatic collector. The corresponding components were combined and evaporated to dryness to give 3.1 g of a solid.

[0062] 3. After adding 200mL ether to dissolve the resulting solid, p...

Embodiment 3

[0066] 1. Weigh 100g of dry cell powder obtained from the fermentation of Ganoderma lucidum mycelium, add 2L of chloroform, ultrasonically extract for 30 minutes, extract twice, filter, and rotary evaporate to obtain 7.0g of extract-like substance. HPLC analysis is as follows: figure 1 shown.

[0067] 2. Dissolve the above-mentioned extract-like substance in 25mL of ether, purify and separate by filling a well-balanced normal-pressure silica gel column in advance, fill with 200g of dry silica gel, the particle size is 200-300 mesh, and the column diameter ratio is 1:10. The diethyl ether of % petroleum ether was used as flow elution, the column volume was about 300 mL, the flow rate was 5 mL / min (full flow rate), and each fraction was collected by an automatic collector. The corresponding components were combined and evaporated to dryness to give 3.0 g of a solid.

[0068] 3. After adding 30 mL of ether to dissolve the resulting solid, place it in a crystallizer at -20°C for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com