Chitosan-urea resin microcapsule and synthesis method thereof

A technology of urea-formaldehyde resin and synthesis method, which is applied in the field of microcapsules, which can solve the problems of weak interface binding force, affecting the repair effect of microcapsules, and rupture of microcapsules, and achieves the effects of good stability, low equipment requirements, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

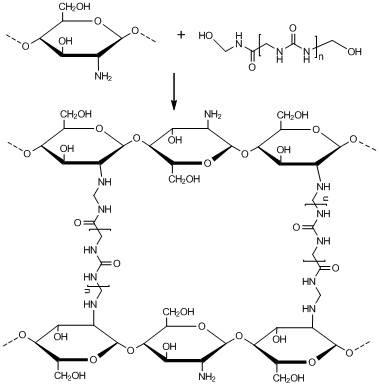

[0015] Specific embodiment one: present embodiment chitosan-urea-formaldehyde resin microcapsule is made up of 3~5 parts of urea-formaldehyde resin prepolymers, 16~24 parts of deacetylated chitosan solutions, 10~20 parts of dicyclopentadiene olefin, 0.03~0.1 part of sodium lauryl sulfate, 0.4~2 part of resorcinol, 0.01~0.1 part of n-butanol and 10~25 parts of deionized water, and the urea-formaldehyde resin prepolymer is made of 8-12 parts of urea and 16-24 parts of formaldehyde solution with a mass concentration of 37% are prepared under the condition of pH value of 8-9.

[0016] The chitosan-urea-formaldehyde resin microcapsules of this embodiment are small white spherical particles with a particle size of 10-160 μm, good stability, and can be stored at room temperature for more than 18 months.

specific Embodiment approach 2

[0017] Specific embodiment two: the difference between this embodiment and specific embodiment one is that chitosan-urea-formaldehyde resin microcapsules are composed of 3.5 to 4.5 parts of urea-formaldehyde resin prepolymer, 18 to 22 parts of chitosan solution in parts by weight , 12~18 parts of dicyclopentadiene, 0.03~0.06 parts of sodium lauryl sulfate, 0.4~0.9 parts of resorcinol, 0.01~0.06 parts of n-butanol and 13~20 parts of deionized water. Other parameters are the same as in the first embodiment.

[0018] The chitosan-urea-formaldehyde resin microcapsules in this embodiment are small white spherical particles with a particle diameter of 30-80 μm.

specific Embodiment approach 3

[0019] Specific embodiment three: what this embodiment is different from specific embodiment one is that chitosan-urea-formaldehyde resin microcapsules are made up of 4 parts of urea-formaldehyde resin prepolymers, 20 parts of deacetylated chitosan solutions, 15 parts of bicyclic Pentadiene, 0.04 parts sodium lauryl sulfate, 0.5 parts resorcinol, 0.02 parts n-butanol and 15 parts deionized water. Other parameters are the same as in the first embodiment.

[0020] The chitosan-urea-formaldehyde resin microcapsules in this embodiment are small white spherical particles with a particle size of 45-55 μm and uniform particle size distribution.

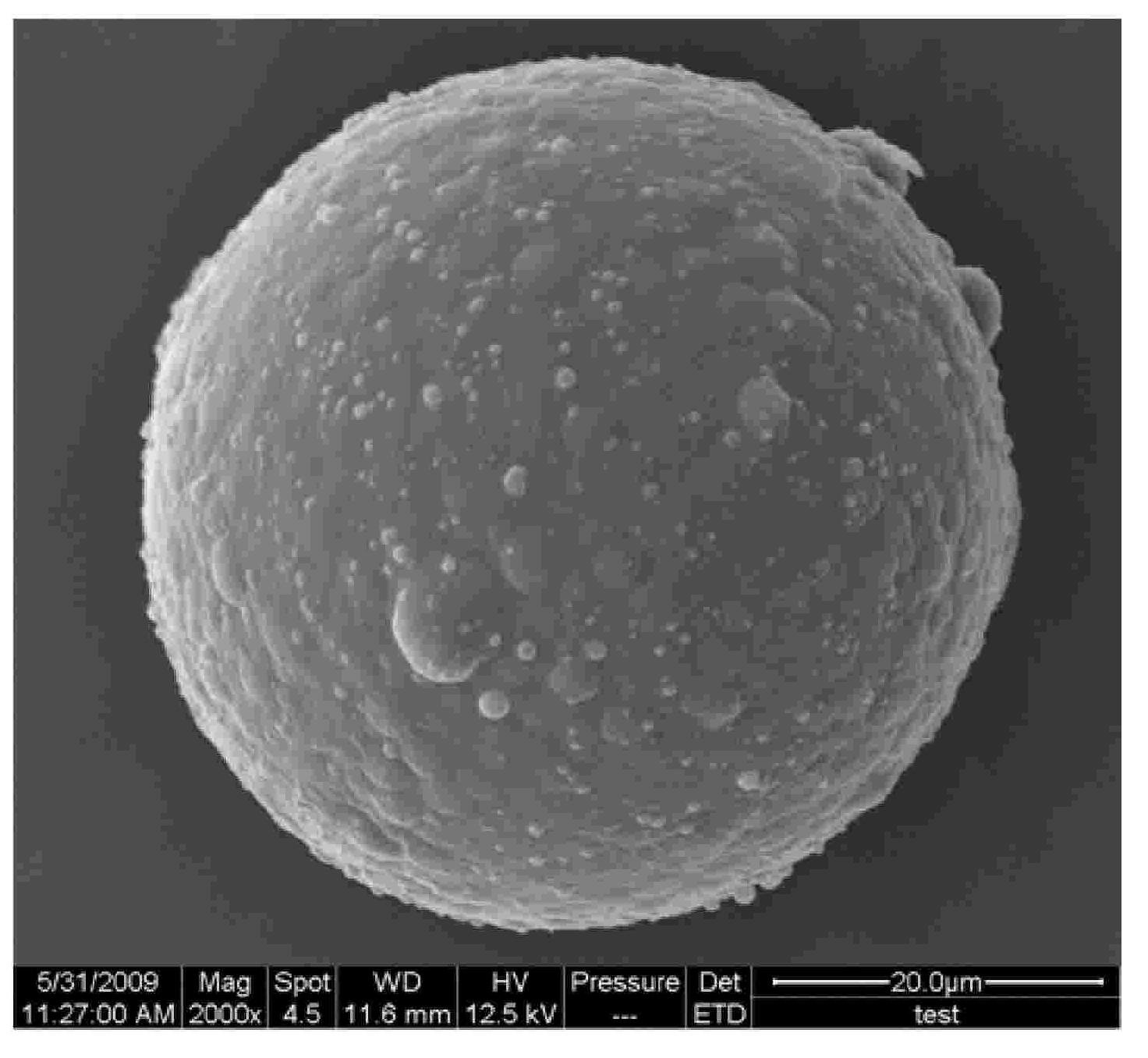

[0021] In this embodiment, chitosan-urea-formaldehyde resin microcapsules are observed with a scanning electron microscope for surface morphology, such as figure 1 shown. Depend on figure 1 It can be seen that the chitosan-urea-formaldehyde resin microcapsules in this embodiment are small spherical particles with a particle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com