Polyvinyl chloride and poly(butylene succinate) sheath-core fiber

A polybutylene succinate, skin-core fiber technology, applied in fiber processing, fiber chemical characteristics, conjugated synthetic polymer rayon, etc., can solve the problems of low molecular weight, yellow color, and not easy to decompose. , to achieve the effect of improving application performance, being beneficial to environmental protection, and reducing energy consumption in printing and dyeing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

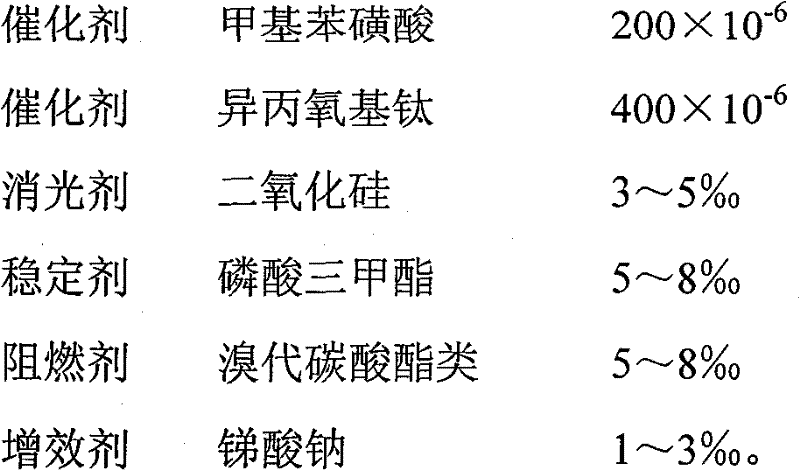

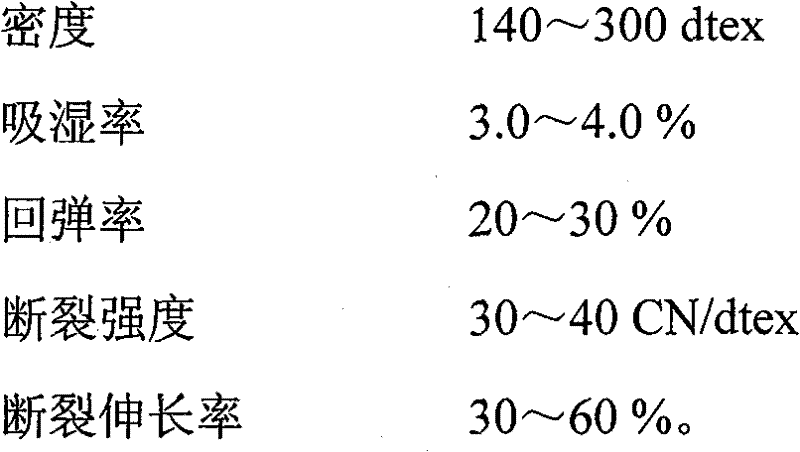

[0029] Preparation of polybutylene succinate: the raw materials are butanediol and succinic acid, the molar ratio of addition is 1.10 to 1.15, the catalyst is toluenesulfonic acid and titanium isopropoxide, and the synthesis of polyester mainly includes Esterification and polycondensation are completed in two steps. In the continuous polymerization process, the esterification reaction is completed through two esterification tanks at normal pressure and reduced pressure, and the polycondensation reaction is completed through two tanks of pre-condensation and final polycondensation. In the synthesis of polybutylene succinate, catalysts, matting agents, stabilizers, synergists and flame retardants should be added. The amount of addition is the molar amount of butanediol. The catalyst and the polymerization raw materials enter into the esterification reaction together, and the matting agent, stabilizer, synergist and flame retardant are added in the final stage of the polycondensat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com