Up-conversion luminescence infrared laser display screen, manufacture method thereof and application thereof

An infrared laser and display technology, which is applied to TVs, instruments, and parts of color TVs, etc., can solve the problems of difficult mass production of laser TVs, complex laser structures, and high costs, so as to save development costs and speed up production. The speed of industrialization and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

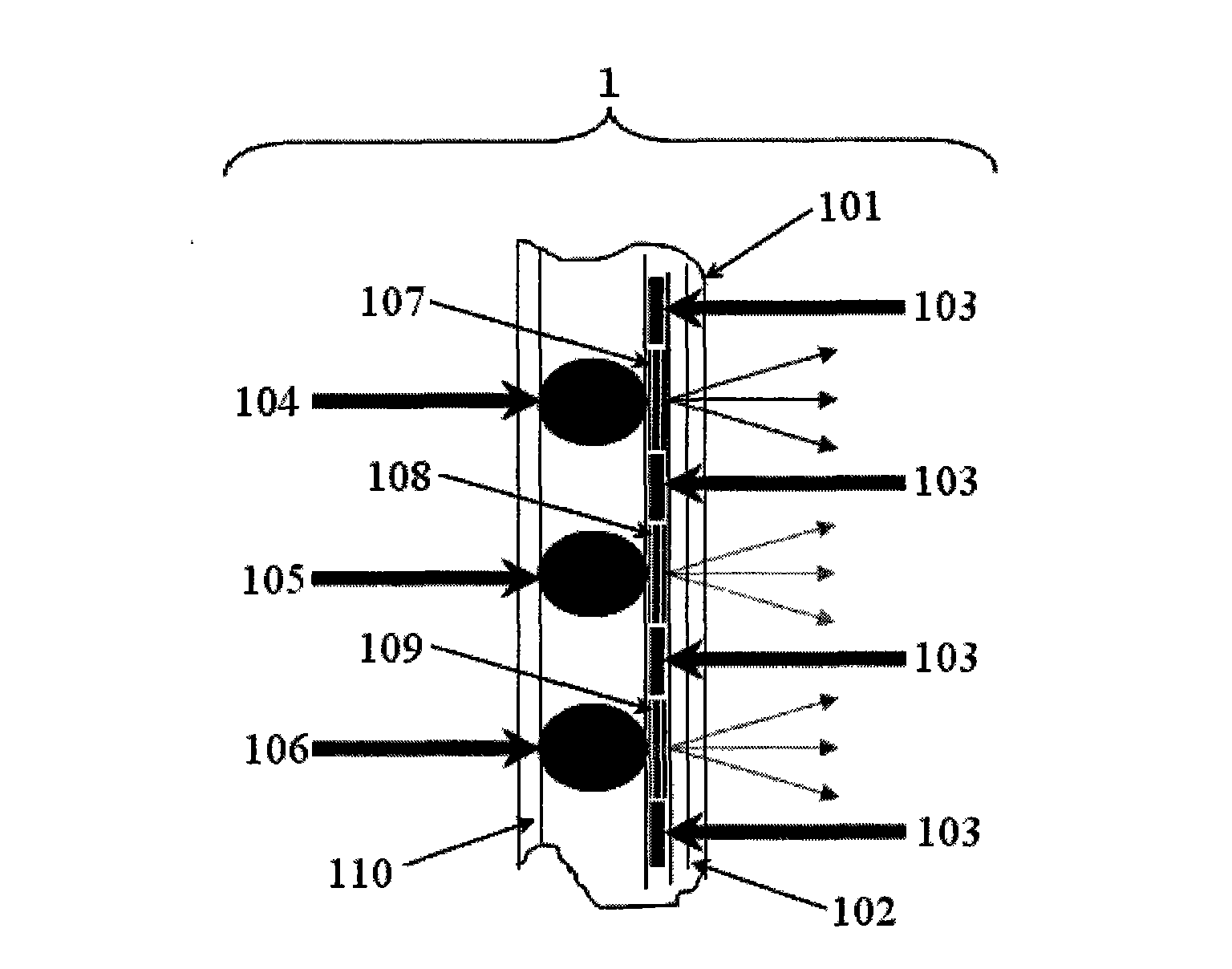

[0033] Such as figure 1 As shown, the manufacturing method 1 of the up-conversion luminescent infrared laser display screen:

[0034] It includes the following steps: the first step is to coat or paste or glue or plate an optical film 102 with high visible light transmission and infrared light (0.8-1.5 μm) high reflection or high absorption on the inner surface of the infrared laser panel 101. The red (R), green (G) and blue (B) three-primary color infrared laser display screen is excited by 0.8-1.5μm LD infrared laser, and there will inevitably be R, G , B. The infrared laser light absorbed by the three primary color luminescent materials emits out of the screen, which is unsafe for human eyes. It is necessary to add an optical film 102 with high transparency of visible light, high reflection or high absorption of infrared light on the viewing side of the screen.

[0035] The second step is to prepare a black matrix 103 on the surface of the optical film 102 through photoli...

Embodiment 2

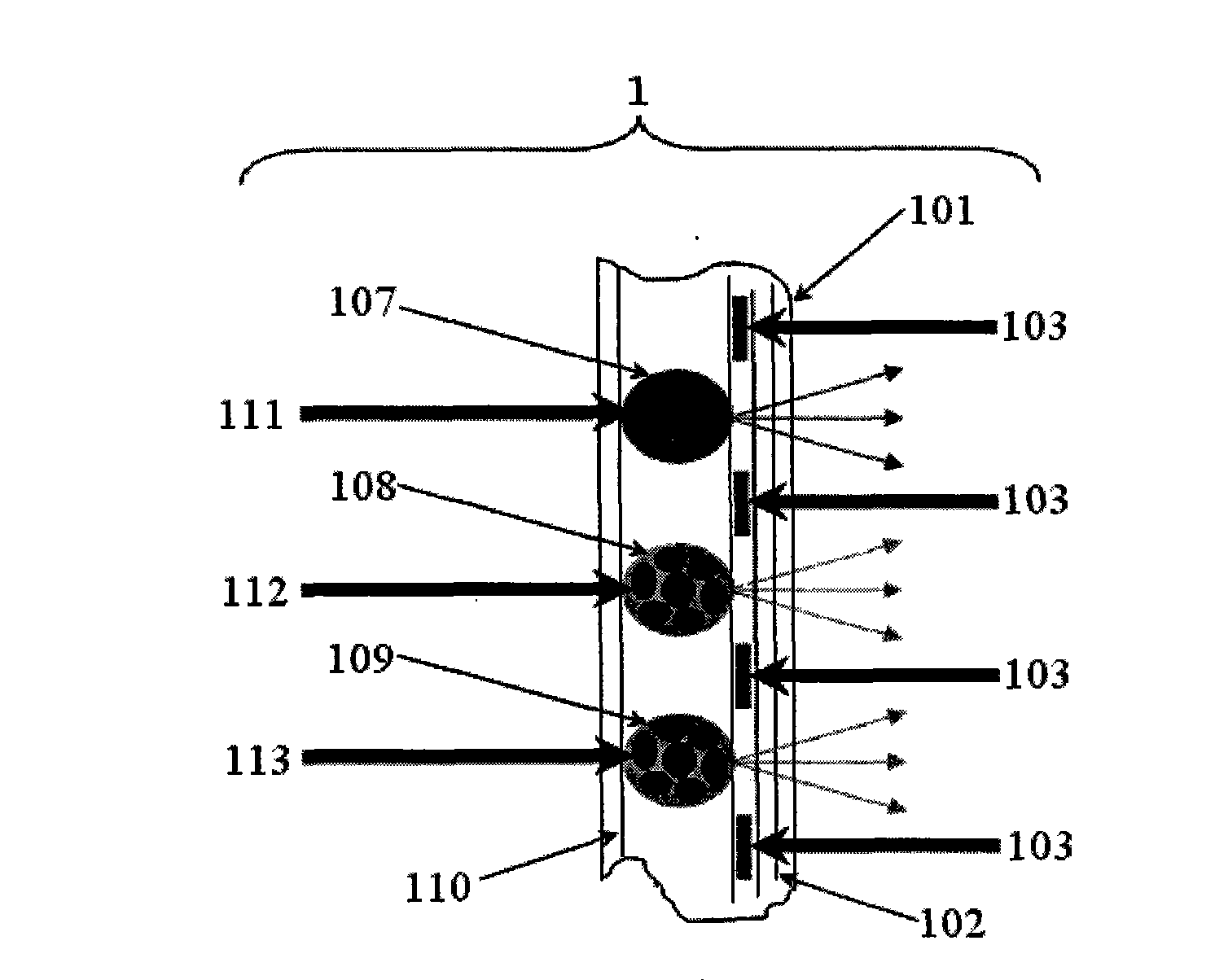

[0110] Manufacturing method 2 of up-conversion luminescent infrared laser display screen:

[0111] Such as figure 2 As shown, in order to simplify the screen-making process, the R, G, and B three-color light sources 104, 105, and 106 described in Embodiment 1 are uniformly mixed with the corresponding color filter films 107, 108, and 109. When G, B three primary color luminescent sources are mixed with the adhesive, corresponding R, G, B color filter films 107, 108, 109 are added at the same time to form the mixed coating paste of luminescent powder and color filter film respectively, and the additional R, G, B three-color luminescent powder with filter function 111, 112, 113. When the three-color light-emitting sources 111, 112, and 113 are used as the coating agent, the three-color pixel primitives are sequentially arranged on the hole array of the black matrix 103, so that there is no need to prepare additional color on the holes of the black matrix 103. filter film. Ex...

Embodiment 3

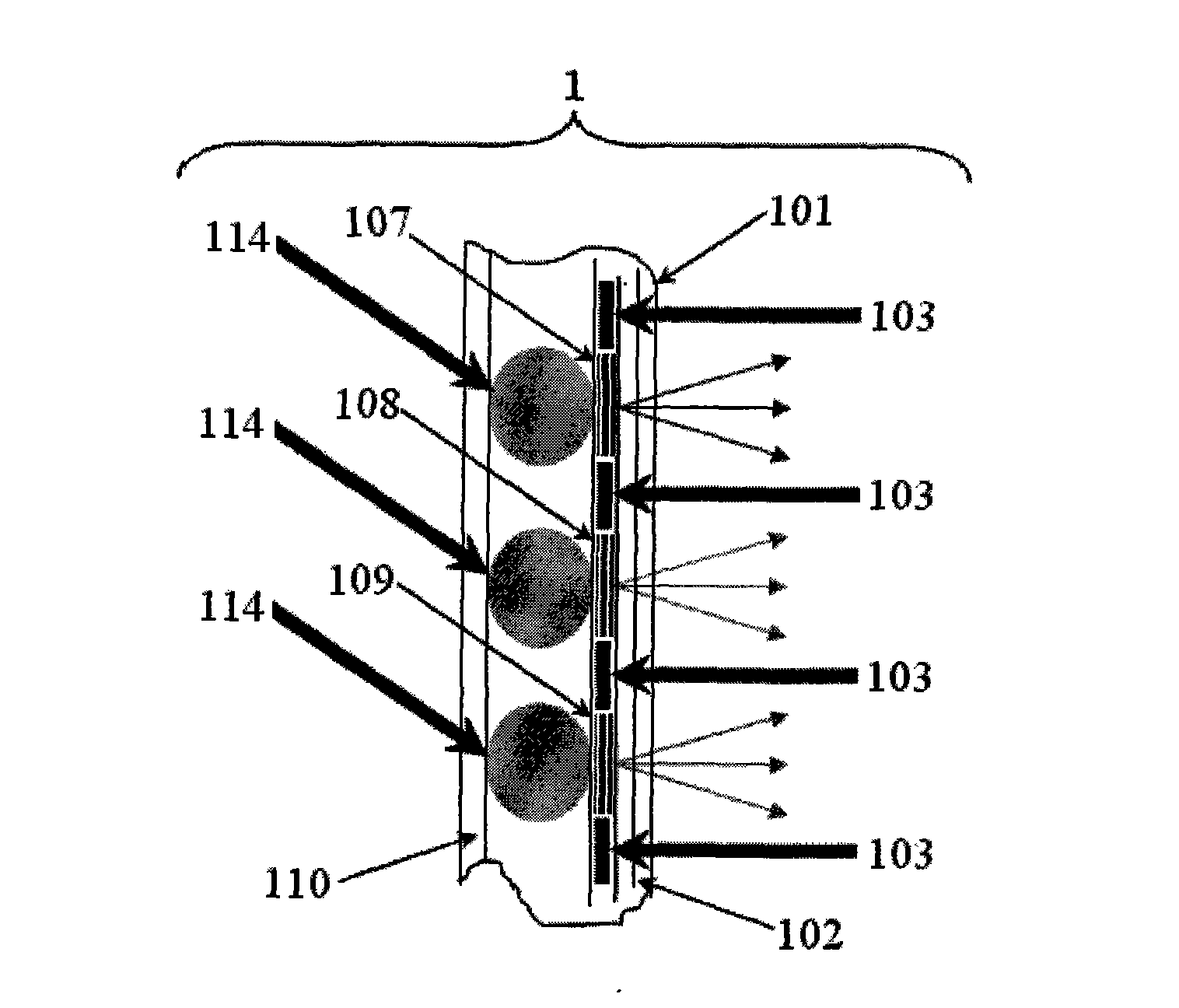

[0113] Manufacturing method 3 of up-conversion luminescent infrared laser display screen:

[0114] Such as image 3 , use the up-conversion white light powder that emits white light by mixing the three-color light source that emits R, G, and B, or the up-conversion white light powder that emits white light by mixing the two-color light source that emits R, G and the light source that emits B unit color Or the white-emitting up-conversion white powder 114 is directly synthesized from a compound to replace R, G, B three-color light-emitting sources 104, 105, 106 have a particle size of 0.5-10 μm. It is a white light source made by mixing the above-mentioned R, G, and B light sources in an appropriate proportion. Miscellaneous, R, G, B full-color luminescence is realized in the same matrix material, and white light is formed, and the CIE (x, y) of the white light emitted is close to the color coordinate value of equal energy white light (0.3333, 0.3333). Its preparation method...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com