Stainless steel with capabilities of high temperature resistance and anti-corrosion, manufacturing method and application thereof

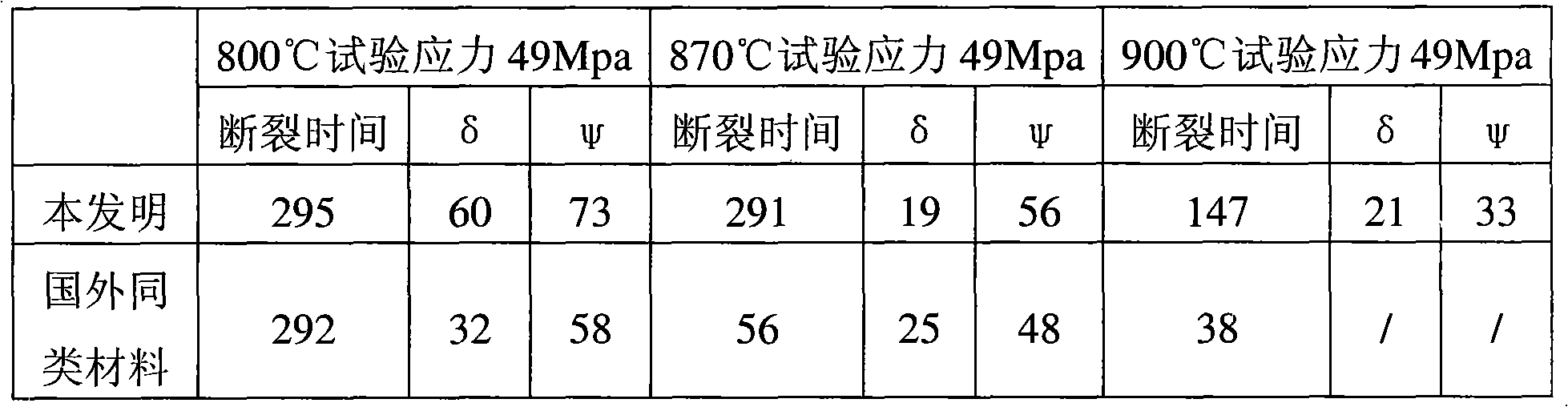

A manufacturing method, stainless steel technology, applied in the field of metallurgy, can solve the problems of high temperature creep resistance and high temperature durability, yield strength, plastic elongation, area shrinkage, low carbide unevenness, and cost increase. Achieve good high-temperature creep performance and high-temperature durability, improve the results of durability tests and creep tests, and improve performance indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

[0034] Select high-quality C, Cr, Ni, Fe and other metal raw materials for vacuum smelting. When the vacuum degree reaches ≤2.7Pa, the power can be increased for melting; during the refining period, the vacuum degree should reach 2.7Pa as much as possible, the molten pool is calm, and the refining is 25 minutes. After refining, close the vacuum valve and fill with Ar6666pa, add Si, Mn, Nb, V, C, Nb, V respectively at 0.10%, slowly add in batches when adding alloy materials, after one alloy is melted, add the following an alloy. After the feeding is completed, after the C is melted, the high and low power are alternately stirred, and the steel is tapped 10 minutes after the C is melted, and the temperature is measured and sampled before tapping. The tapping temperature is 1520±10°C, filled with Ar to protect the pouring, and pouring φ325 electrodes.

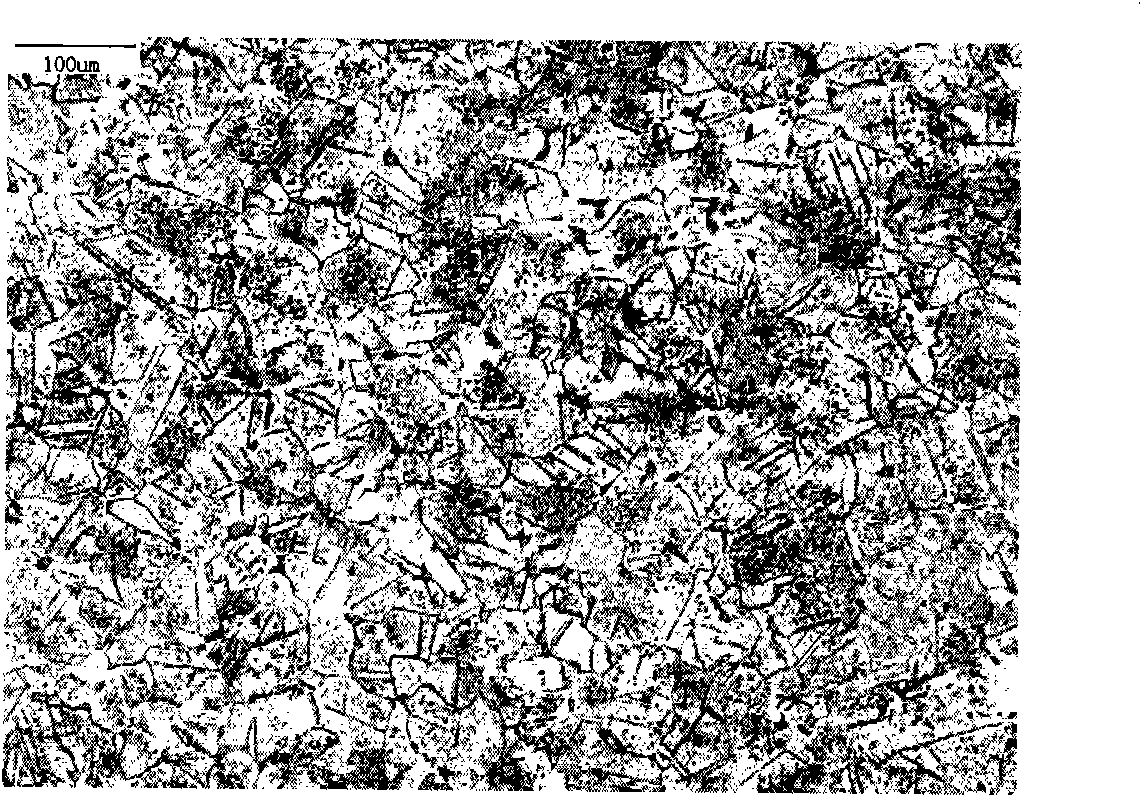

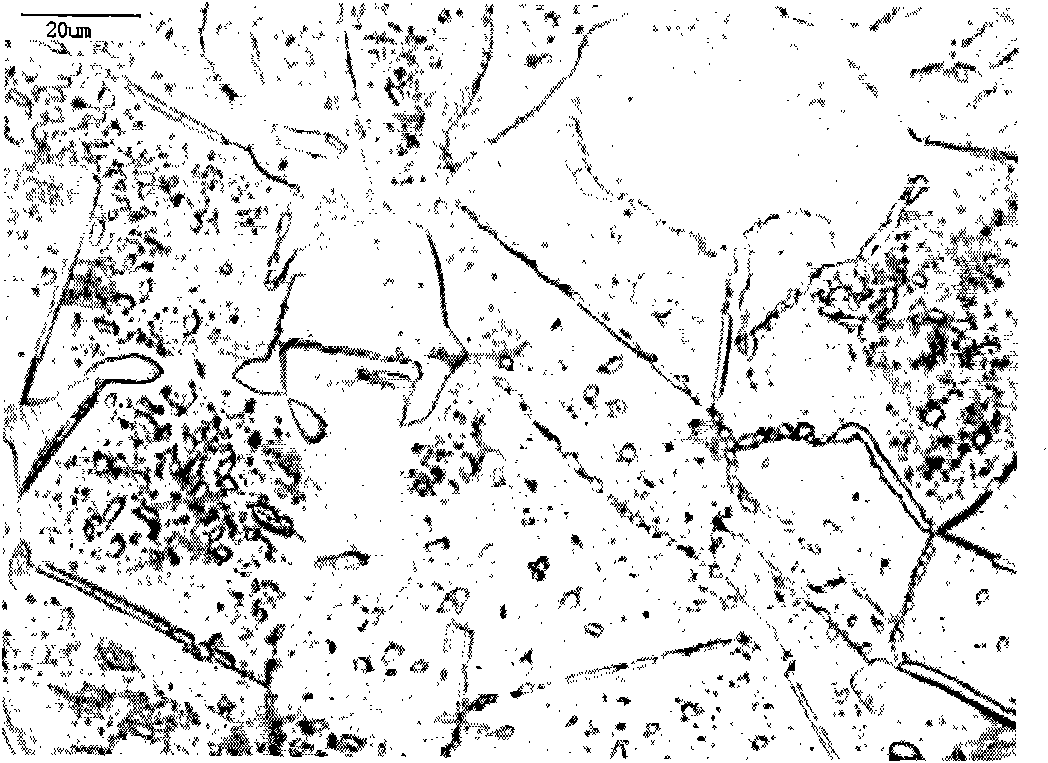

[0035] Using notoginseng slag system (CaF 2 :Al 2 o 3=70:30) remelting electroslag into φ500 electroslag ingot, forging hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com