Nano magnetic material of surface modified boric acid base group, preparation method and application thereof

A nano-magnetic material and boric acid group technology, applied in the direction of iron oxide, iron oxide/iron hydroxide, etc., can solve problems such as cumbersome operation, and achieve the goal of solving difficult analysis, simple and effective synthesis method, good practical value and application prospect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

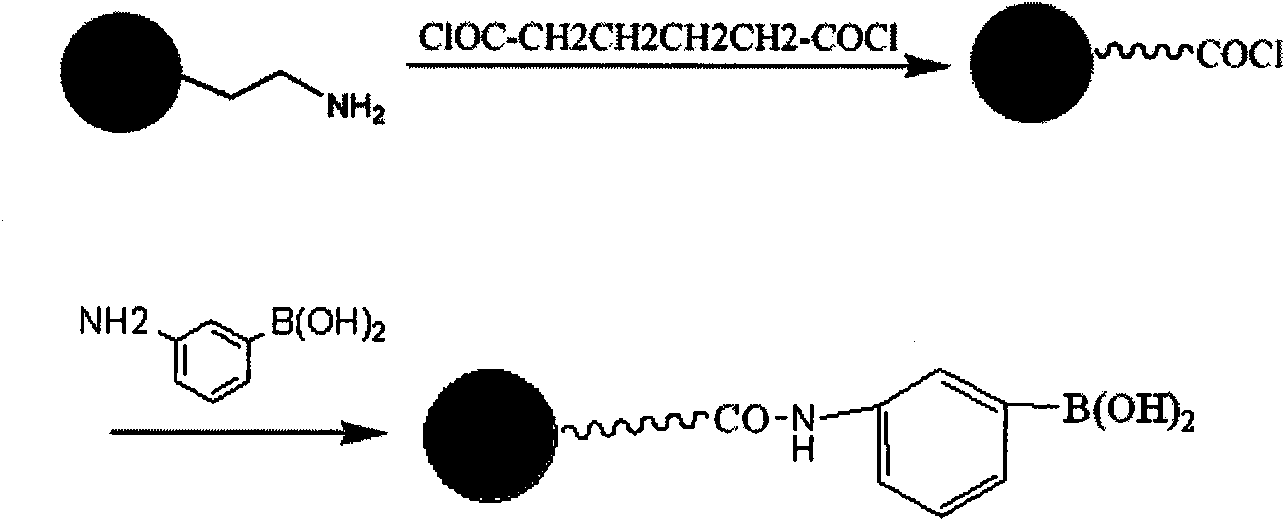

[0027] Embodiment 1 surface modification Cu 2+ Synthesis of Magnetic Materials

[0028] The synthesis of the surface-modified Cu2+ magnetic material is through the following steps:

[0029] Synthesis of superparamagnetic nanoparticles of ferric oxide with amino groups on the surface by hydrothermal method:

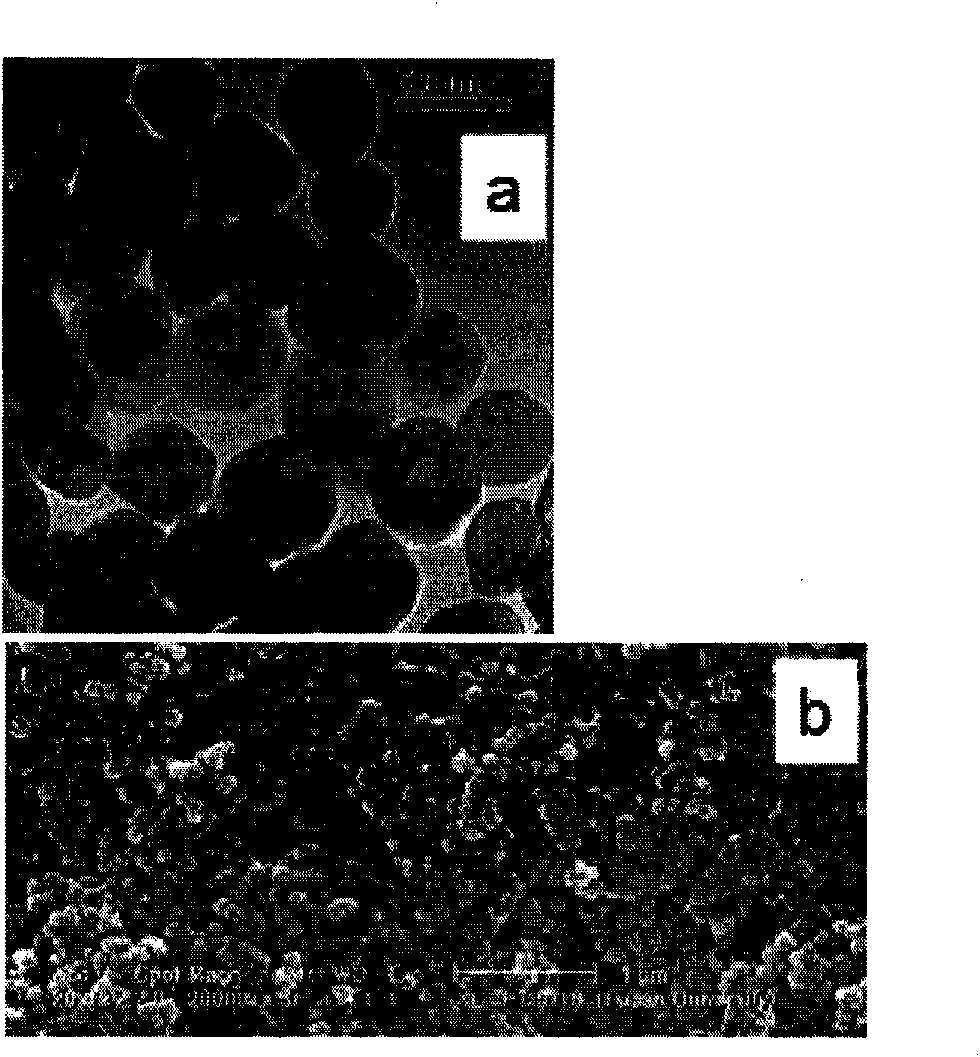

[0030] Using 3.0 grams of FeCl3·6H2O as the raw material, 80-90mL of ethylene glycol as the dispersion system, adding 6-12 grams of anhydrous sodium acetate, 10-20 grams of 1,6-hexamethylenediamine, the reaction temperature is 195-200 ° C, The reaction time is 4-6 hours, and the magnetic nanoparticles with amino groups on the surface are generated, and the particle size is 20-100nm;

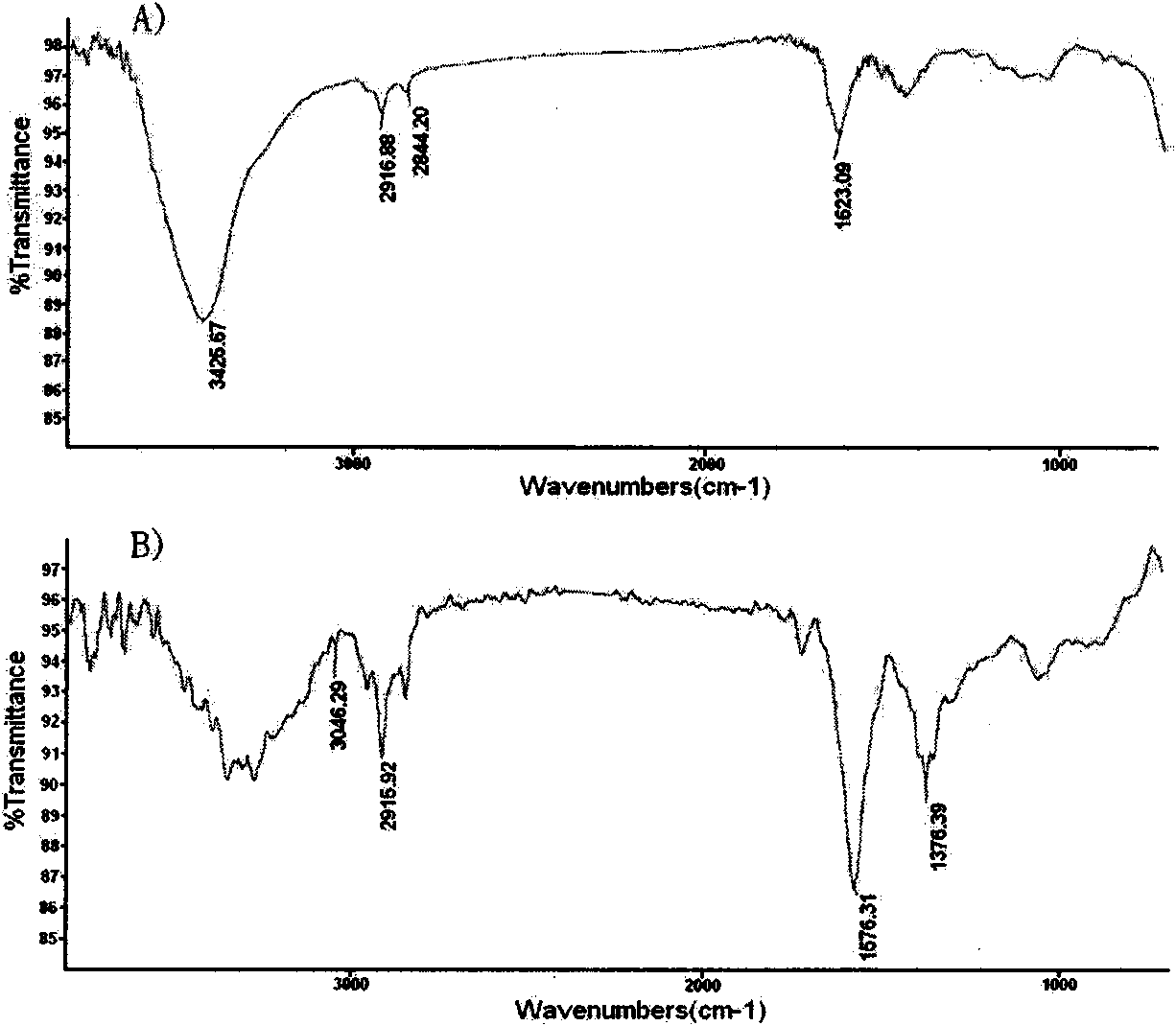

[0031] Fe will be synthesized by step (1) 3 o 4 Amino magnetic microspheres are repeatedly washed with deionized water to remove water-soluble impurities, and finally the product is vacuum-dried at 40-50°C to obtain black powder; secondly, the surface of Fe3O4 amino magnetic microspheres ...

Embodiment 2

[0033] Example 2 The surface-modified Cu2+ magnetic material is used for peptide enrichment

[0034] (1) Enzymatic hydrolysis of protein solution:

[0035] 100 μg of asialofetuin was dissolved in 50 mM NH4HCO3 solution (pH 8) at a concentration of 50 ng μl-1, denatured with 10 mM dithiothreitol (60 °C, 30 min), and alkylated with 100 mM iodoacetamide ( 37°C, 45min), trypsin was digested at 37°C overnight, and the enzymatic solution was frozen at -80°C until use.

[0036] (2) Separation and enrichment of peptides:

[0037] 100 μL of glycoprotein hydrolyzate with a concentration of 5ng μL-1 was reacted with about 100ng of magnetic nanomaterials for 90 minutes under continuous shaking, and the reaction system was an NH4HCO3 solution with a pH of about 8.5. Then, the material bonded to the glycopeptide after the reaction was washed 2-3 times with NH4HCO3 solution with a pH of about 8.5, 20 μL each time. The rinse solution was blotted dry and eluted with 10 μL of trifluoroacetic a...

Embodiment 3

[0040] Example 3 The magnetic material with surface-modified boronic acid groups is used for the separation of glycoproteins

[0041] Take 2 μL of glycoprotein (1 μg μL-1), mix with 2 μL of non-glycoprotein (1 μg μL-1), and react with nanomaterials in a solution with a pH of about 8.5 under the conditions of Experiment 2, and the obtained eluate is mixed with untreated The original control solution was subjected to 12% SDS-polyacrylic acid electrophoresis separation. The resulting strips were scanned and analyzed after silver staining.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com