Low-refractive index film, method for forming the low-refractive index film, and antireflection film

A low-refractive-index film and deposition method technology, applied in the field of anti-reflection films, can solve the problems of difficult deposition of anti-reflection films and low-refractive-index films, and achieve the effects of uniform anti-reflection function and good anti-reflection function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

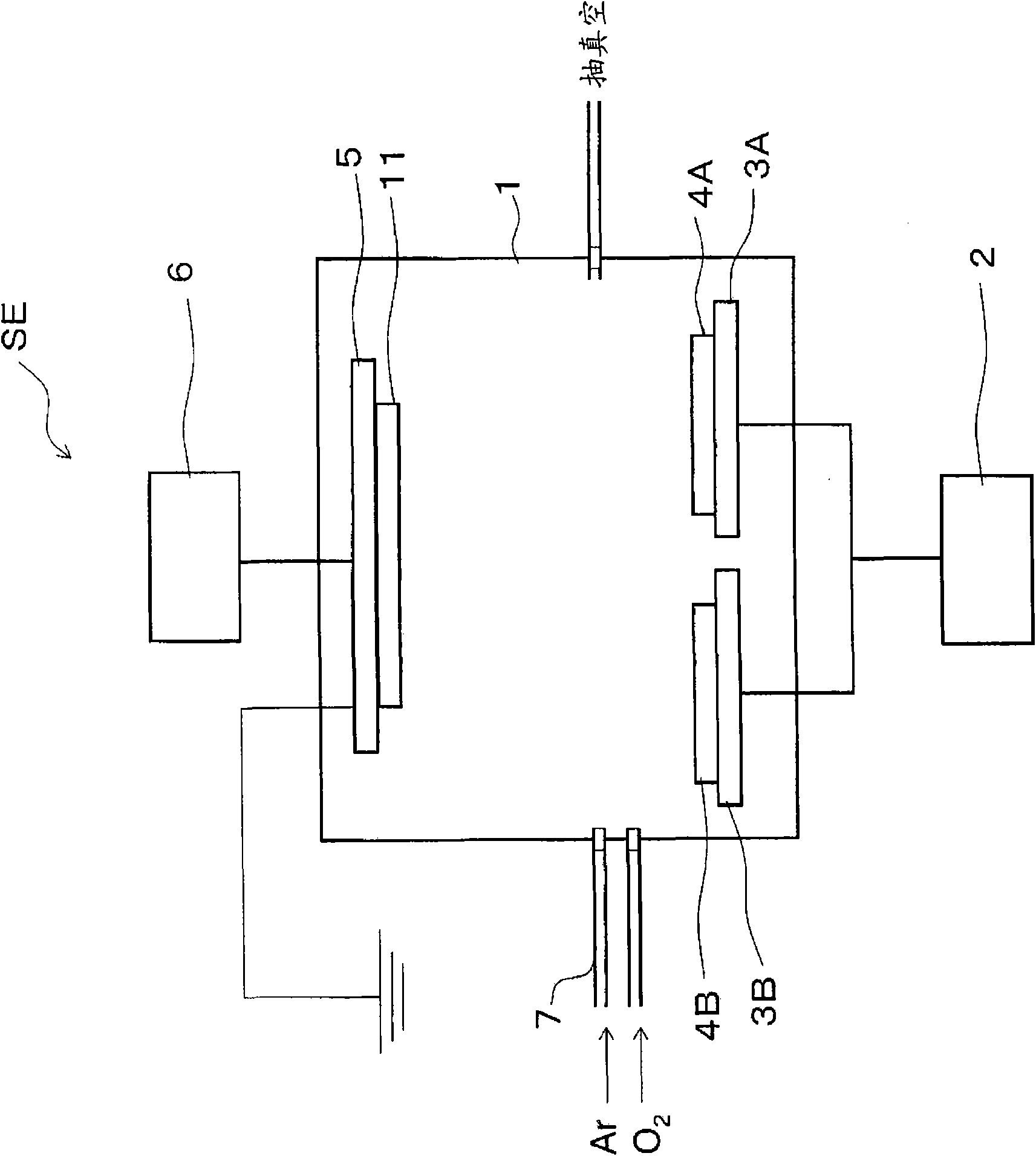

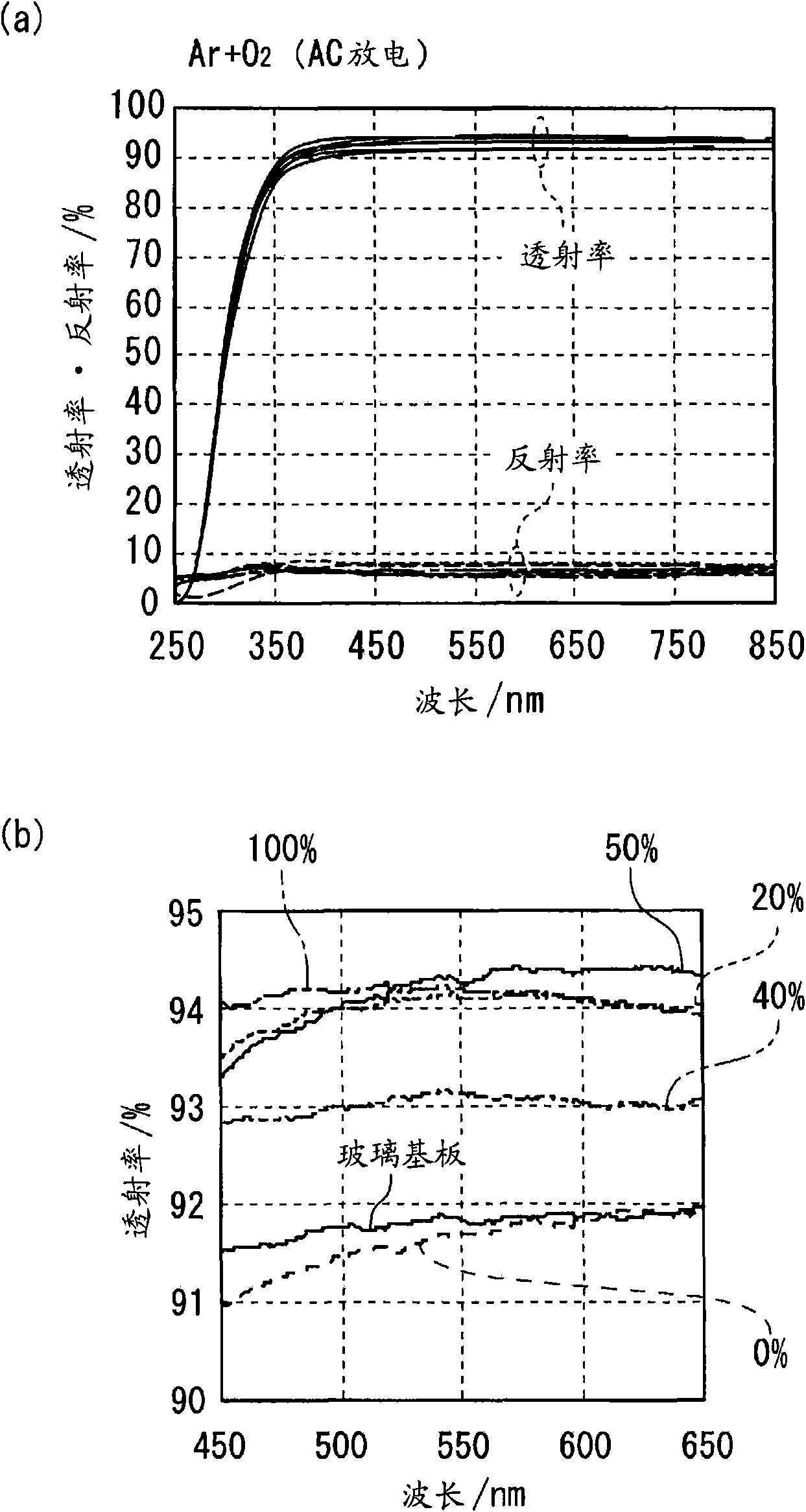

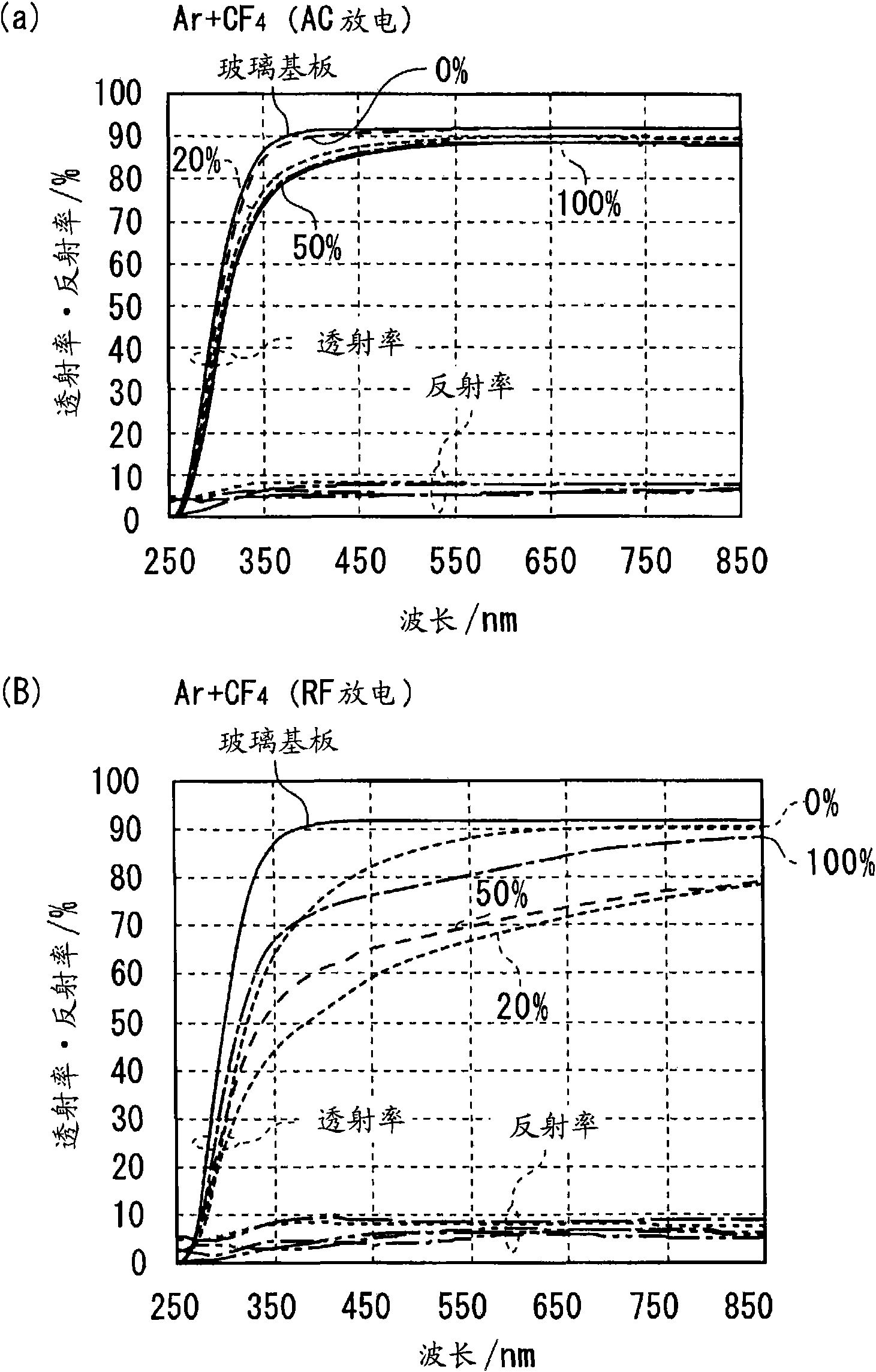

[0040] will be used for figure 1 The reactive sputtering apparatus SE shown, an example of depositing a low-refractive-index film by the method for depositing a low-refractive-index film of the present invention will be described. It should be noted that regarding sputtering conditions, targets 4A and 4B were used: MgF 2 -SiO 2 Sintered body (MgF 2 : SiO 2 =70:30 atomic percent); sputtering gas: Ar; and reaction gas: O 2 As a common condition, and with vacuum chamber 1 inside 5 x 10 -4 Ar gas is introduced at a back pressure below Pa, and pre-sputtering is performed. Subsequently, a low-refractive-index film was prepared under the following deposition conditions. It should be noted that (O 2 Gas flow ratio) = (O 2 gas flow) / {(O 2 Gas flow)+(Ar gas flow)}×100(%).

[0041] (deposition condition)

[0042] Substrate 11: transparent glass substrate

[0043] ·O 2 Gas flow ratio: 0%, 20%, 40%, 50% and 100%

[0044] · Frequency of AC power supply: 90kHz

[0045] ·Suppli...

Embodiment 2

[0097] will be used for figure 1 An example of the deposition of an anti-reflection film is described using the reactive sputtering apparatus SE shown.

[0098] Here, based on the following respective deposition conditions, a film having Figure 4 Anti-reflective coating of the structure shown.

[0099] (1) Substrate: glass substrate

[0100] (2) Adhesive layer: SiO x

[0101] Sputtering target: Boron-doped polysilicon

[0102] · Sputtering gas: Ar

[0103] Reactive gas: O 2

[0104] (3) High refractive index layer a: Nb 2 o 5

[0105] Sputtering target: metal Nb

[0106] · Sputtering gas: Ar

[0107] Reactive gas: CO 2

[0108] ·Film thickness: 25nm

[0109] (4) Low refractive index layer a: MgF 2 -SiO 2

[0110] · Sputtering targets 4A and 4B: MgF 2 -SiO 2 Sintered body (MgF 2 : SiO 2 =70:30 atomic percent)

[0111] · Sputtering gas: Ar

[0112] Reactive gas: O 2

[0113] Deposition conditions: same as those used in the fourth sample of Example 1

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com